A high-voltage excitation delay detonation control circuit

A control circuit, high-voltage charging technology, applied in blasting, electric fuze, weapon accessories and other directions, can solve the problems of difficult to guarantee accuracy, no circuit, reduce the reliability of network connection, etc., to achieve high delay accuracy and achieve safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

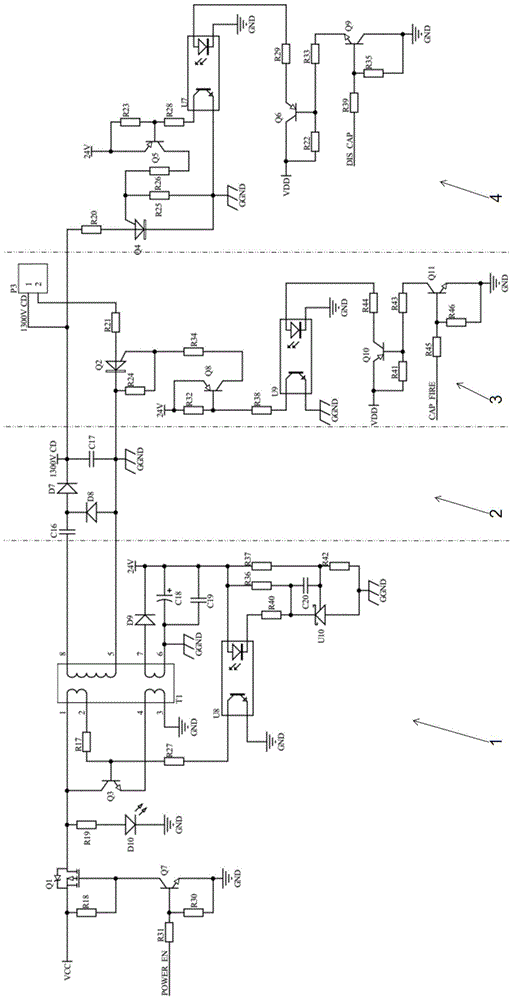

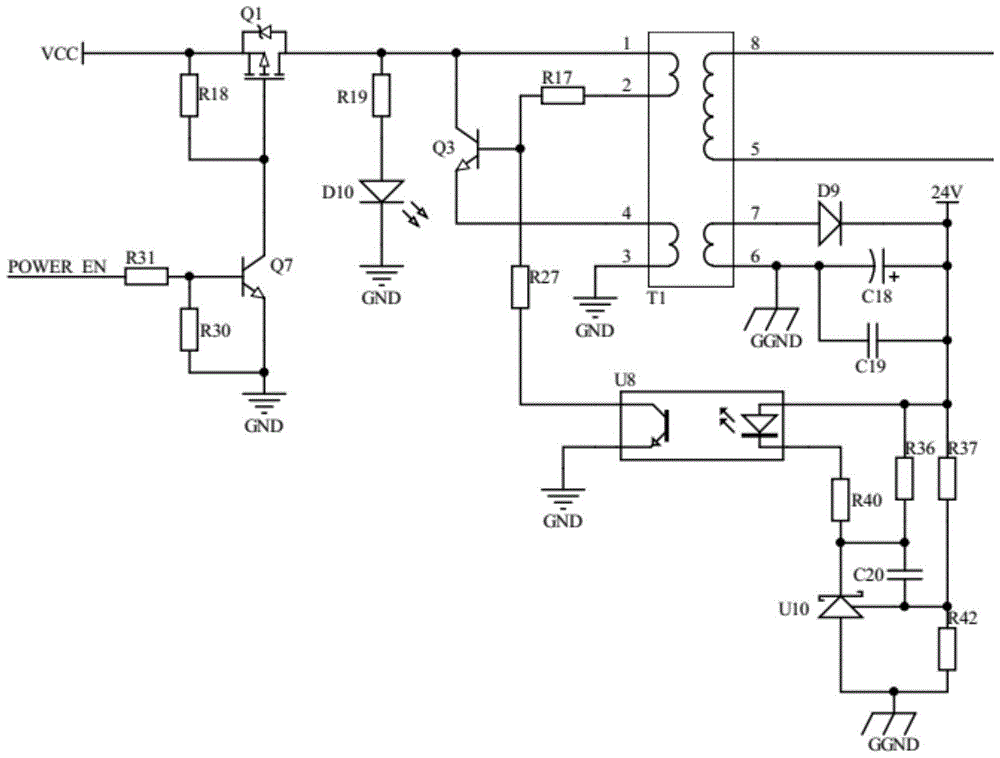

[0029] to combine figure 1 As shown, a high-voltage excitation delay detonation control circuit includes a boost circuit 1, a high-voltage charging circuit 2, a high-voltage discharging circuit 3, a protection circuit 4 and a functional circuit; wherein,

[0030] The boosting circuit 1 includes a transformer element T1; the boosting circuit is configured to receive an input low-voltage signal, and use the transformer element T1 to boost the low-voltage signal to a required high-voltage signal;

[0031] The high voltage in the present invention refers to a voltage greater than or equal to 1300V to meet the excitation requirements of the high-voltage excitation needle;

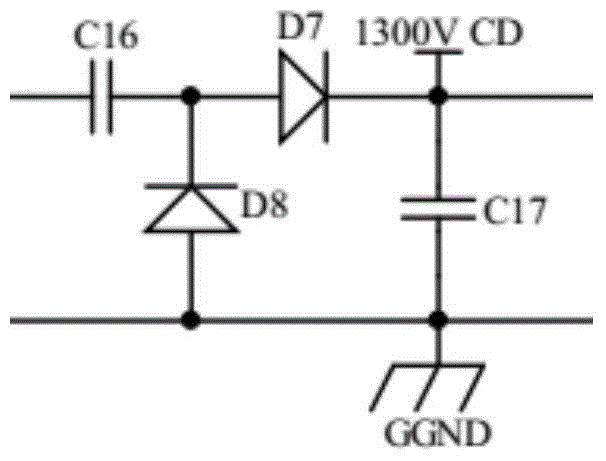

[0032] The high-voltage charging circuit 2 includes a high-voltage energy storage element; the high-voltage charging circuit is configured to receive the current input from the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com