LED illuminating device and manufacturing method thereof

A technology of LED lighting and LED chips, which is applied to lighting devices, components of lighting devices, lighting and heating equipment, etc. It can solve the problems of lack of advantages in LED chip bonding and welding processes, high mass production costs, and low process reliability. problems, to achieve the effect of reducing the amount of deformation, using less metal materials, and improving the manufacturing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

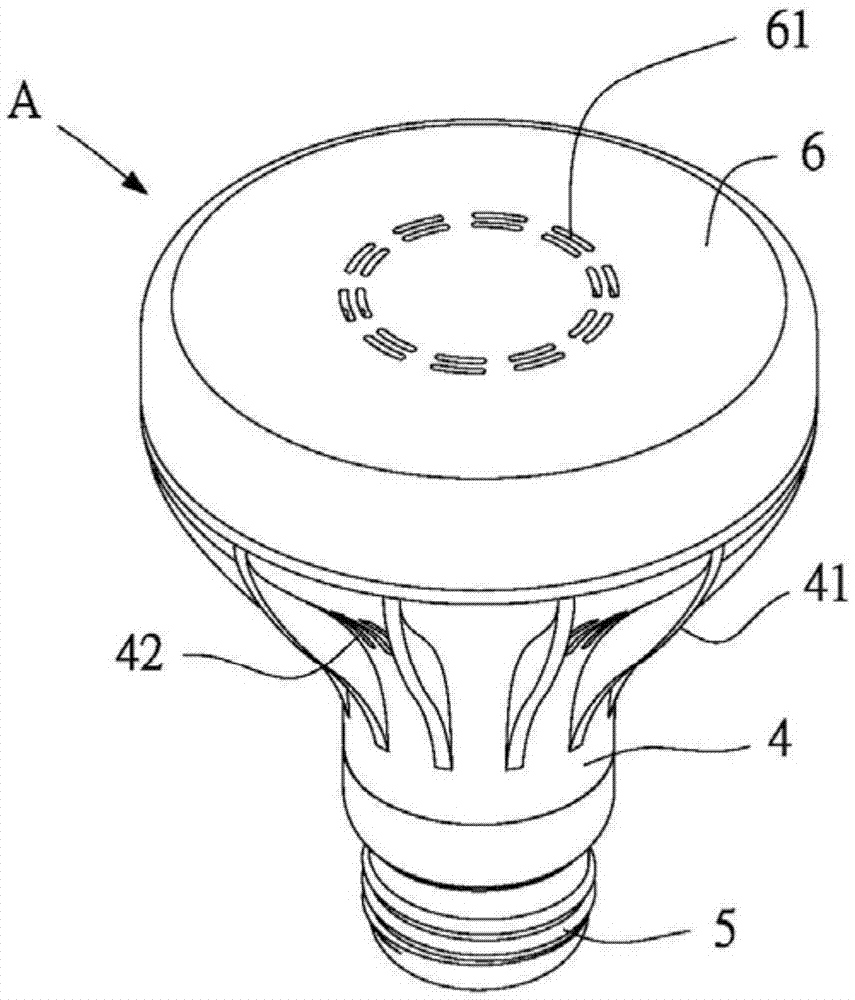

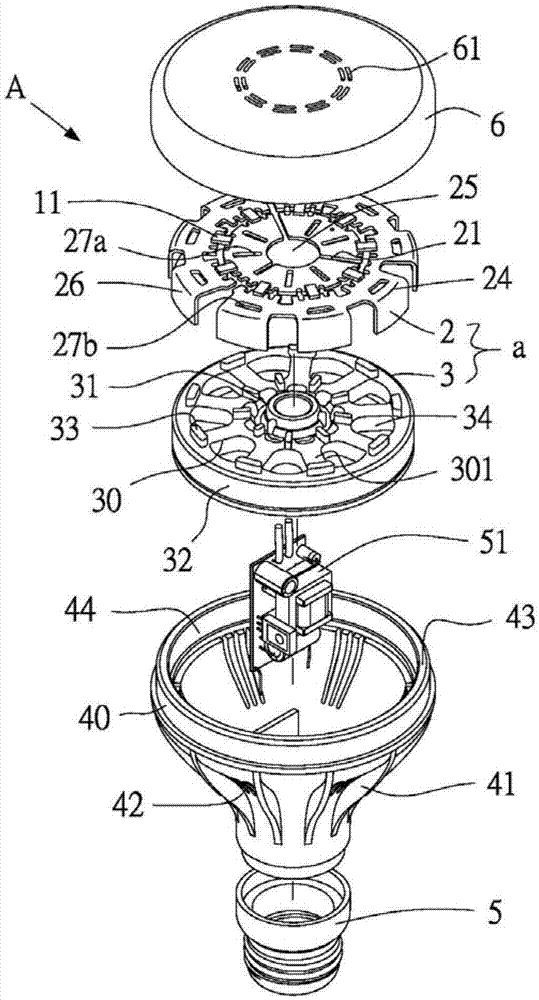

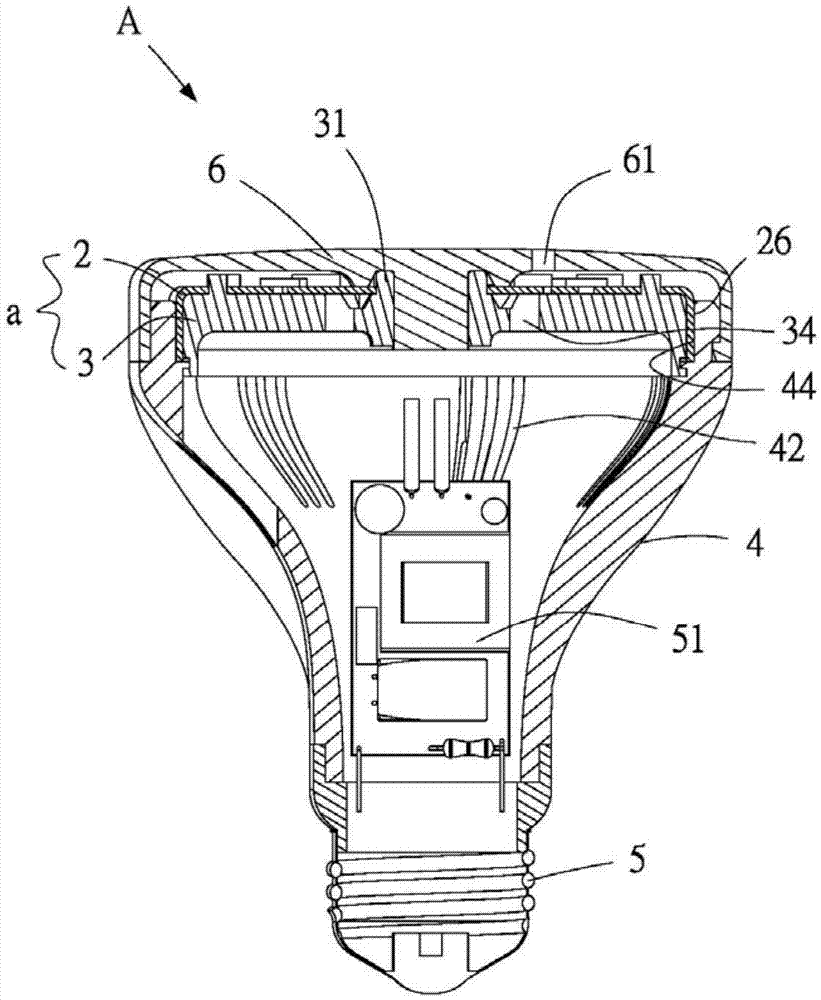

[0136] The present invention relates to an LED lighting device and a manufacturing method thereof, together with seven embodiments and seven sets of system drawings, to illustrate the core technology used in the present invention. In other words, where Figure 1 ~ Figure 1i , is the lighting device of the flat bulb lamp and the manufacturing method thereof according to the first embodiment of the present invention; Figure 2 ~ Figure 2h , about the lighting device of the curved bulb lamp according to the second embodiment of the present invention, and so on. In particular, the main components of the structure of each embodiment of the present invention, and components with the same function are summed up with one component symbol to simplify the description of the present invention.

[0137] see Figure 1e , the lighting device of each embodiment of the present invention is mainly composed of a conductive plate 2 combined with a support frame 3; wherein the conductive plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com