Body frame for motorcycles

A technology for motorized two-wheeled vehicles and car bodies, applied to motor vehicles, bicycle racks, bicycles, etc., can solve problems such as difficult alignment positions, and achieve the effect of easy joint operation and simple joint structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

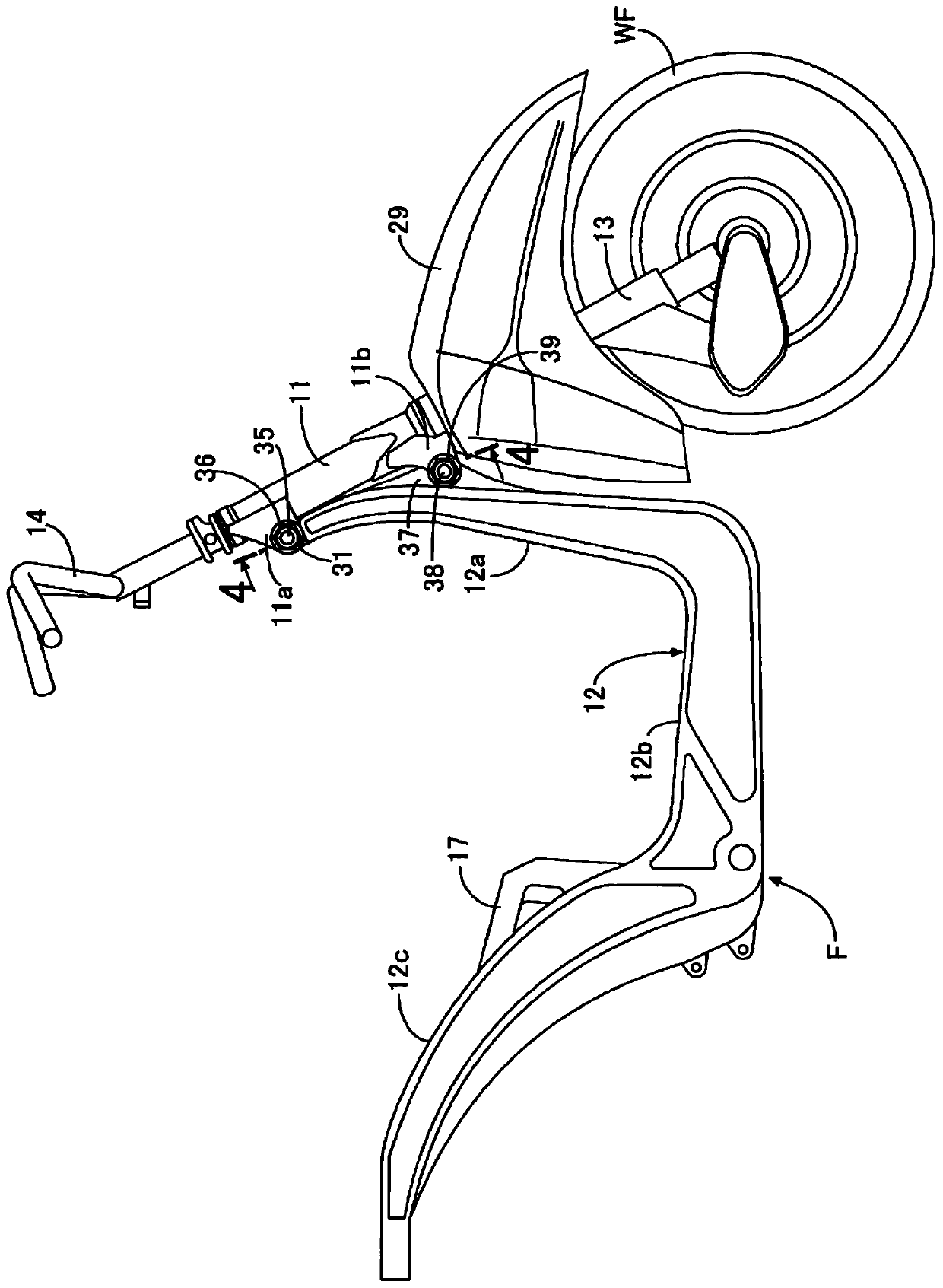

