Novel building masonry knife

A technology for building and laying knives, which is applied in the field of new building knives, can solve the problems of cracking of the hand tiger's mouth, high labor intensity, uncomfortable operation, etc., and achieves the effect of improving comfort, reducing labor intensity, and avoiding littering everywhere.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

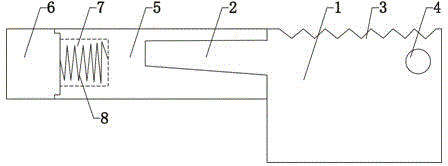

[0011] see figure 1 , the new construction knife includes a knife body 1 and a knife handle 2, and also includes a handle 5, the knife handle 2 is arranged in the handle 5, a groove 7 is recessed at the tail end of the handle 5, and the groove 7 is peripherally arranged There is an auxiliary handle 6, the auxiliary handle 6 is threadedly connected with the handle 5, a thin wire 8 is arranged in the groove 7, one end of the thin wire 8 is fixed in the groove 7, and the other end is fixed in the auxiliary handle 6, on the knife back of cutter body 1, be provided with toothed auxiliary knife edge 3, the thickness of this toothed auxiliary knife edge 3 top surfaces is 0.5 millimeter, is provided with hanging hole 4 at cutter body 1 front portion.

[0012] The present invention adds a handle 5 on the knife handle 2, so that the operating comfort and shock resistance are greatly improved; an auxiliary handle 6 and a thin line 8 connecting them are arranged on the handle 5, and when ...

Embodiment 2

[0014] The thickness of the top surface of the tooth-shaped secondary knife edge 3 is 2.5 millimeters, and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com