Multi-piece combined inner core supported on automobile shock absorber

An automobile shock absorber and multi-piece combination technology, which is applied in the field of automobile parts manufacturing, can solve problems such as performance limitations and manufacturing difficulties, and achieve the effects of high product consistency, improved performance, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

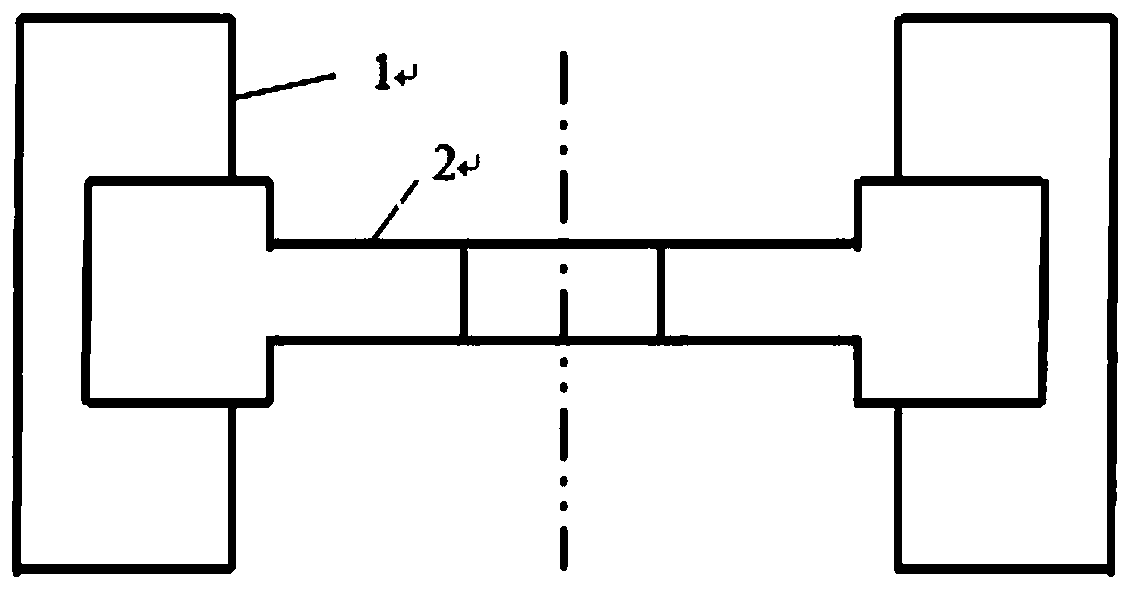

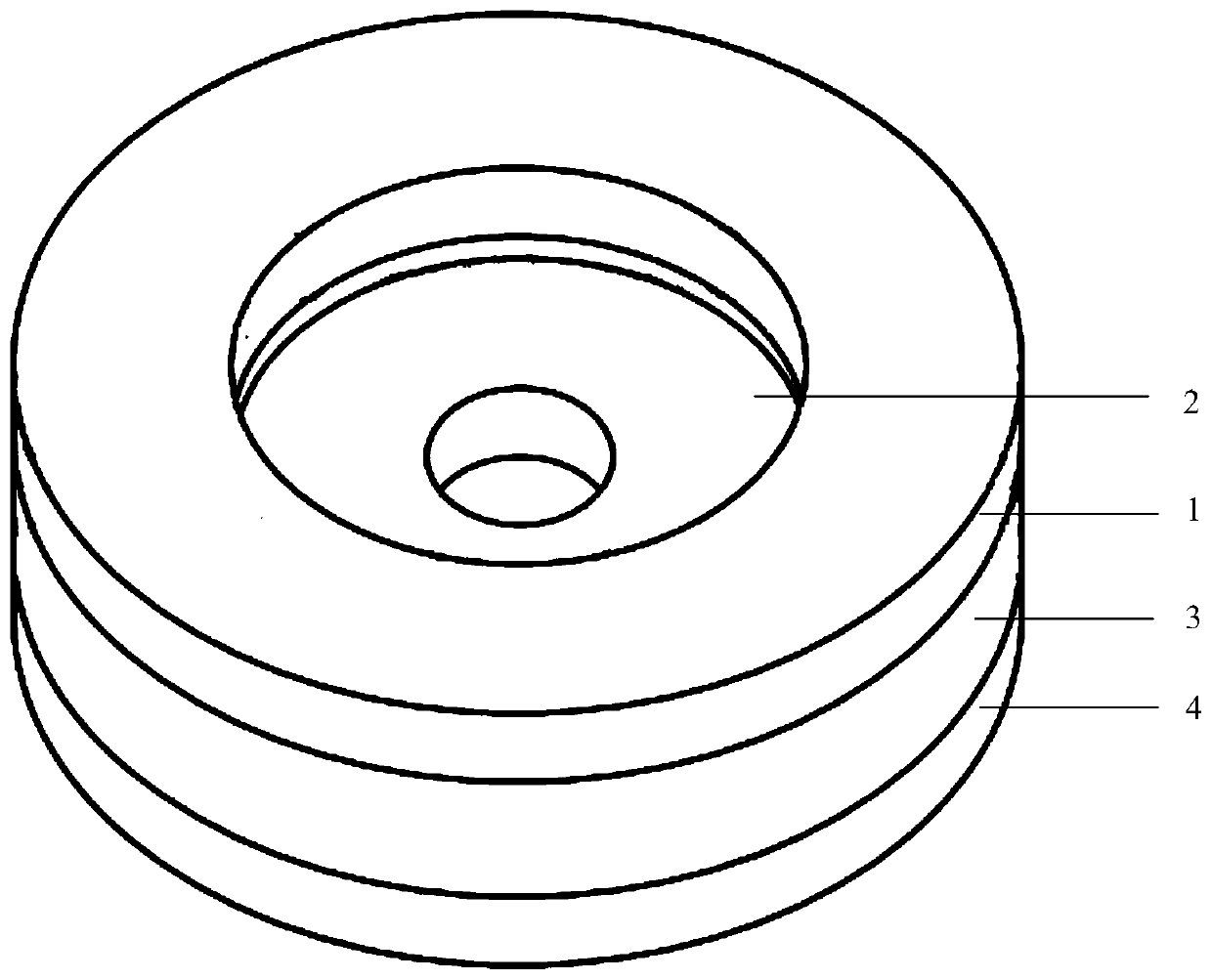

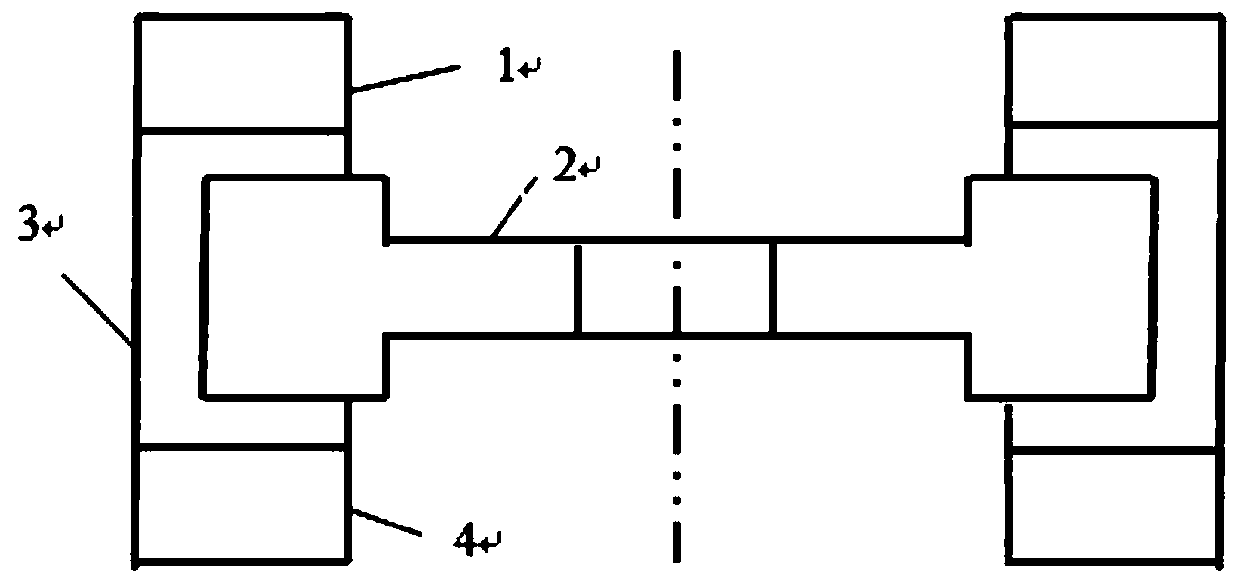

[0041] An embodiment of the present invention provides a multi-piece combined inner core supported on an automobile shock absorber, including: a partition plate 2 and a vibration isolation element, the vibration isolation element surrounds the edge of the partition plate 2 for a week, and the isolation plate The edge of the plate 2 is embedded in the central groove of the vibration isolation element; the vibration isolation element includes: an upper vibration isolation block 1, an inner adhesive layer 3, and a lower vibration isolation block 4; the inner adhesive layer 3 The partition plate 2, the upper vibration isolation block 1, and the lower vibration isolation block 4 are bonded as a whole; wherein the partition plate 2 is made of metal material, the upper vibration isolation block 1, and the inner bonding Layer 3 and the lower vibration-isolating block 4 are both made of polymer elastomer.

[0042] In this embodiment, the inner adhesive layer 3 is made of rubber, and th...

Embodiment 2

[0049] The structural configuration of this embodiment is the same as that of the first embodiment, the difference is that the inner adhesive layer 3 is made of thermoplastic polyurethane, and is combined with the partition plate 2 through an injection process to become a component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com