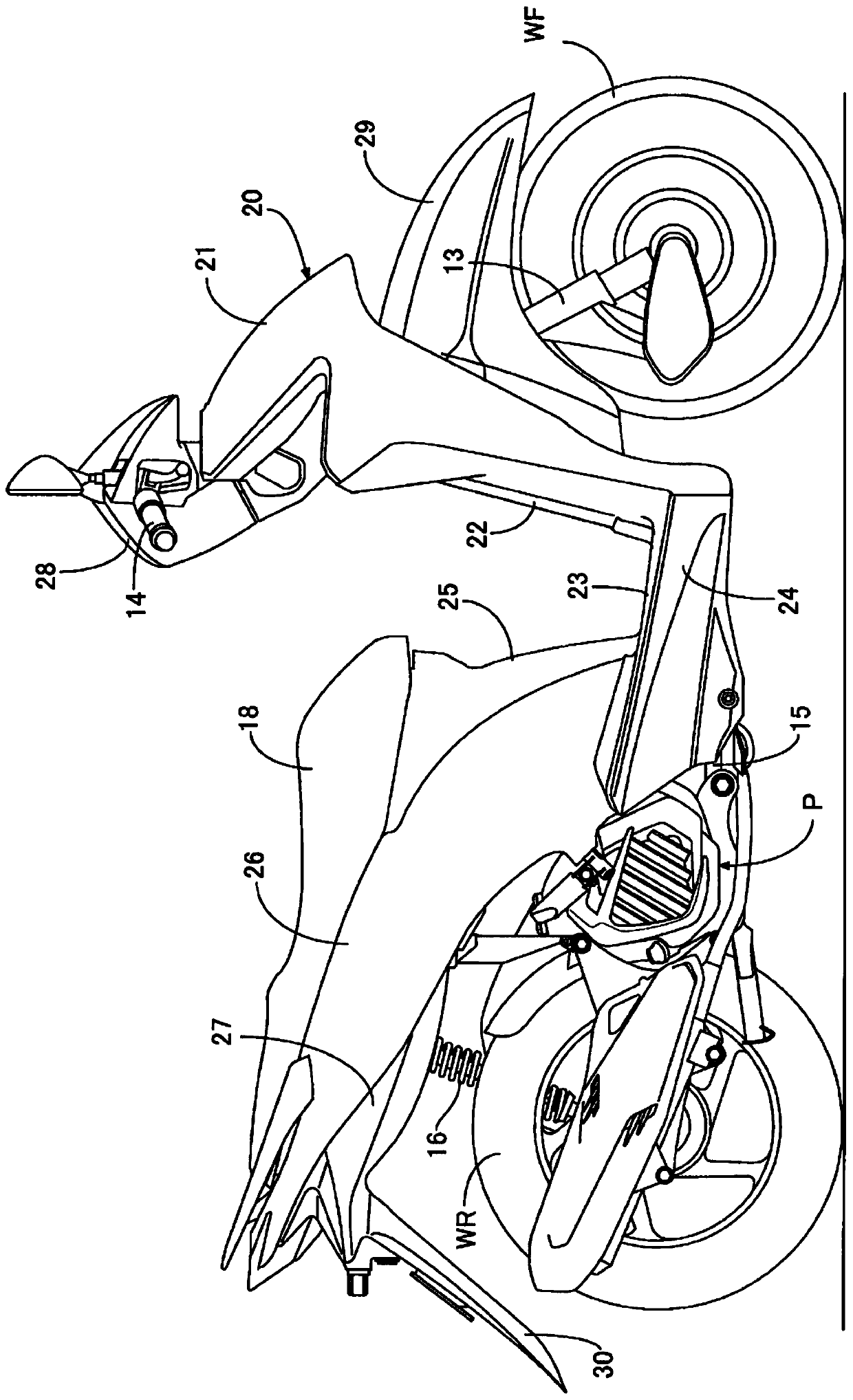

[0030] First, in figure 1 Among them, the body frame F of a small motorcycle has a head pipe 11 at its front end, a main frame 12 with a front end joined to the head pipe 11, a front fork 13 supporting a front wheel WF, and a bar-shaped steering handle. 14 is steerably supported on the head pipe 11.

