Anti-mildew liquid spraying apparatus of vehicle float glass production line, and method thereof

A float glass and spraying device technology, applied in the field of float glass, can solve the problems of affecting glass quality, non-military coverage of anti-mildew liquid, uneven coverage of anti-mildew liquid, etc., and achieve the effect of improving product quality and reasonable coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

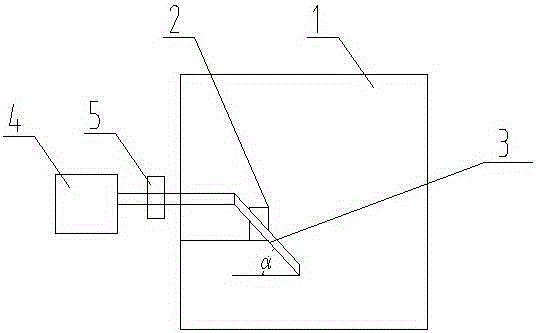

[0015] The set of high-pressure shower heads 3 is composed of four or more high-pressure shower heads.

[0016] A. When the glass thickness is 1.6mm and the glass transport speed is ≥10m / min, the angle between the spray line and the horizontal plane of a group of high-pressure nozzles 3 is α, α is 85-90°, and the spray speed is 9-10L / h;

[0017] B. When the glass thickness is 1.8mm and the glass transport speed is ≥10m / min, the angle between the spray line and the horizontal plane of a group of high-pressure nozzles 3 is α, α is 65-80°, and the spray speed is 9-10L / h;

[0018] C. When the glass thickness is 2.1mm and the glass transport speed is ≥10m / min, the angle between the spray line and the horizontal plane of a group of high-pressure nozzles 3 is α, α is 55-70°, and the spray speed is 9-10L / h;

[0019] D. When the thickness of the glass is 2.3mm and the glass transportation speed is ≤10m / min, the angle between the spray line and the horizontal plane of a group of high-pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com