Sliding plate bending die

A bending die and sliding plate technology, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of complex operation, low processing efficiency and high processing cost, and achieve the effect of simple operation and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

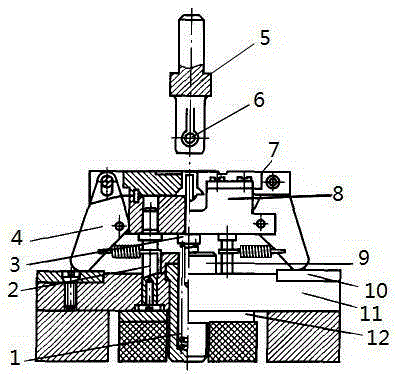

[0013] The reference signs in the drawings of the description include: compression spring 1, guide post 2, ejector rod 3, pendulum block 4, punch support 5, mandrel punch 6, forming slide block 7, die base frame 8, limit block 9. The first backing plate 10 , the base 11 , and the second backing plate 12 .

[0014] The embodiment is basically as attached figure 1 Shown: the skateboard bending die of this embodiment, the base 11 is placed on the upper part of the two supports, a rubber washer is arranged between the two supports, and a second backing plate 12 is arranged on the upper part of the rubber washer, and the second backing plate 12 is supported on The lower part of the base 11. A guide seat is installed on the rubber gasket and the second backing plate 12, a vertically movable push rod 3 is arranged in the guide seat, a flange is provided on the top of the push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com