Electronic component and method for manufacturing electronic component

A technology of electronic parts and manufacturing methods, which is applied in the direction of resistor manufacturing, capacitor manufacturing, and electrical component assembly of printed circuits, etc., can solve the problems of complicated positioning operations, difficult positioning, time-consuming, etc., and achieve simplified bonding operations, improved forming speed, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

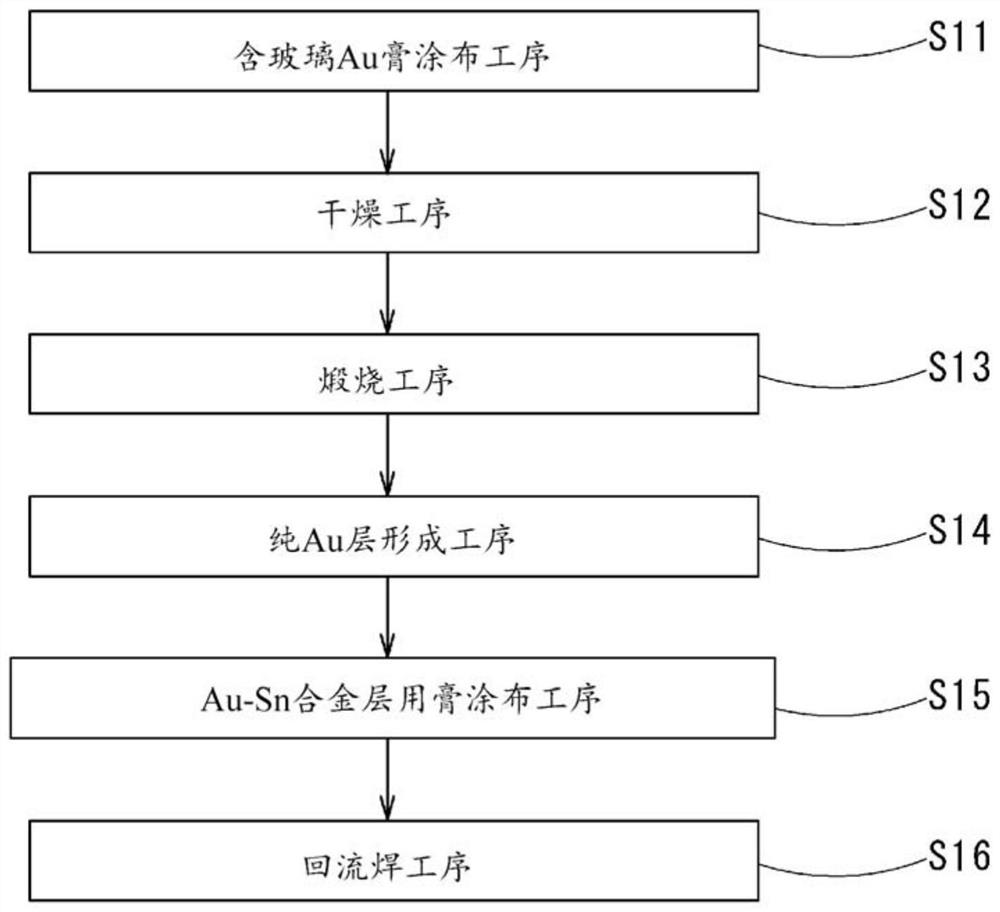

[0041] Hereinafter, the electronic component and the manufacturing method of the electronic component which concern on this invention are demonstrated using drawing.

[0042] [Schematic structure of electronic parts]

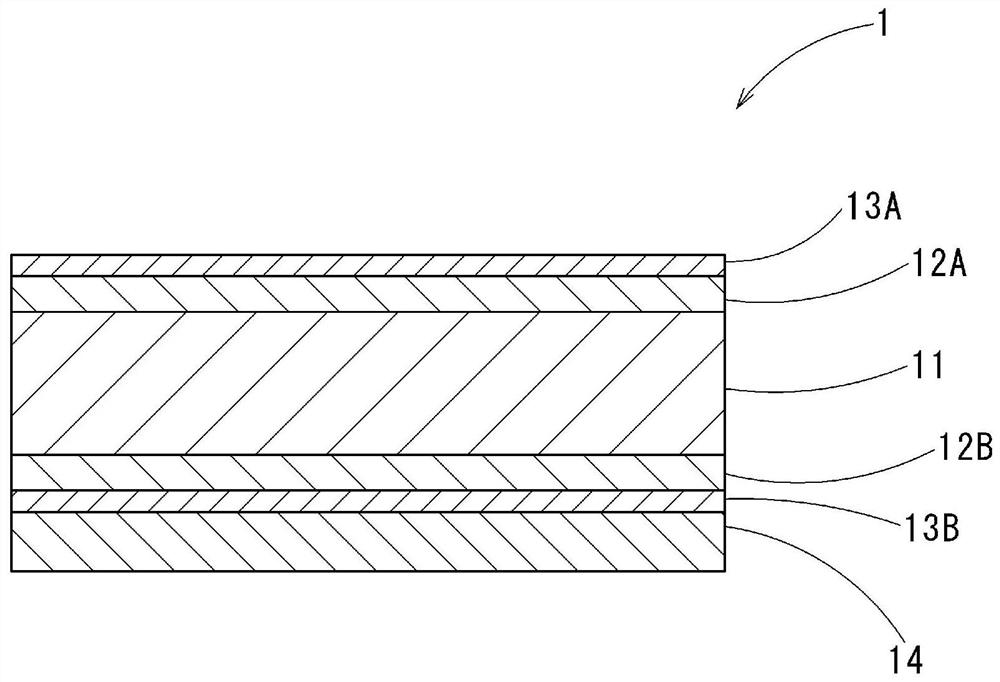

[0043] figure 1 It is a sectional view showing the electronic component 1 of this embodiment.

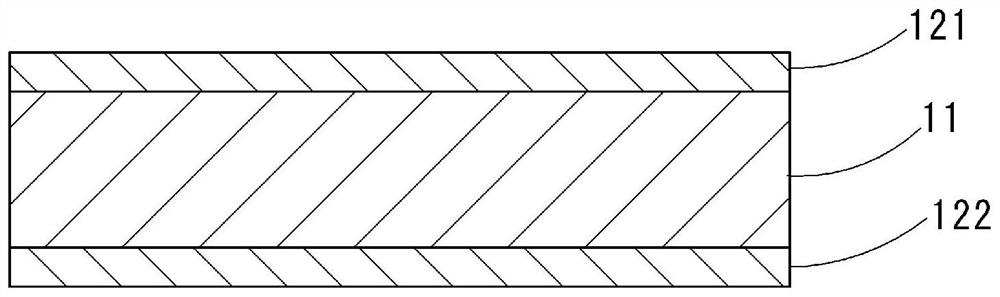

[0044] Such as figure 1 As shown, an electronic component 1 used as a thermistor or capacitor includes: a ceramic element 11; glass-containing Au layers 12A, 12B formed on both sides of the ceramic element 11; pure Au layers 13A, 13B formed on glass-containing Au layers 12A, 12B; and Au—Sn alloy layer 14, formed on pure Au layer 13B.

[0045] The electronic component 1 is fixed to a bonding object such as a substrate (not shown). Specifically, the electronic component 1 is bonded by disposing the Au—Sn alloy layer 14 of the electronic component 1 on the bonding surface of the bonding object, heating it, and cooling the molten Au—Sn alloy layer 14 to solidify it. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com