A method for extracting alliin by reverse micellar system

A technology of reverse micelle and alliin, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., to achieve the effects of convenient operation, high recovery rate and short extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

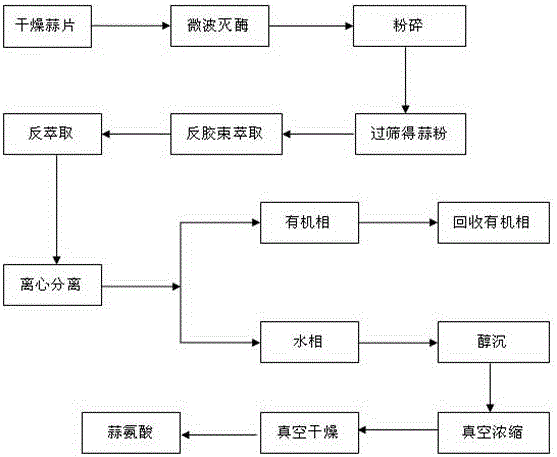

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of garlic powder

[0026] Take the dried garlic slices, microwave them to inactivate enzymes, and pulverize them on a high-speed pulverizer, and pass through an 80-mesh sieve after pulverization;

[0027] (2) Preparation of reverse micellar solution

[0028] Weigh 1.09g of cetyltrimethylammonium bromide (CTAB), put it in a 100mL Erlenmeyer flask, add 54mL of n-heptane and 6mL of n-octanol at the same time, ultrasonically shake to dissolve it, and then add an appropriate amount of 0.5mol The phosphate buffer solution of KCl in / L, adjust the buffer solution so that its pH is 7.0, continue ultrasonic oscillation until CTAB is completely dissolved, the solution is transparent, and a reverse micellar solution is obtained;

[0029] (3) Pre-extraction of alliin in reverse micellar solution

[0030] Take 60mL of reverse micellar solution in a Erlenmeyer flask, add 0.4g of garlic powder, ultrasonically extract at 40°C for 30min, then centrifuge at 3000r / min fo...

Embodiment 2

[0035] (1) Preparation of garlic powder

[0036] Take dried garlic slices, microwave them to inactivate enzymes, and then pulverize them on a high-speed pulverizer. After pulverization, pass through an 80-mesh sieve, and the obtained garlic powder is the garlic powder required for the test;

[0037] (2) Preparation of reverse micellar solution

[0038] Weigh 1.09g of cetyltrimethylammonium bromide (CTAB), put it in a 100mL Erlenmeyer flask, add 54mL of n-heptane and 6mL of n-octanol at the same time, ultrasonically shake to dissolve it, and then add an appropriate amount of 0.3mol / L of KCl phosphate buffer solution, adjust the buffer solution so that its pH is 6.0, continue ultrasonic oscillation until CTAB is completely dissolved and the solution is transparent;

[0039] (3) Pre-extraction of alliin in reverse micellar solution

[0040] Take 60mL of the above reverse micellar solution in a conical flask, add 1.0g of garlic powder, ultrasonically extract at 25°C for 40min, ...

Embodiment 3

[0045] (1) Preparation of garlic powder

[0046] Take dried garlic slices, microwave them to inactivate enzymes, and then pulverize them on a high-speed pulverizer. After pulverization, pass through an 80-mesh sieve, and the obtained garlic powder is the garlic powder required for the test;

[0047] (2) Preparation of reverse micellar solution

[0048] Weigh 1.09g of cetyltrimethylammonium bromide (CTAB), put it in a 100mL Erlenmeyer flask, add 54mL of n-heptane and 6mL of n-octanol at the same time, ultrasonically shake to dissolve it, and then add an appropriate amount of 0.5mol / L of KCl phosphate buffer solution, adjust the buffer solution so that its pH is 6.0, continue ultrasonic oscillation until CTAB is completely dissolved and the solution is transparent;

[0049] (3) Pre-extraction of alliin in reverse micellar solution

[0050] Take 60mL of the above reverse micellar solution in a Erlenmeyer flask, add 1.0g of garlic powder, ultrasonically extract at 50°C for 5min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com