Overturn-preventing falling-preventing attached lifting scaffold

A lifting scaffolding and attachment technology, applied in the field of scaffolding, can solve problems such as failure of anti-falling devices, increased manufacturing cost of anti-falling components in structure, unfavorable promotion and use, etc., and achieve the effect of simplifying structure and operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

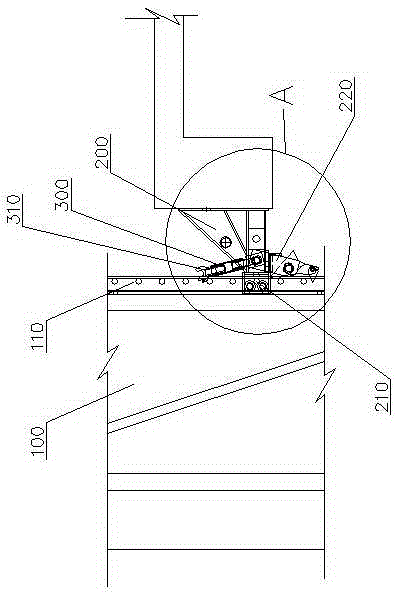

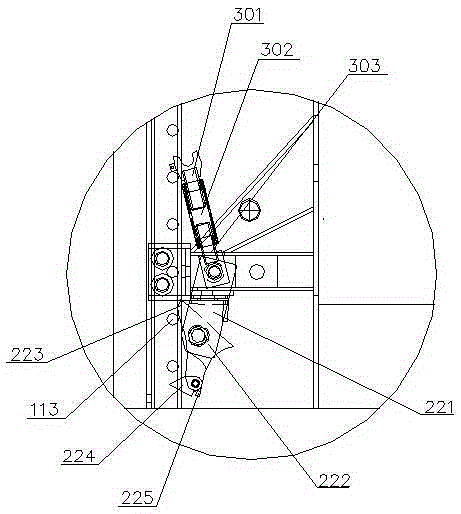

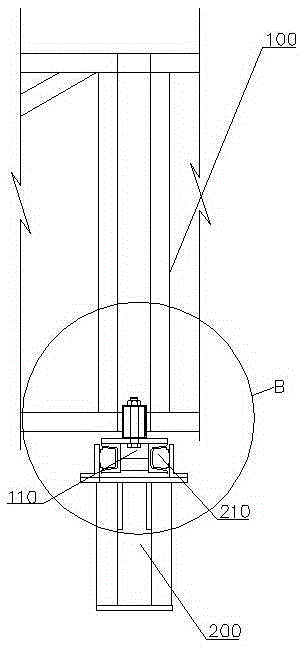

[0023] See Figure 1 to Figure 4 , As shown in the illustration, an attached lifting scaffold for overturning and falling prevention. The attached lifting scaffold includes a frame body 100 and a guide seat 200. The frame body 100 is arranged in front of the building wall and the guide seat 200 The rear side is relatively fixed to the building wall, the rear side of the frame body 100 is provided with at least two anti-overturning lifting rails arranged at a distance in the left and right direction, and the front side of the guide seat 200 is provided with an anti-overturning rail that cooperates with the anti-overturning lifting rail. The guide wheel assembly, the above-mentioned anti-overturning lifting rail includes a left rail component 111 extending in the up-down direction, a right rail component 112 extending in the up-down direction, and a number of support columns 113 arranged at intervals along the up-down direction. It extends in the left-right direction and is suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com