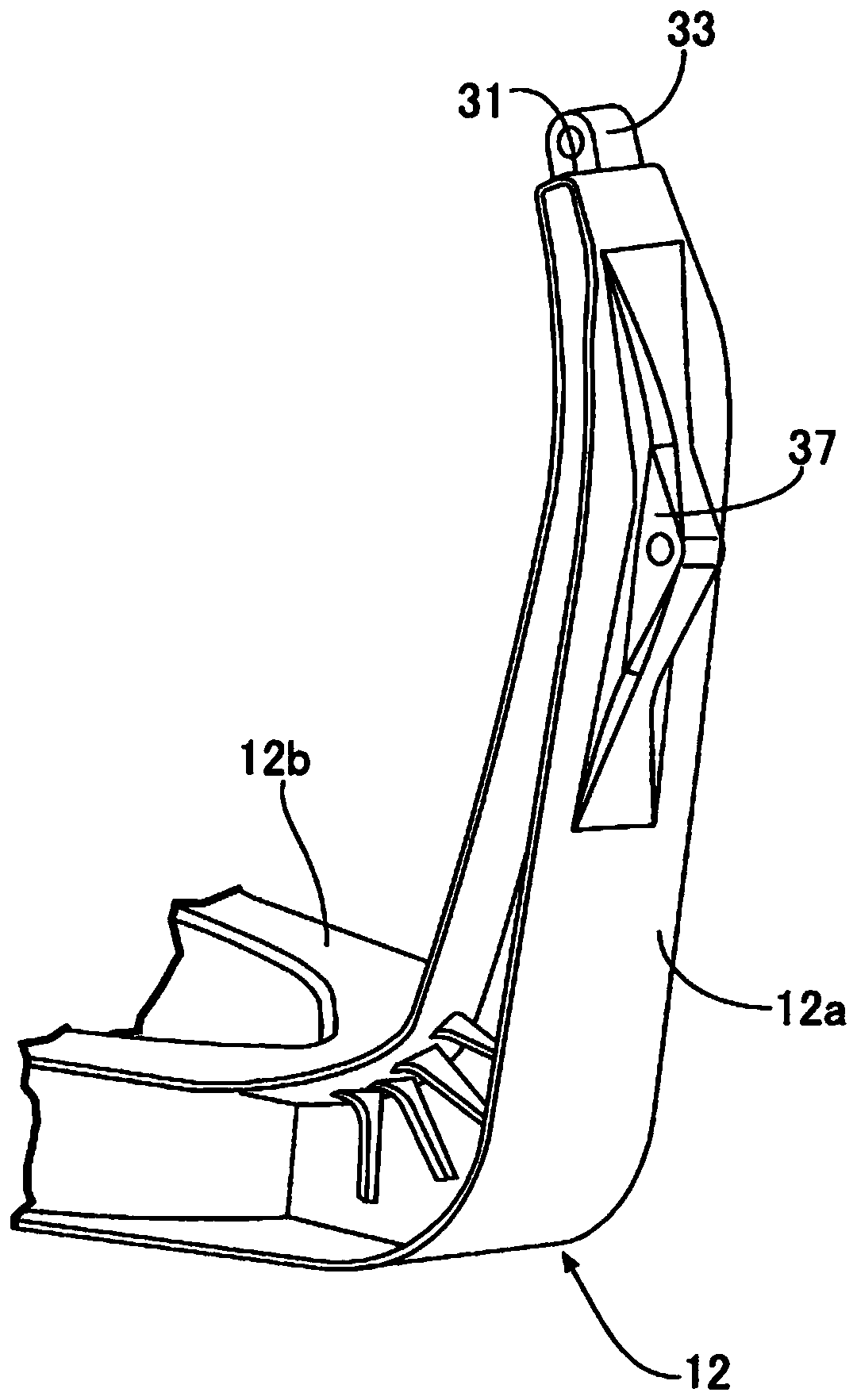

[0031] The main frame 12 is formed integrally with a lower frame portion 12a inclined rearward and downward from the head pipe 11, and a bottom frame extending rearward substantially horizontally from the rear end of the lower frame portion 12a. 12b, and a rear frame portion 12c extending rearward and upward from the rear portion of the bottom frame portion 12b.

[0032] exist figure 2 Among them, a unit swing type power unit P is swingably connected to the rear end portion of the bottom frame portion 12b of the main frame 12 via a link 15, and the rear wheel WR is pivotally supported on the power unit P. rear. In addition, a rear buffer unit 16 is provided between the rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com