Highly-integrated modular robot joint

A robot joint, a highly integrated technology, applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of lack of market competitiveness of robot products, robot weight, size, and cost impact, so as to improve design efficiency, enhance competitiveness, joints, etc. The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

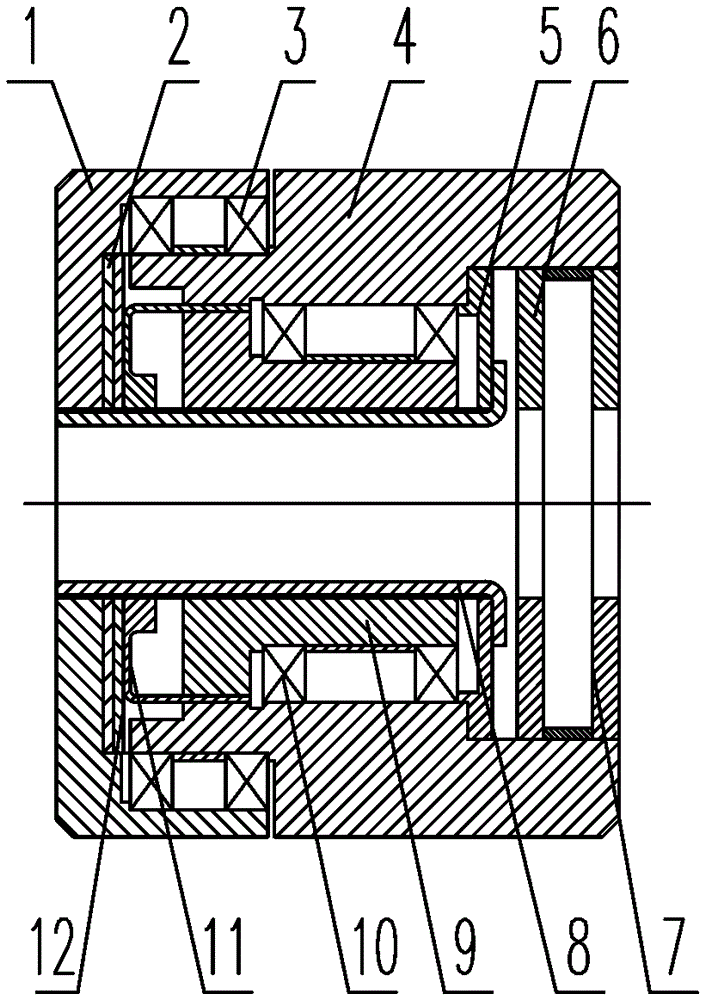

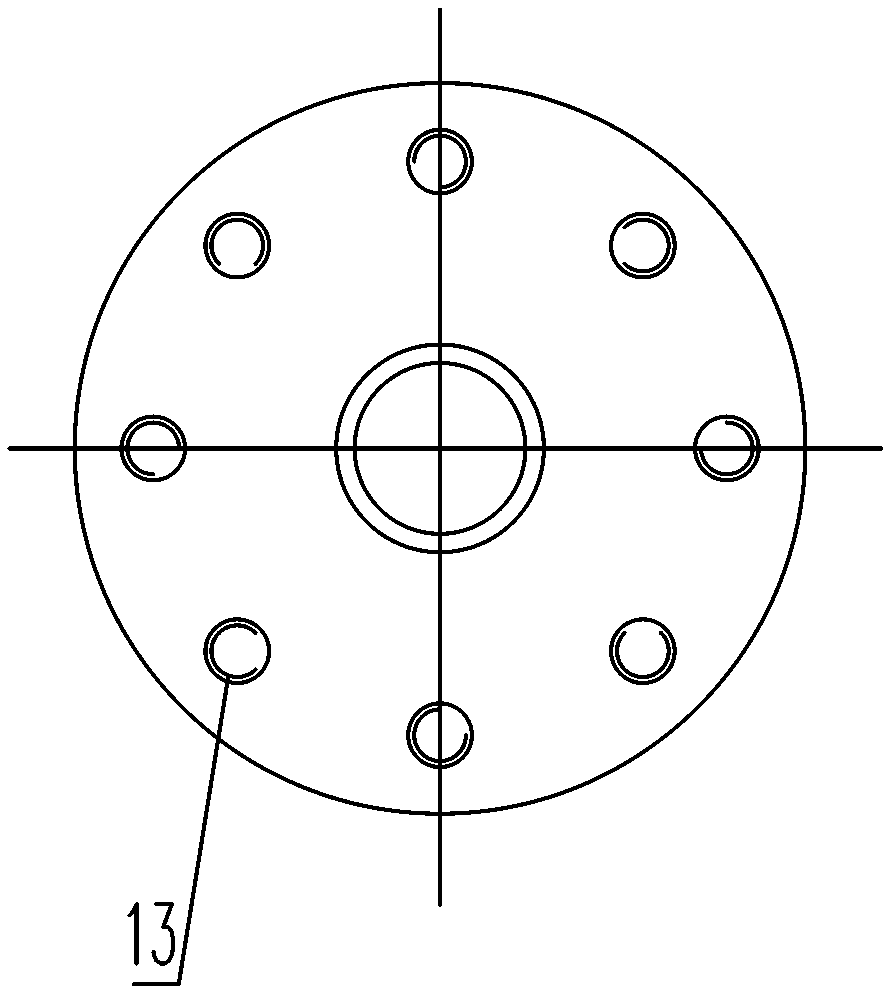

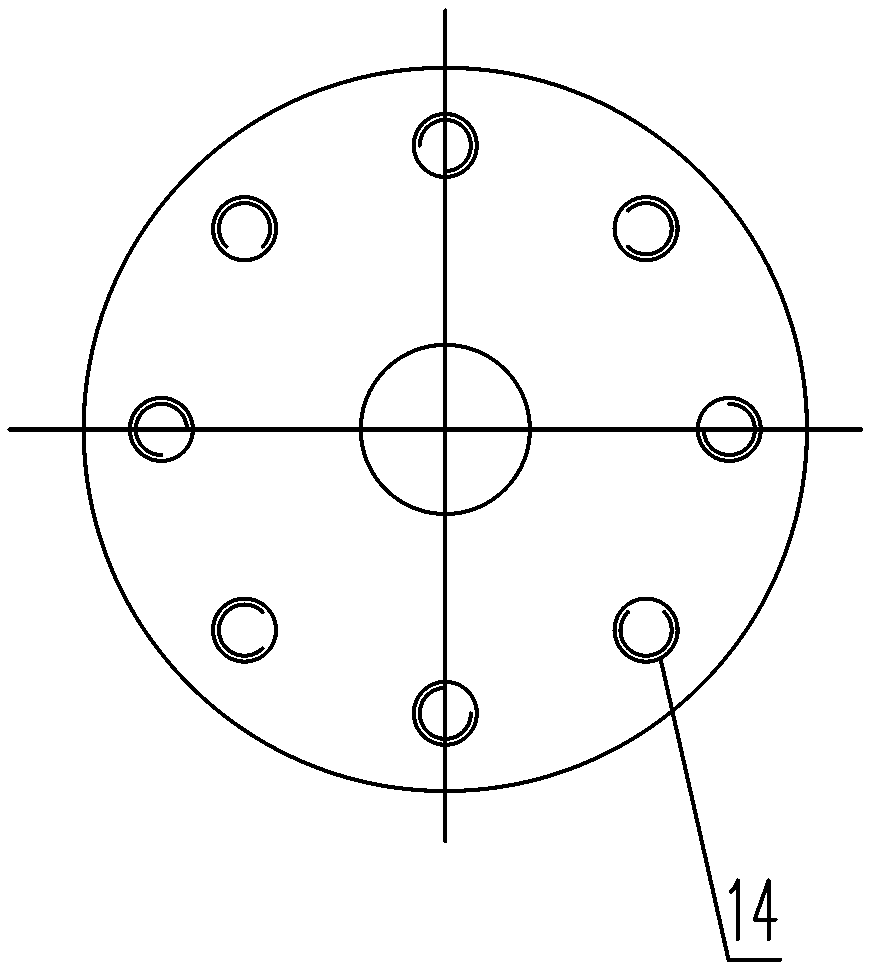

[0015] This embodiment provides a highly integrated modular robot joint, including a joint stator 4, and a pair of rotating bearings 3 on the outer ring of the joint stator 4, the joint output flange 1 is installed on the bearing 3, and the joint output flange 1 The torque sensor 2 and the position sensor 12 are installed on the inner side, and are fixedly connected with the output end of the flex spline 11. A pair of rotating bearings 10 are installed on the inner ring of the joint stator 4, and the joint rotor 9 is installed on the bearing 10. The joint rotor One end of 9 is designed with a wave generator, the wave generator is installed on the flexspline 11, the outer teeth of the flexspline 11 mesh with the inner teeth of the ring gear designed on the inner ring of the joint stator 4, the joint drive circuit board 6 and the joint control circuit boar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com