Structure for side section of vehicle body

A body and structure technology, applied in the field of body side structure, to achieve the effect of simple rigidity and improved rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

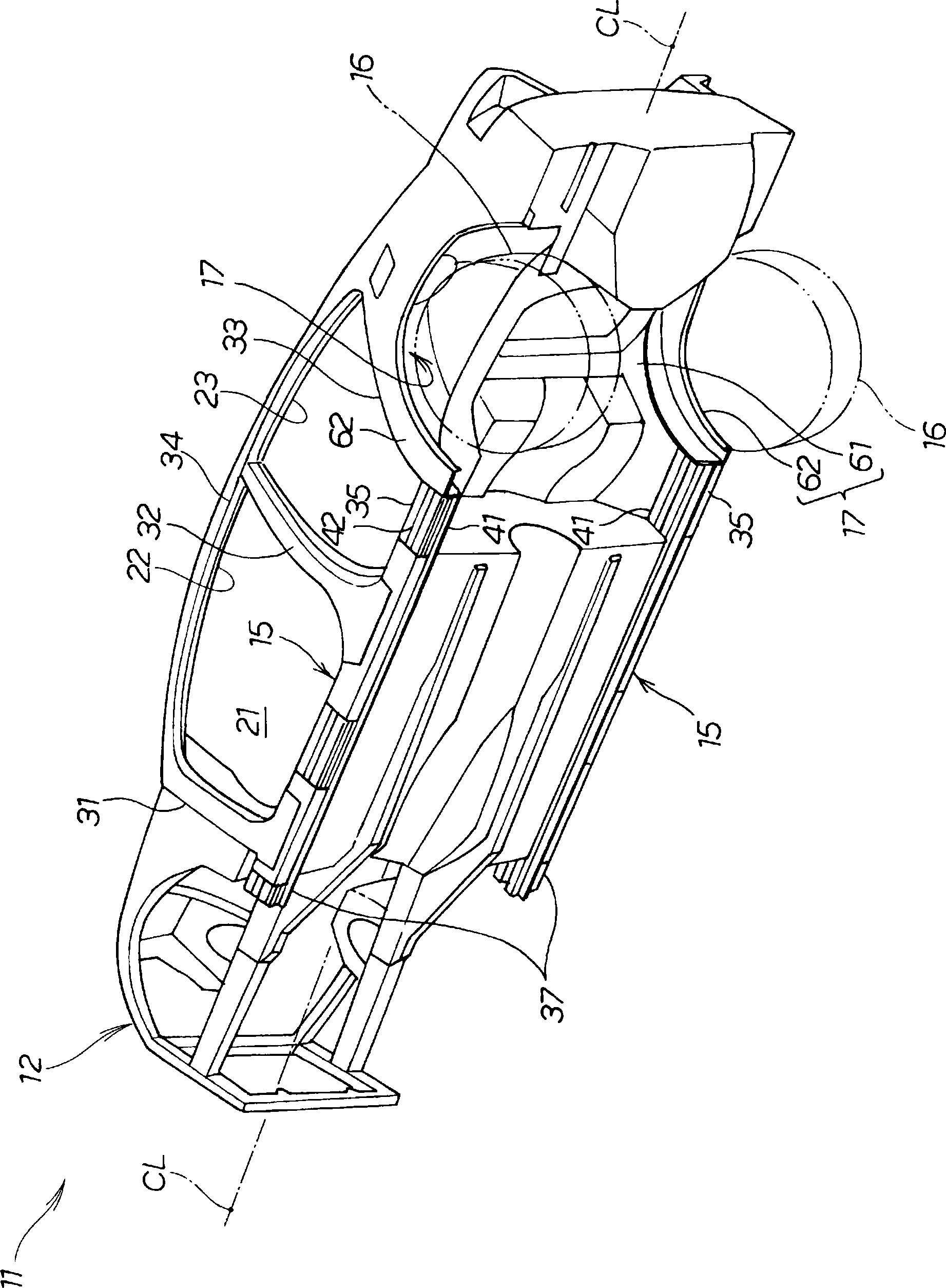

[0043] based on Figure 1 to Figure 8 The vehicle body of Example 1 will be described. Such as figure 1 As shown, the vehicle 11 is a four-door passenger car, and a vehicle cabin 21 is formed inside the central portion of the vehicle body 12 . The vehicle body 12 is constituted by a monocoque body, and is symmetrically formed with respect to a vehicle width centerline CL passing through the center of the vehicle 11 in the vehicle width direction and extending in the vehicle front-rear direction. The vehicle body 12 has a front door opening 22 and a rear door opening 23 on left and right side surfaces, respectively. The front and rear door openings 22 and 23 are opened and closed by unillustrated doors. Further, the vehicle body 12 includes left and right side sills 15 , left and right front pillars 31 , left and right center pillars 32 , left and right rear pillars 33 , left and right roof side rails 34 , and left and right rear wheel arches 17 .

