Cable Termination Anti-twist

A technology of cable terminal and anti-twist device, which is applied in the direction of cable terminal, etc., can solve the problem that the cable terminal is easy to twist and damage the lead lining effect, and achieve the effect of avoiding twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

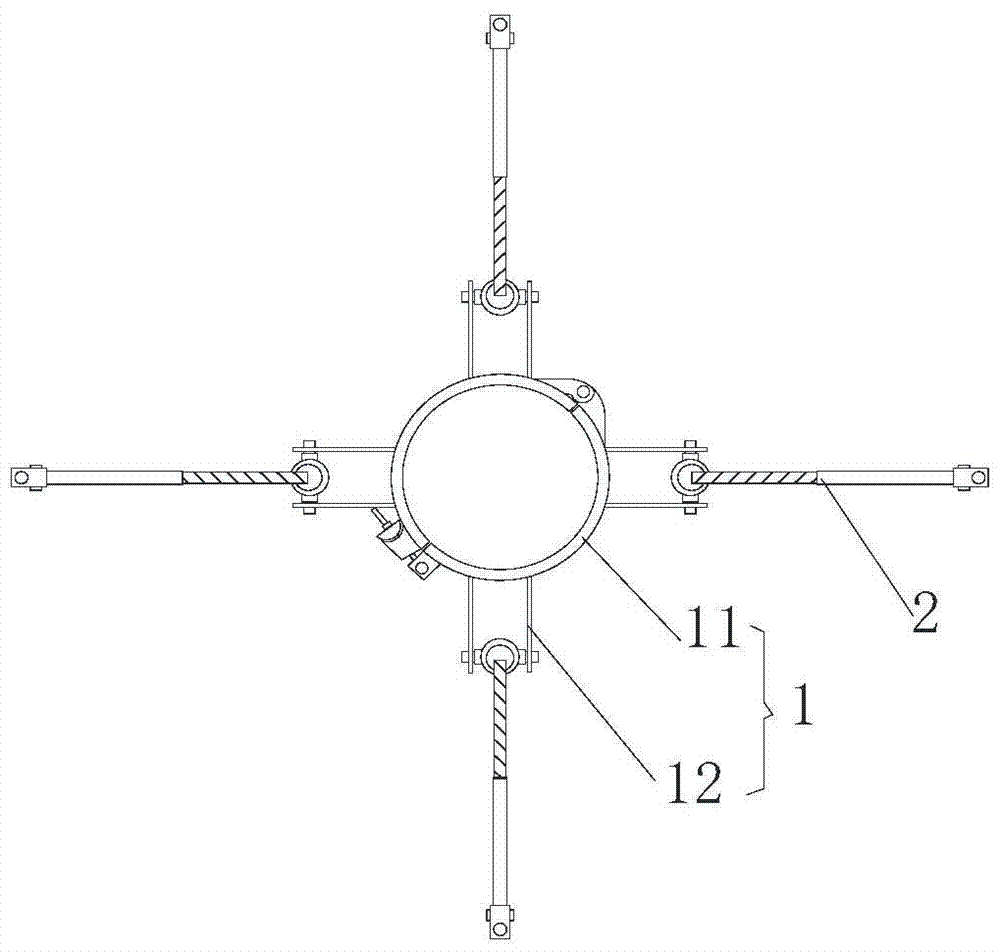

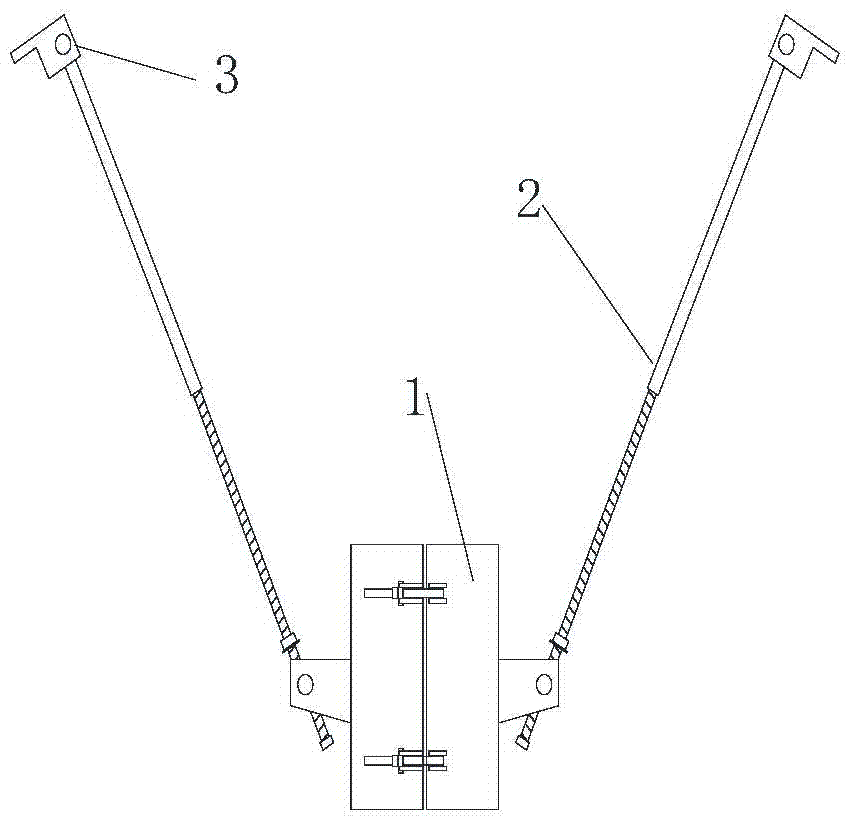

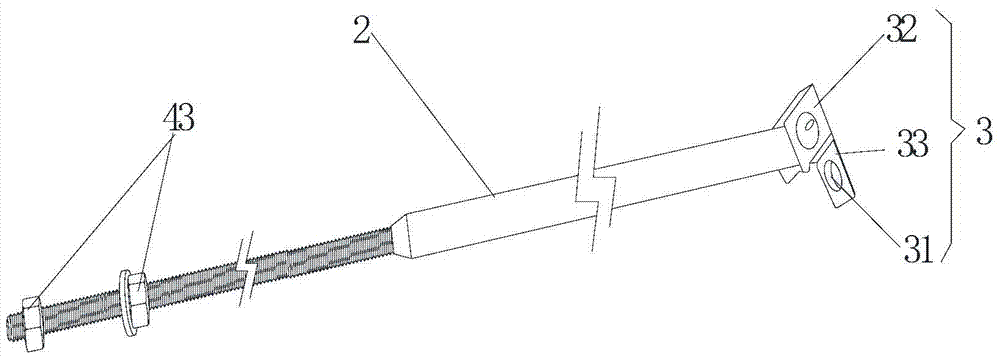

[0023] As described in the background technology, when the cable terminals in the prior art are installed, due to the complexity of the construction site and the volume and weight of the assembled cable terminals, when the installation distance of the cable through the warehouse is too long, etc. In this case, it is very easy to cause the cable terminal to bend, and the cable terminal bumps into the cable compartment, thereby destroying the lead filling effect and the position of the stress cone, that is, there is a problem that the cable terminal is easy to twist and destroy the lead filling effect. In order to solve the above problems, in a typical implementation of the present application, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com