Reinforcing device for machining machinery base

A processing machine and reinforcement device technology, which is applied in the field of processing machine base reinforcement devices, can solve the problems that the base is easily damaged, easily tilted, and affects production efficiency, etc., and achieve the effects of enhanced support effect, effective support structure, and enhanced connection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

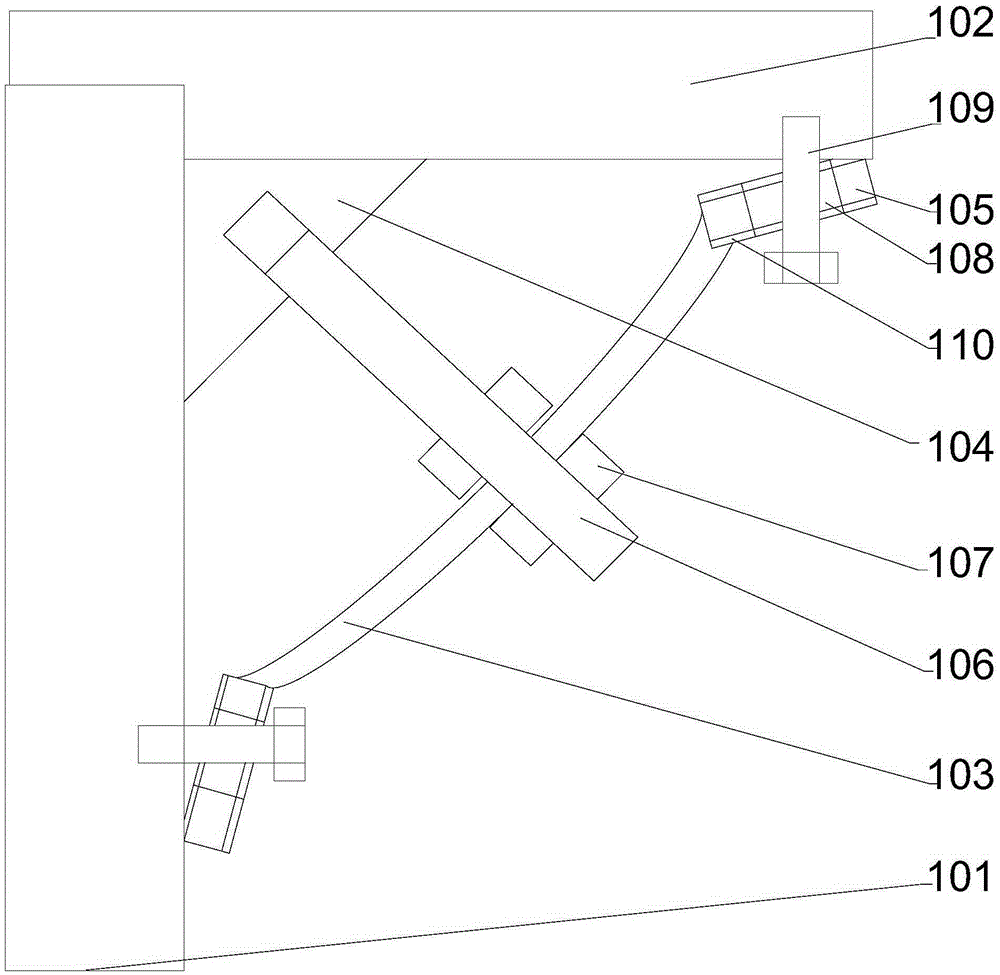

[0019] Such as figure 1 As shown, a processing machine base reinforcement device includes a base body 101 and a processing machine body 102 disposed above the base body 101, a support plate 103 is provided below the processing machine body 101, and the support plate 103 is Placed obliquely, the middle part of the support plate 103 is arched obliquely downward, a top angle part is formed between the base body 101 and the lower end surface of the processing machine body 102, and a pad is provided at the top foot part Block 104, the two right-angled sides of the pad 104 are attached to the lower end surface of the processing machine body 102 and the side wall of the base body 101 respectively, and the two ends of the support plate 103 are respectively A fixing plate 105 is provided, a through hole is provided in the middle of the support plate 103, a threaded hole is provided on the slope of the pad 104, and a stud 106 is provided in the through hole, and the One end of the stud...

Embodiment 2

[0023] This embodiment is based on Embodiment 1, in order to achieve a better fixing effect, in this embodiment, preferably, the end of the fixing plate 105 close to the supporting plate 103 points to the supporting plate 103 Central arch.

[0024] In order to achieve a better cushioning effect, in this embodiment, preferably, a rubber sheath 110 is fitted on the fixing plate 105 .

[0025] In order to enable the stud to better define the position and shape of the support plate, and at the same time enable the lock nut to better push the support plate, in this embodiment, preferably, two locks are arranged on the stud 106 Clamping nuts 107 , the two locking nuts 107 are respectively located on both sides of the support plate 103 . When adjusting, adjust the two lock nuts on the stud at the same time to realize the adjustment of the support plate.

[0026] In order to facilitate processing and make the structure more reliable, in this embodiment, preferably, the support plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com