[0044] The left and righ...

Embodiment 2

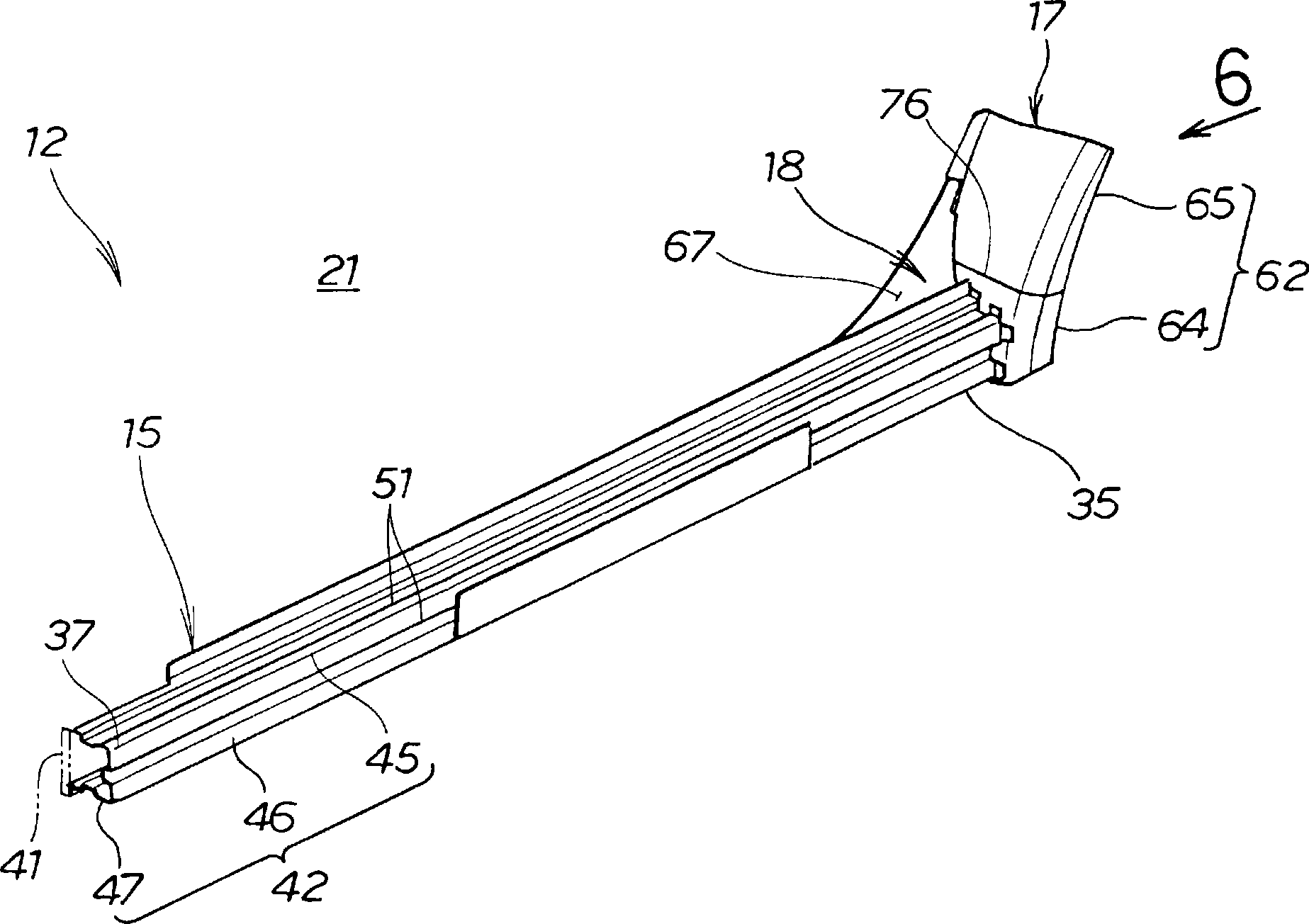

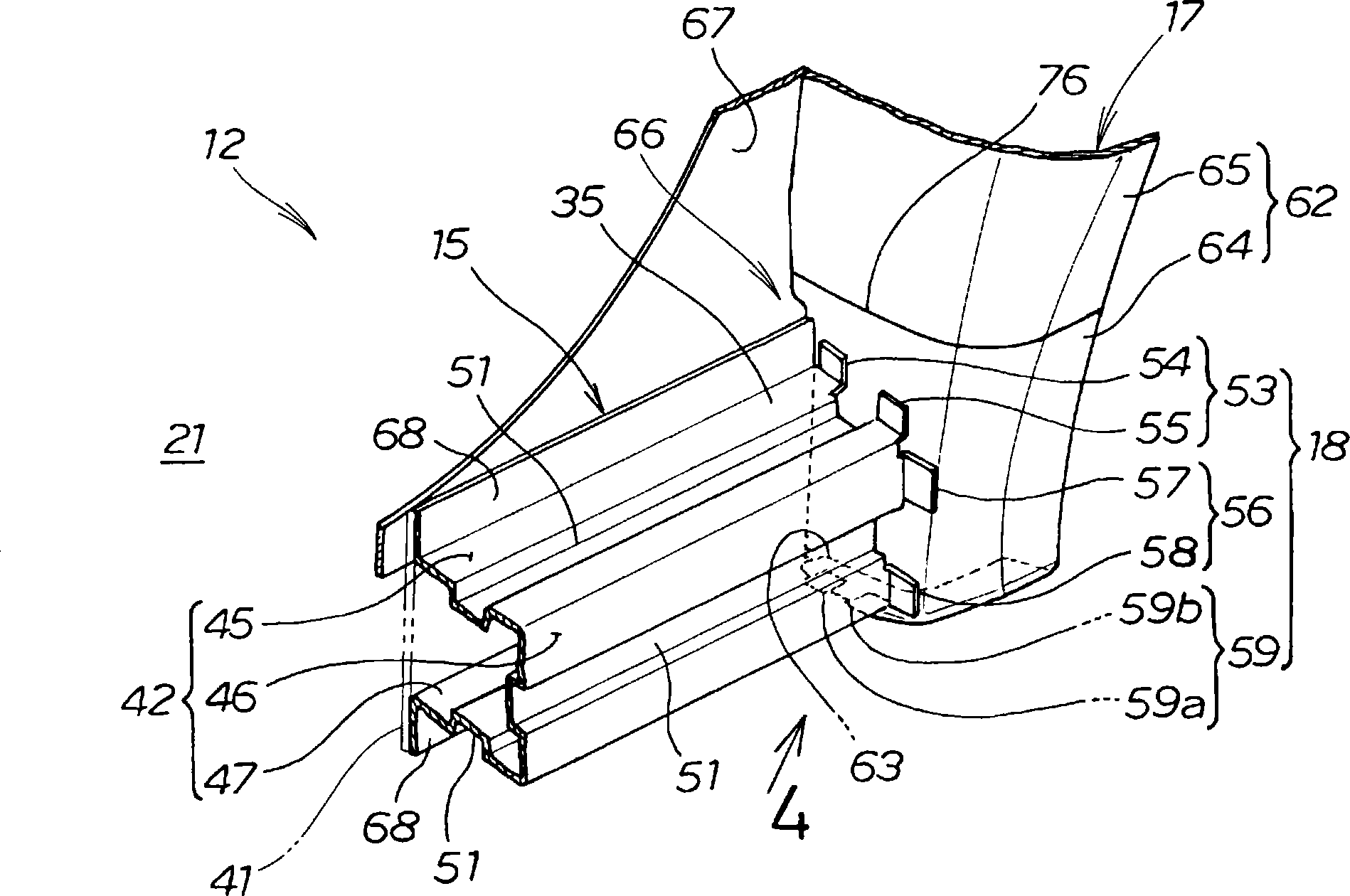

[0064] based on Figure 9 ~ Figure 13 The vehicle body of Example 2 will be described. The vehicle body 12A of Embodiment 2, except that Figure 1 to Figure 8 The joint member 18 on the left side of the illustrated embodiment 1 is changed to Figure 9 ~ Figure 13 Except for the joint member 18A shown on the left side, it has substantially the same structure as that of the vehicle body 12 of the first embodiment, and description thereof will be omitted. In addition, since the right joining member (not shown) has the same structure as 18 A of left joining members, description is abbreviate|omitted.

[0065] Such as Figure 9 ~ Figure 12 As shown, the left joining member 18A of the second embodiment is constituted by a separate member from the left side sill 15 . The left joining member 18A is overlapped and joined to the rear end portion 35 of the left side sill outer member 42 , that is, the outer peripheral surface of the rear end portion of the left side sill outer member...

Embodiment 3

[0076] based on Figure 14 as well as Figure 15 The vehicle body of Example 3 will be described. The vehicle body 12B of embodiment 3, except will Figure 9 ~ Figure 13 The joint member 18A on the left side of the illustrated embodiment 2 is changed to Figure 14 as well as Figure 15 Except for the joint member 18B on the left side shown, it has substantially the same structure as the vehicle body 12A of the second embodiment, and description thereof will be omitted. In addition, since the right joining member (not shown) has the same structure as the left joining member 18B, description is abbreviate|omitted.

[0077] Such as Figure 14 as well as Figure 15 As shown, the left joining member 18B of the third embodiment is constituted by a separate member from the left side sill 15 . The left joining member 18B is overlapped and joined to the rear end portion 35 of the left side sill outer member 42 , that is, on the inner surface of the rear end portion of the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com