Insulation transfer ladder and working method for live maintenance of ±800kv DC line

A live maintenance and DC line technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as very high physical fitness requirements, increased length of insulator strings, and increased distance between insulator strings, so as to reduce the number of power outage maintenance and solve the problems of insulator strings. String length, improve the effect of combination gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

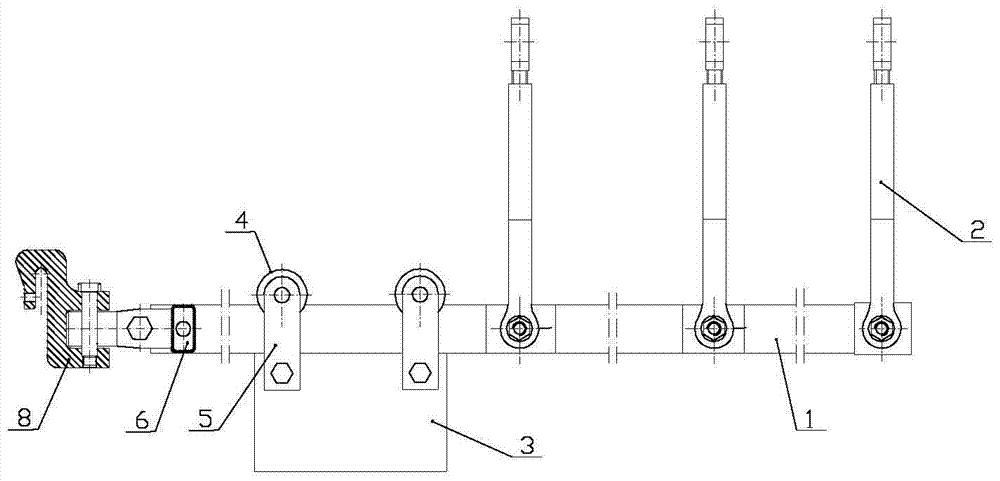

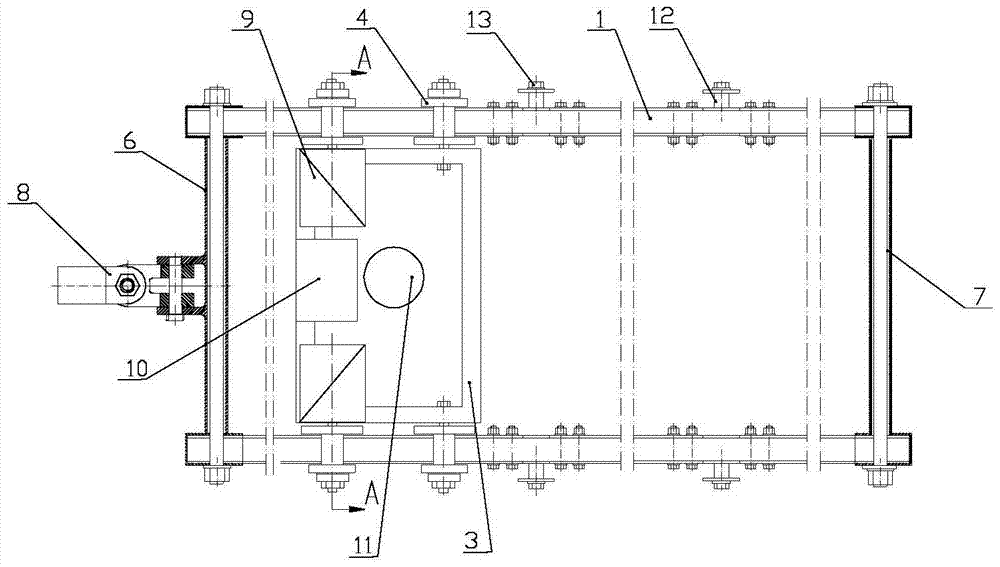

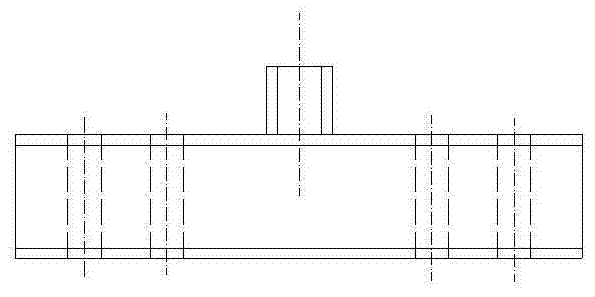

[0030] Such as figure 1 , figure 2 , Figure 5 and Image 6As shown, the insulating rotary ladder for live maintenance of ±800kV DC transmission line includes two parallel insulating side beams 1, upper crosspiece 7, lower crosspiece 6, rotating base 8, bow spreader 2, electric block 3 and insulating rope 20 , specifically: the upper crosspiece 7 and the lower crosspiece 6 are fixed to the upper and lower ends of two parallel insulating side beams 1 through connecting bolts; the insulating turntable is connected to the pole tower 16 through the rotating base 8, and the insulation turntable 16 can rotate up and down, left and right, wherein, one end of the rotating base 8 is hinged with the lower crosspiece 6, and the middle part of the lower crosspiece 6 is provided with a connecting projection connected to the rotating base 8, and the connecting projection is provided with a connecting piece connected with the rotating base 8. One end of the rotating base 8 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com