Special nylon worm gear for electric power steering (EPS) of automobile and preparation method thereof

An electric power steering, nylon technology, applied in the field of polymer nylon materials, can solve the problems of poor wear resistance, easy corrosion, high noise, etc., to achieve the effect of protecting the abrasive parts, ensuring the rotational strength and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

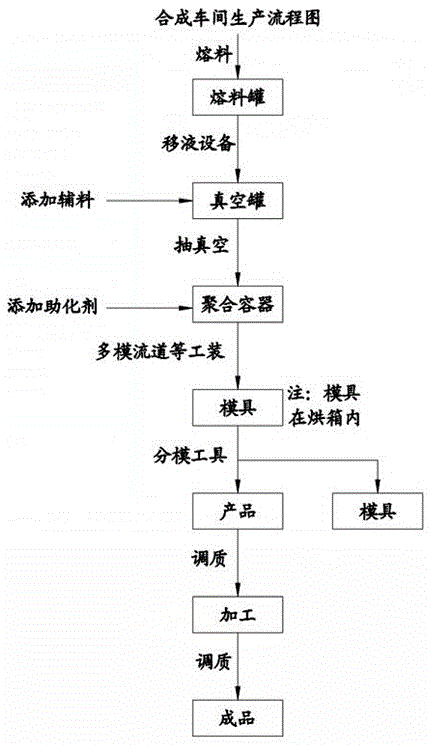

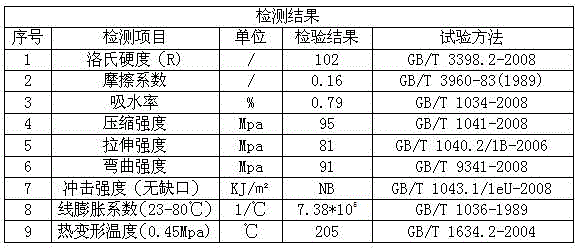

[0034] Such as figure 1 As shown, first, the inner iron core of the worm gear is cleaned and descaled with an ultrasonic cleaner, and then soaked in 35% methane coupling agent KH550 for 8 minutes. Put the soaked iron core and the mold together into a drying oven for preheating, the preheating temperature is 160°C, the iron core preheating time is 4 hours, and the worm wheel mold preheating time is 2 hours. The nylon raw material is melted, and the melting temperature must not exceed 140°C. Select 99.22% of nylon raw material, 0.2% of catalyst, 0.28% of chemical aid, 0.025% of nylon oil, 0.25% of modifier, and 0.025% of toner. In the storage tank, stir evenly. Connect the vacuum device and carry out vacuum extraction on it. The vacuum device connects the vacuum tube from the storage tank to the calcium chloride reactor, and then connects the calcium oxide reactor to the 2X-15 rotary vane vacuum pump. The vacuuming time is 8 minutes, the vacuum degree is -0.1 Pa, and the tem...

Embodiment 2

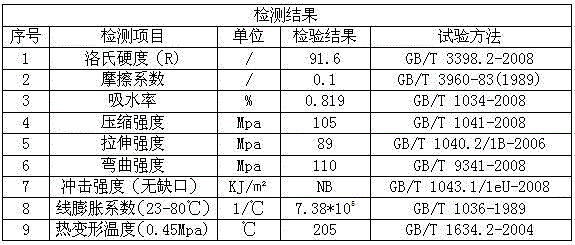

[0040] Such as figure 1As shown, first, the inner iron core of the worm gear is cleaned and descaled with an ultrasonic cleaner, and then soaked in methane coupling agent KH550 with a concentration of 35% for 9 minutes. Put the soaked iron core and the mold together into a drying oven for preheating, the preheating temperature is 160°C, the iron core preheating time is 4 hours, and the worm wheel mold preheating time is 2 hours. The nylon raw material is melted, and the melting temperature must not exceed 140°C. Select 99.45% nylon raw material, 0.3% catalyst, 0.35% chemical aid, 0.03% nylon oil, 0.3% modifier, and 0.03% toner. In the storage tank, stir evenly. Connect the vacuum device and carry out vacuum extraction on it. The vacuum device connects the vacuum tube from the storage tank to the calcium chloride reactor, and then connects the calcium oxide reactor to the 2X-15 rotary vane vacuum pump. The vacuuming time is 9 minutes, the vacuum degree is -0.1 Pa, and the t...

Embodiment 3

[0046] Such as figure 1 As shown, firstly, the inner iron core of the worm gear is cleaned and descaled with an ultrasonic cleaner, and then soaked in 35% methane coupling agent KH550 for 10 minutes. Put the soaked iron core and the mold together into a drying oven for preheating, the preheating temperature is 165°C, the preheating time for the iron core is 4 hours, and the preheating time for the worm gear mold is 3 hours. The nylon raw material is melted, and the melting temperature must not exceed 140°C. Select 98.99% of nylon raw material, 0.1% of catalyst, 0.2% of chemical aid, 0.02% of nylon oil, 0.2% of modifier, and 0.02% of toner. In the storage tank, stir evenly. Connect the vacuum device and carry out vacuum extraction on it. The vacuum device connects the vacuum tube from the storage tank to the calcium chloride reactor, and then connects the calcium oxide reactor to the 2X-15 rotary vane vacuum pump. The vacuuming time is 10 minutes, the vacuum degree is -0.1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com