Method for extracting and purifying lignin peroxidase by using reverse micelles

A peroxidase and reverse micelle technology, which is applied in the field of extraction and purification of enzymes, can solve the problems of reducing the effectiveness of enzyme catalysis, hindering the progress of reverse micelle extraction and purification enzymes, and volatile inactivation of enzyme proteins, and achieves convenient operation. , The effect of short extraction time and high degree of purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

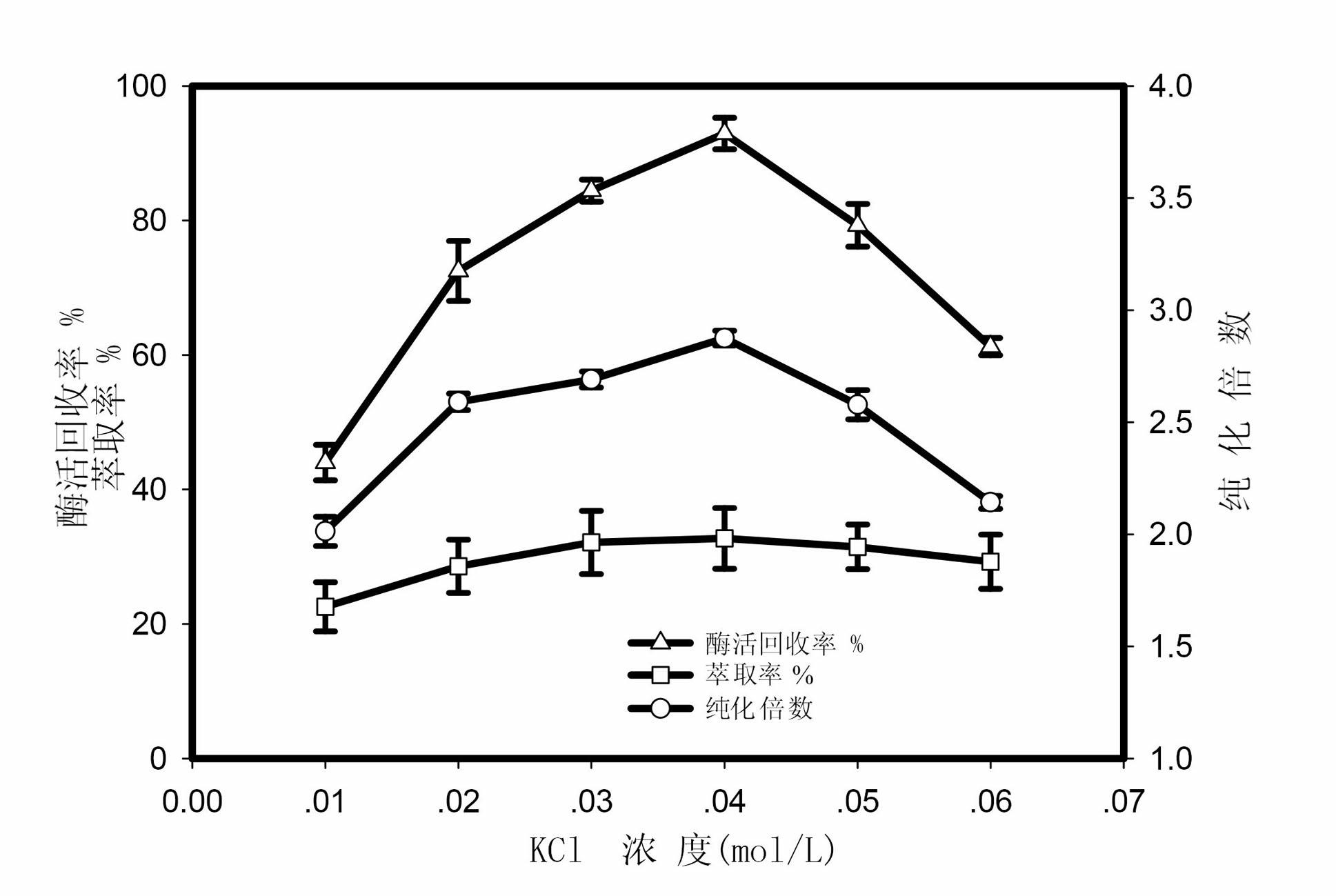

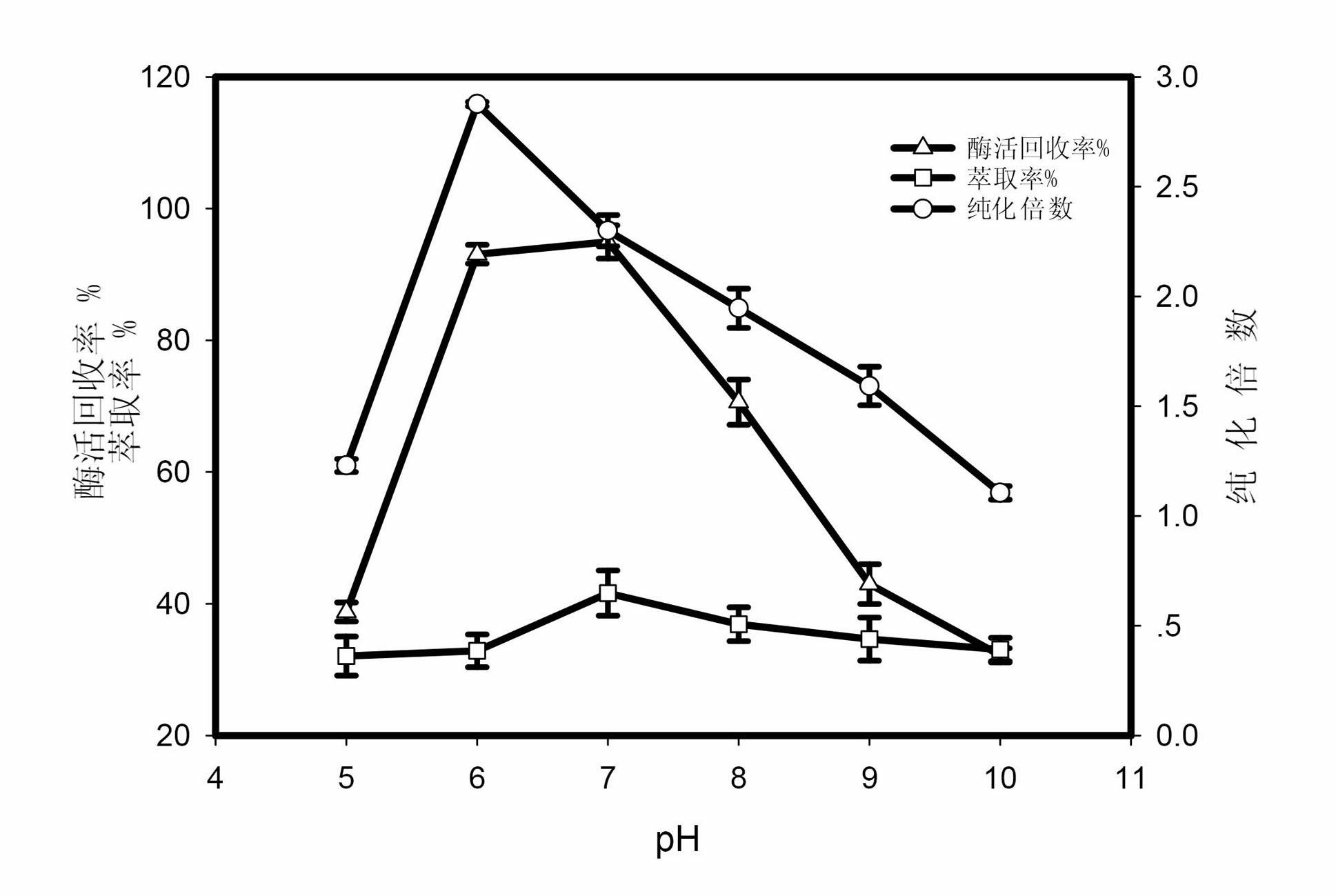

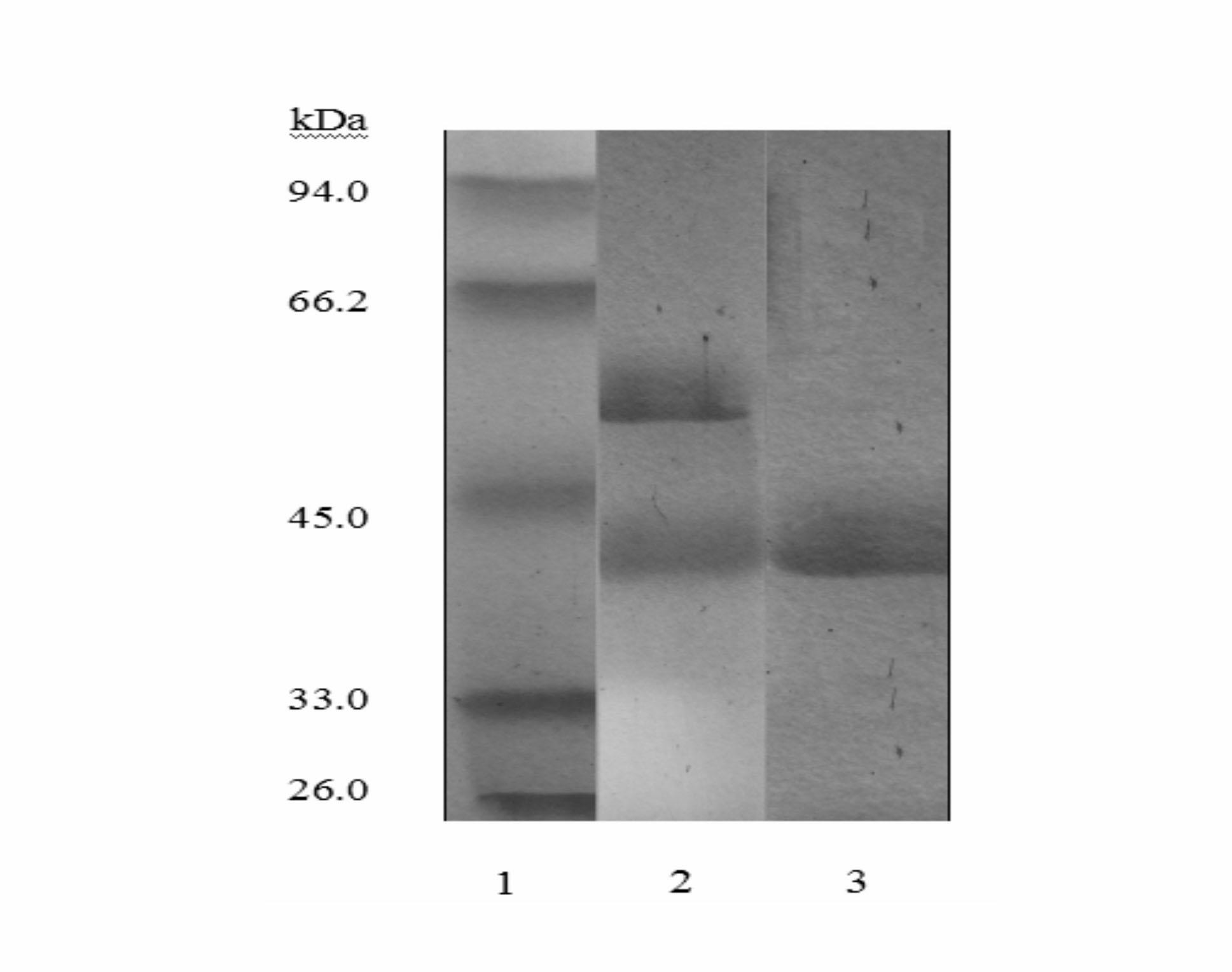

[0026] A method for reverse micellar extraction and purification of lignin peroxidase of the present invention, specifically comprising the following steps:

