Fuel injection valve

A fuel injection valve, fuel injection technology, applied in the direction of fuel injection device, low-pressure fuel injection, charging system, etc., to achieve the effect of suppressing change, design or design change easily

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

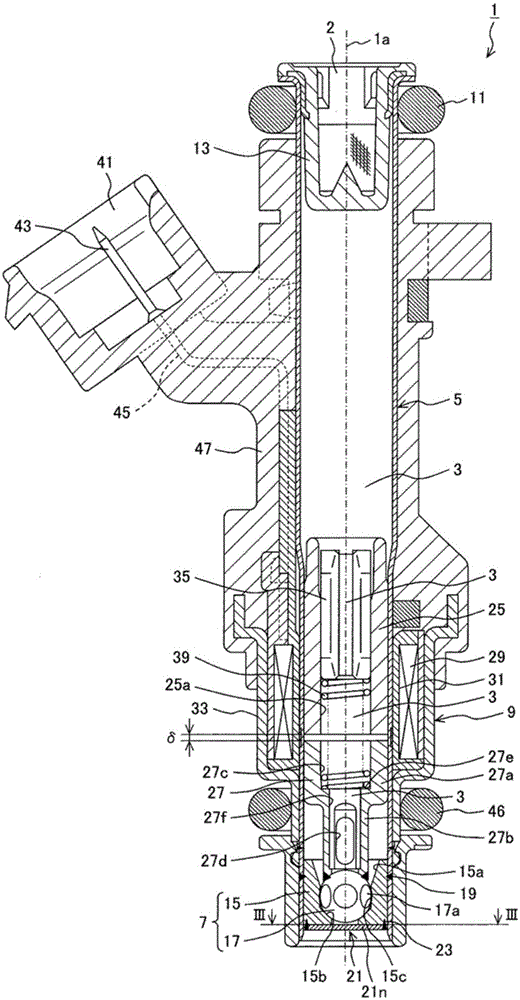

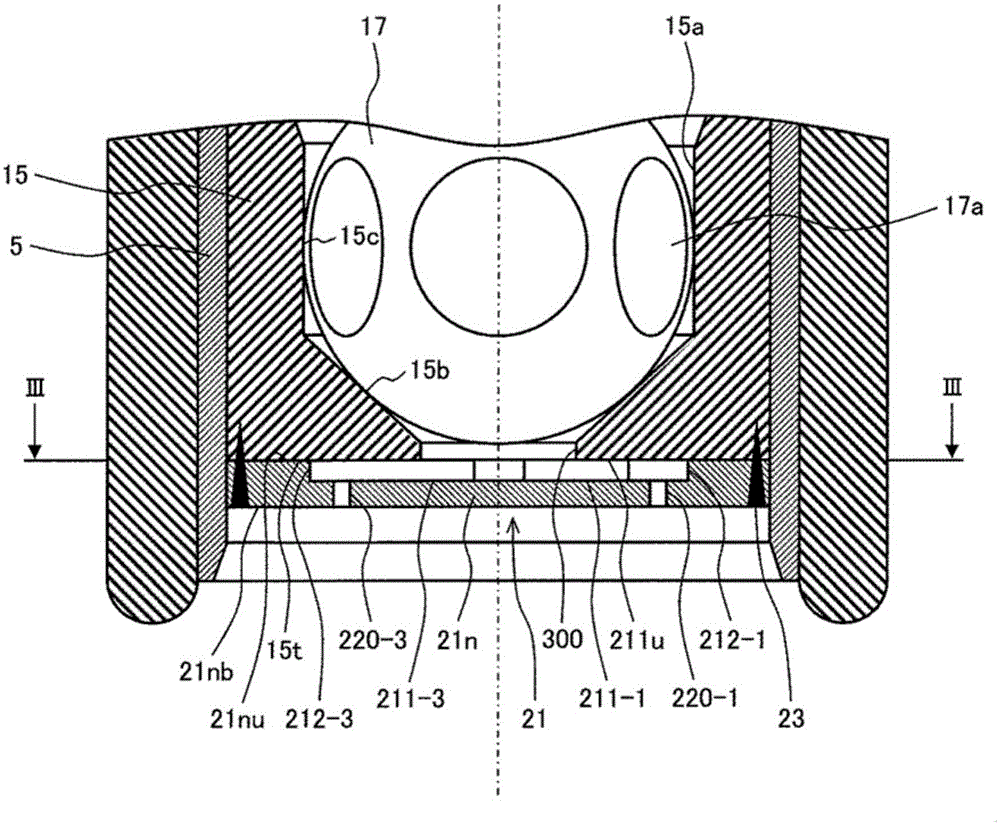

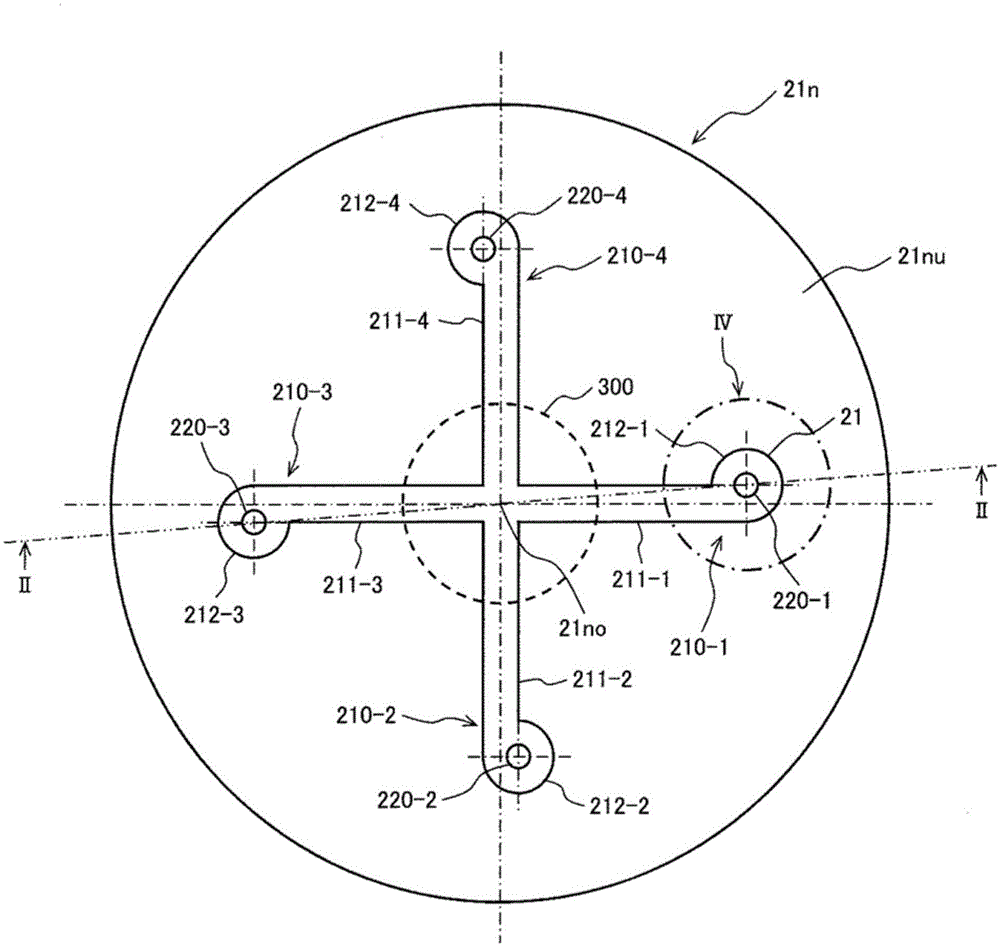

[0091] use Figure 1 to Figure 8 Examples of the present invention will be described.

[0092] use figure 1 The overall structure of the fuel injection valve 1 will be described. figure 1 It is a longitudinal sectional view showing a section along the central axis 1 a of the fuel injection valve 1 of the present embodiment. The central axis 1 a coincides with the axis (valve axis) of the mover 27 integrally provided with the valve body 17 described later, and coincides with the central axis of the cylindrical body 5 described later. In addition, the center axis line 1a also coincides with the center line of the valve seat 15b described later.

[0093] The fuel injection valve 1 is provided with a cylindrical body 5 made of a metal material extending from an upper end to a lower end. Inside the cylindrical body 5, the fuel flow path 3 is formed substantially along the central axis 1a. exist figure 1 In , the upper end portion (upper end side) is referred to as the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com