A semi-automatic assembly method and equipment for a cosmetic cover

A semi-automatic, assembly method technology, applied in the field of cosmetic packaging, can solve labor and other problems, achieve the effects of precise operation process, reduced glue dosage, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solutions and advantages of the present invention more clear, the following will be described in detail in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

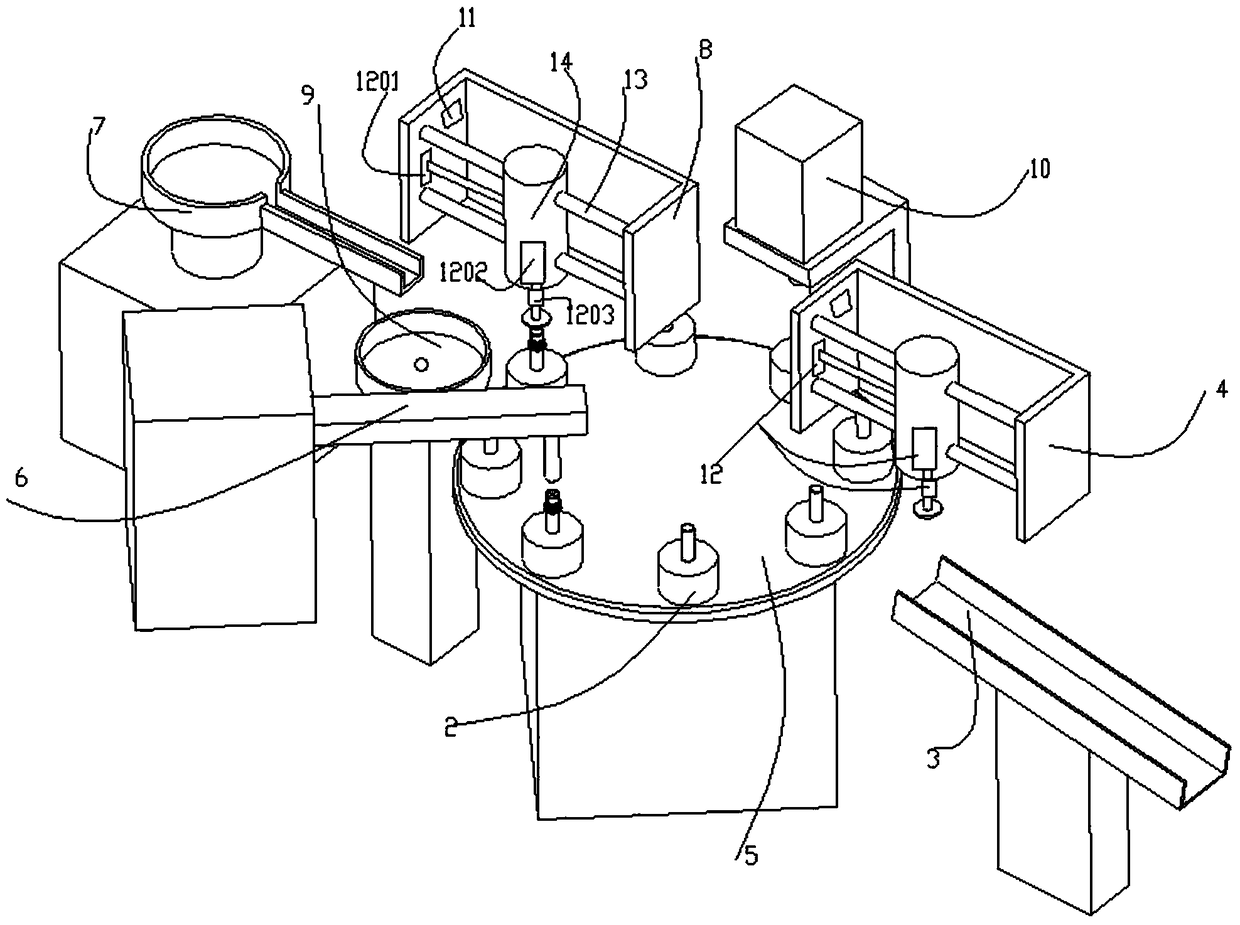

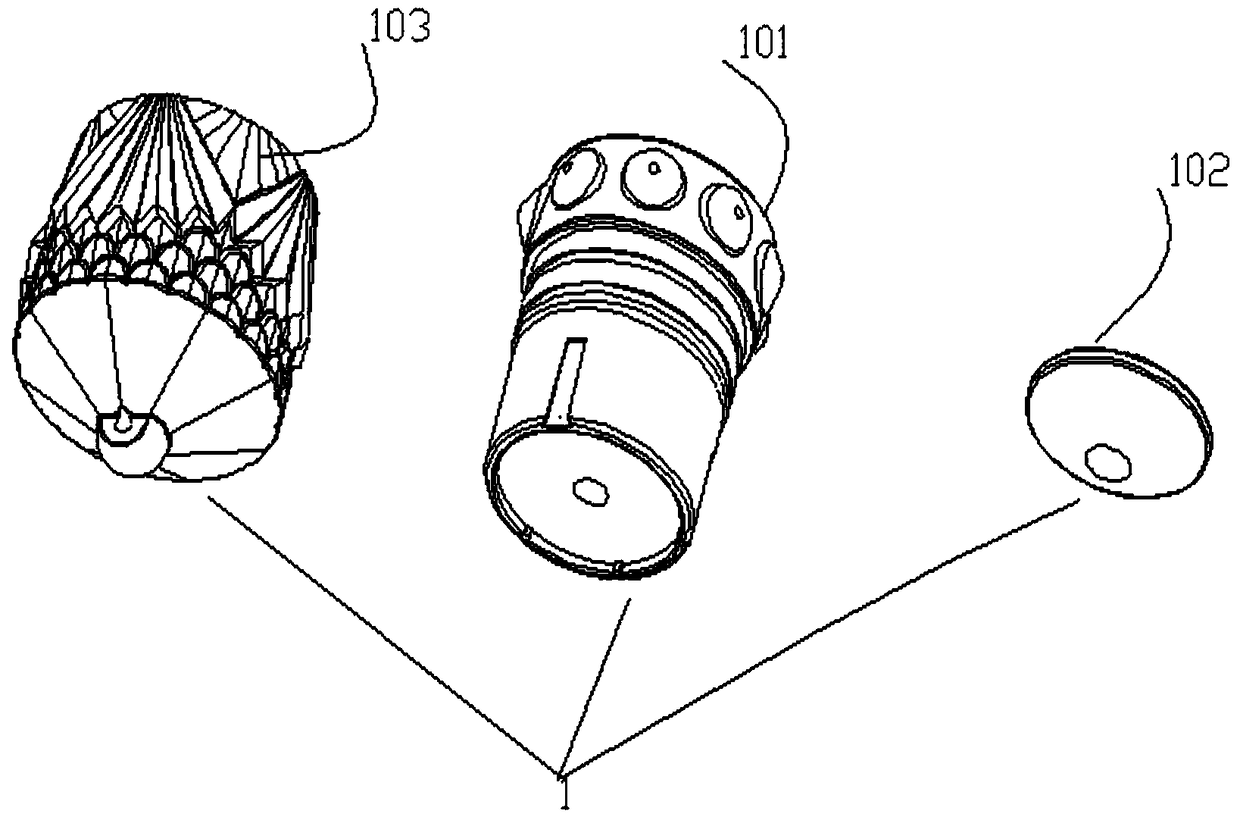

[0028] The cosmetic cover includes a top cover ring, a pendant on the upper surface of the top cover ring, and a top cover that matches the top cover ring, such as the cover body decoration of #14056~14057CL lipstick tube. The existing assembly technology basically uses manual However, there are problems such as low efficiency and poor product quality. Since the top cover and top cover ring of the cosmetic cover are all electroplated and bright, fully automated assembly production cannot be carried out, and there is no semi-automatic assembly method yet. .

[0029] This embodiment provides a semi-automatic method for assembling a cosmetic cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com