Sun-screening composition and preparation method and application thereof

A technology for a composition and a sunscreen agent, applied in the field of sunscreen compositions and their preparation, can solve the problems of unfavorable use of sunscreen products, economical production, increased amount of sunscreen paste, heavy processes, etc., so as to improve the flexibility of formulation combination and reduce grease the effect of increasing the sun protection factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

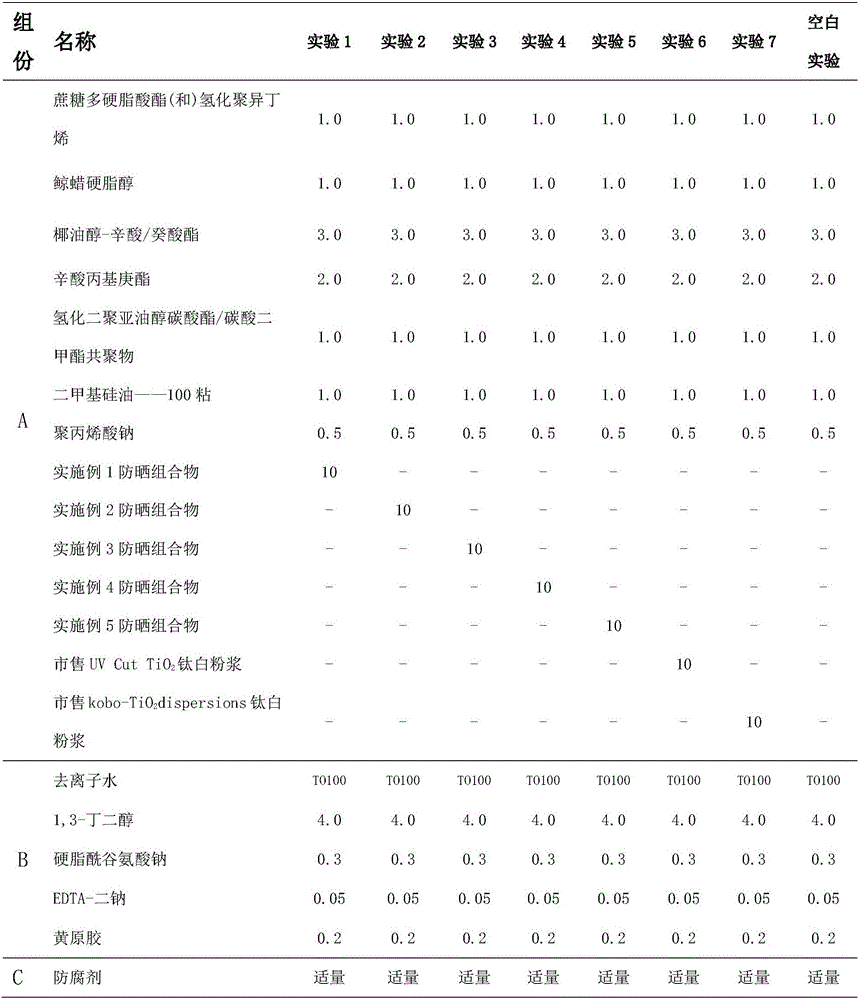

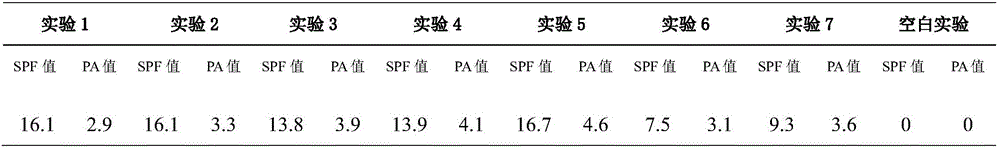

Examples

Embodiment 1

[0040] The sunscreen composition of the present embodiment is made up of the raw material of following weight:

[0041] 30g of nano-titanium dioxide, 67g of isoamyl p-methoxycinnamate, and 3g of polyhydroxystearic acid, wherein the diameter of nano-titanium dioxide is 10nm-100nm.

[0042] The preparation method of above-mentioned sunscreen composition is as follows:

[0043] Weigh 30g of nano-titanium dioxide, 67g of p-methoxyisoamyl cinnamate, and 3g of polyhydroxystearic acid, and put the weighed nanometers of p-methoxyisoamyl cinnamate and polyhydroxystearic acid into the reactor Stir evenly to obtain the first mixture; then evacuate the reactor to -0.1Mpa, and at the same time, pump the above-mentioned weighed nano-titanium dioxide into the reactor from the bottom of the reactor while vacuuming, keep the reactor in a vacuum state, and then stir Until the titanium dioxide is completely wet; then, continue to stir homogeneously in the high-pressure mode of the reactor; afte...

Embodiment 2

[0045] The sunscreen composition of the present embodiment is made up of the raw material of following weight:

[0046] 40g of nano-titanium dioxide, 52g of hexyl methoxycinnamate, and 8g of polyglyceryl polysiloxane, wherein the diameter of nano-titanium dioxide is 20nm-80nm.

[0047] The preparation method of above-mentioned sunscreen composition is as follows:

[0048] Weigh 40g of nano-titanium dioxide, 52g of hexyl methoxycinnamate, and 8g of polyglyceryl polysiloxane, put the weighed hexyl methoxycinnamate and polyglyceryl polysiloxane into the reactor and stir Evenly, the first mixture is obtained; then the reactor is evacuated to -0.2Mpa, and at the same time, the above-mentioned weighed nano-titanium dioxide is drawn into the reactor from the bottom of the reactor while vacuumizing, and the reactor is kept in a vacuum state, and then stirred until Titanium dioxide is in a completely wet state; then, continue to stir homogeneously in the high-pressure mode of the reac...

Embodiment 3

[0050] The sunscreen composition of the present embodiment is made up of the raw material of following weight:

[0051] 55g of nano-titanium dioxide, 20g of ethylhexyl salicylate, and 15g of decyl glucoside, wherein the diameter of nano-titanium dioxide is 50nm-100nm.

[0052] The preparation method of above-mentioned sunscreen composition is as follows:

[0053]Weigh 55g of nano-titanium dioxide, 20g of ethylhexyl salicylate, and 15g of decyl glucoside, put the weighed ethylhexyl salicylate and decyl glucoside into the reactor and stir evenly to obtain the first mixture; Then the reactor is evacuated to -0.2Mpa, while the above-mentioned weighed nano-titanium dioxide is drawn into the reactor from the bottom of the reactor while vacuumizing, and the vacuum state of the reactor is kept, and then stirred until the titanium dioxide is completely wetted; Continue to stir homogeneously in the high-pressure mode of the reactor; after the stirring is completed, take a sample to det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com