[0027] (1) Preparation of reverse micelle solution: the reverse micelle solution of this example includes biosurfactant, isooctane and n-hexanol, wherein the surfactant is rhamnolipid; After cultivation, it was dissolved in a mixture of isooctane and n-hexanol with a volume ratio of 1:1, and prepared into a 40mL reverse micellar solution with a concentration of 2.75mmol / L (rhamnolipid-n-hexanol-isooctane solution ).

[0028] (2) Pre-extraction process: put 100mL of conventional liquid fermentation medium after autoclaving in a 500mL Erlenmeyer flask, and inoculate 4×10 8 Put the spores of Phanerochaete chrysosporium BKM-F-1767 (not limited to this strain, other Phanerochaete chrysosporium strains are acceptable) into the liquid fermentation medium, and place on a shaking table at a temperature of 37°C and a speed of 150...

Embodiment 2

[0035] A method for reverse micellar extraction and purification of lignin peroxidase of the present invention, specifically comprising the following steps:

[0036] (1) Preparation of reverse micelle solution: the reverse micelle solution of this example includes biosurfactant, isooctane and n-hexanol, wherein the surfactant is rhamnolipid; After cultivation, it was dissolved in a mixture of isooctane and n-hexanol with a volume ratio of 1:1.2, and prepared into a 40mL reverse micellar solution with a concentration of 3.0mmol / L (rhamnolipid-n-hexanol-isooctane solution ).

[0037] (2) Pre-extraction process: put 100mL of conventional liquid fermentation medium after autoclaving in a 500mL Erlenmeyer flask, and inoculate 5×10 8 Put the spores of Phanerochaete chrysosporium BKM-F-1767 (not limited to this strain, other Phanerochaete chrysosporium strains are acceptable) into the liquid fermentation medium, and place on a shaker at 38°C and 180r / min. Cultivate for 8 days, use ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com