Purification device and method of purifying modified ilmenite concentrate with purification device

An ilmenite concentrate and modification technology, which is applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of high particle size requirement, poor adaptability, difficult operation and control of modified ilmenite concentrate, and achieve a simple structure. , The effect of easy industrial amplification and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] a. Preparation of modified titanium concentrate

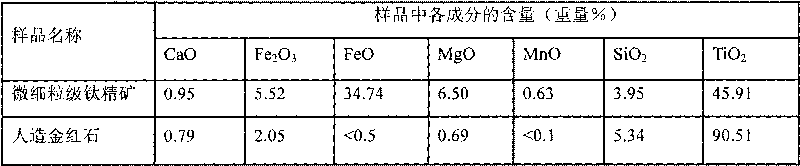

[0045] Oxidation Roasting: Take 2100 kg of fine-grained titanium concentrate (purchased from Panzhihua Iron and Steel Group’s fine-grained titanium concentrate (20# ore), see Table 1 for chemical composition analysis, and see Table 2 for particle size analysis), and first heat it at 650 ° C. After preheating in the preheater, enter the fluidized oxidation furnace (that is, the fluidized bed reactor during oxidation, including the separation section, the settling section and the reaction section interconnected from top to bottom) for oxidation roasting, wherein, The titanium concentrate enters the reaction section from the feed pipe at the bottom of the fluidized bed reactor, the air enters the reaction section from the reaction gas inlet at the bottom of the fluidized oxidation furnace, and the oxidized roasted product enters the reaction section from the fluidized oxidation furnace. The output pipe of the settling secti...

Embodiment 2

[0058] Adopt the method described in embodiment 1 to prepare artificial rutile, the difference is,

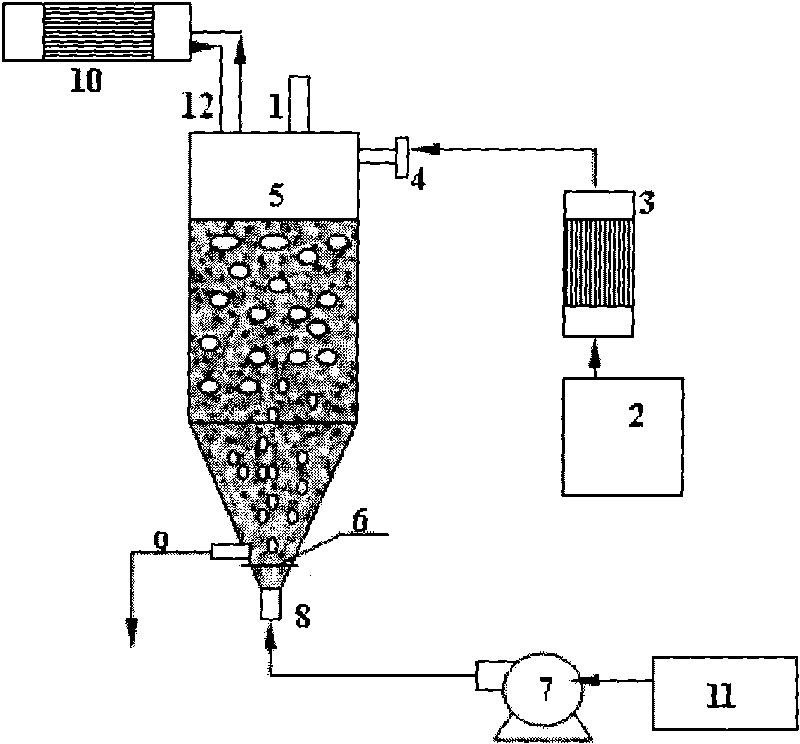

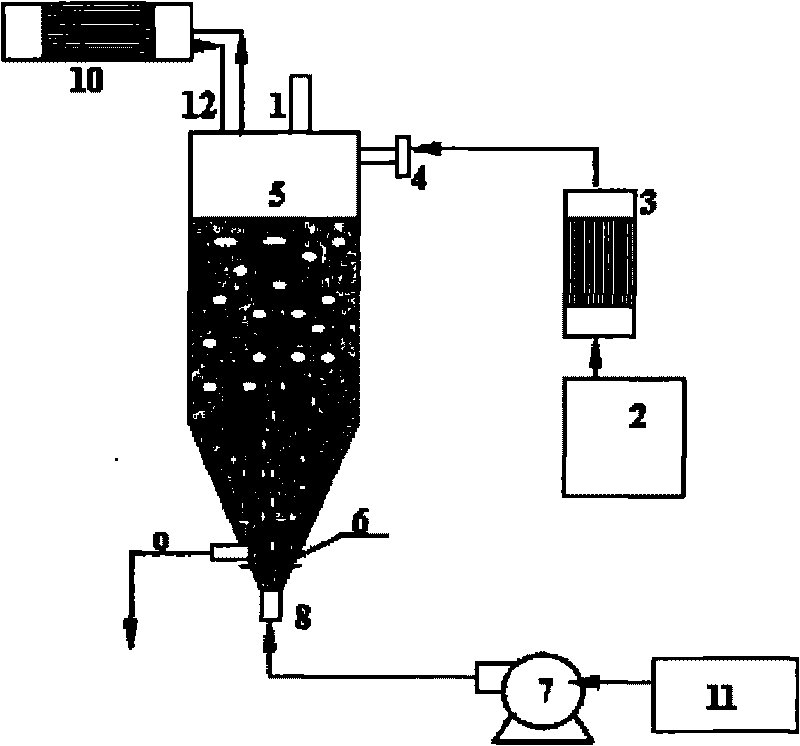

[0059] In step b, such as figure 1 As shown, 1000 kilograms of magnetically modified titanium concentrate after pre-magnetic separation are fed into the reactor (5) from the second opening (1), and the storage tank (2) is passed through the third opening (4) through the third opening (4). Two heaters (3) are heated to 50 DEG C concentration and be that the hydrochloric acid of 35% by weight is supplied in the reactor (5), and described reactor (5) comprises two sections up and down, and the upper section is cylindrical, and the lower section is inverted conical, The height ratio of the upper section and the lower section is 2: 1, and the cone angle of the inverted cone is 40 degrees; the feed rate of hydrochloric acid is 200 liters / minute, and it is fed into the reactor (5) from the fourth opening (8). ) under the agitation and heating of the 100°C hot air flow in the reactor ...

Embodiment 3

[0062] Adopt the method described in embodiment 1 to prepare artificial rutile, the difference is,

[0063] In step a, 2100 kg of coarse-grained titanium concentrate is used as raw material (purchased from Pangang Group coarse-grained titanium concentrate (10# ore));

[0064] Moreover, in step b, if figure 1As shown, 2000 kilograms of magnetically modified titanium concentrate after pre-magnetic separation are fed into the reactor (5) from the second opening (1), and the storage tank (2) from the storage tank (2) is passed through the third opening (4) through the third opening (4). Two heater (3) is heated to the concentration of 80 ℃ and is that the hydrochloric acid of 25% by weight is supplied in the reactor (5), and described reactor (5) comprises two sections up and down, and the upper section is cylindrical, and the lower section is inverted conical, The height ratio of the upper section and the lower section is 4: 1, and the cone angle of the inverted cone is 50 degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com