Uv compositions having low active concentrations and high in vivo spf

A technology of active substances and compositions, applied in the field of stable combination of UV active ingredients, can solve problems such as incompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

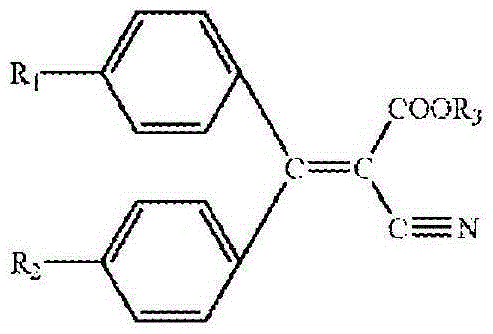

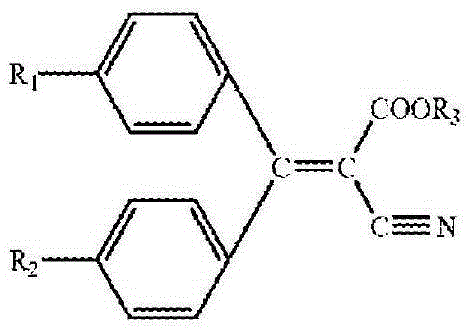

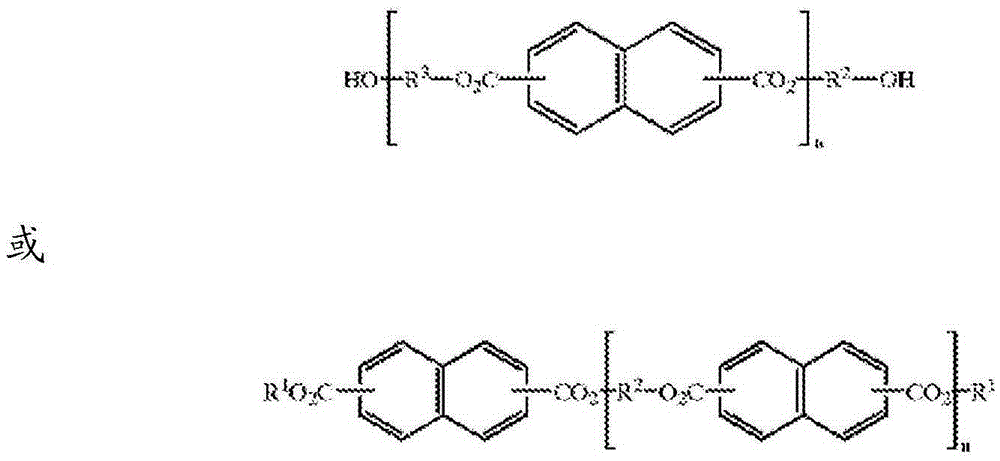

[0073] A preferred thickener for use in the present invention is an acrylate crosslinked silicone copolymer network (sometimes referred to as a "polyacrylate siloxane copolymer network") and its preparation is fully disclosed in 2008 In US Patent Publication 2008 / 0051497A1, Lu et al., published February 28, 2008. These copolymers contain the following reaction products:

[0074] a) M a m H b-h-k m PE h m E k D. c D. H d-i-l D. PE i D. E l TeT H f-j-m T PE j T E m Q g and

[0075] b) acrylates in stoichiometric or superstoichiometric amounts, wherein:

[0076] M=R 1 R 2 R 3 SiO 1 / 2 ;

[0077] m H =R 4 R 5 HSio 1 / 2 ;

[0078] m PE =R 4 R 5 (--

[0079] CH 2 CH(R 9 )(R 10 ) n O(R 11 ) o (C 2 h 4 O) p (C 3 h 6 O) q (C 4 h 8 O) r R 12 ) SiO 1 / 2 ;

[0080] m E =R 4 R 5 (--R 17 R 18 C--CR 16 Q s Q t R 15 (COC)R 13 R 14 ) SiO 1 / 2

[0081] D=R 6 R 7 SiO 2 / 2 ;and

[0082] D. H =R 8 HSio 2 / 2

[0083] D. PE =R 8 ...

example

[0157] The following are examples of compositions comprising UV actives.

[0158] sunscreen composition

[0159] The following are examples of sunscreen compositions using a combination of UV actives and stabilizers. Solastay S1 (ethylhexylmethoxycrine) from Hallstar is exemplified as a preferred stabilizer according to the invention. Also exemplified are superabsorbent polymers and silicone elastomers. The in vivo SPF for the examples below ranges from as low as 15 to over 50 SPF. The compositions in Examples 1 to 15 were prepared as follows. In a suitable vessel, combine the water phase ingredients and heat to 75°C. In a separate suitable vessel, the oil phase ingredients were combined and heated to 75°C. The oil phase is then added to the water phase, and the resulting emulsion is milled (eg, using rotor-stator milling). The thickener was then added to the emulsion, and while stirring, the emulsion was cooled to 45°C. At 45°C, the remaining additional ingredients w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com