Glass fiber reinforced plastic chimney butt seam assembling and winding apparatus

A fiberglass chimney and winding device technology, which is applied in the direction of building types, buildings, towers, etc., can solve the problems of difficulty in ensuring the quality of hand-pasted joints, low production efficiency, and high costs, so as to improve joint strength and increase production efficiency , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

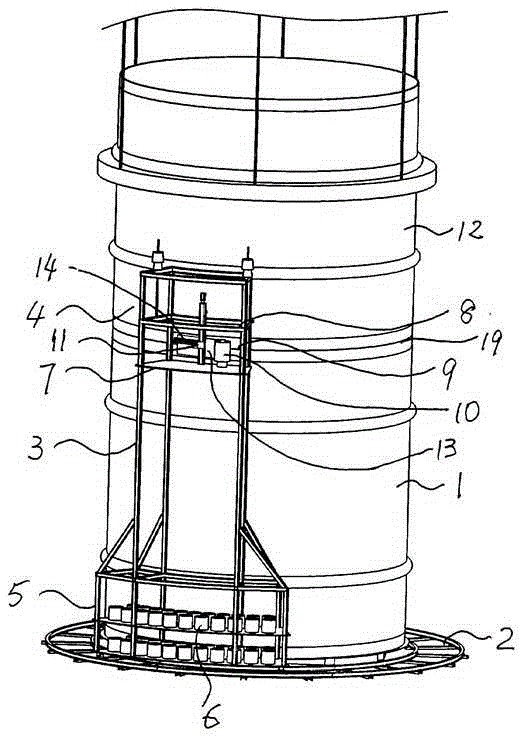

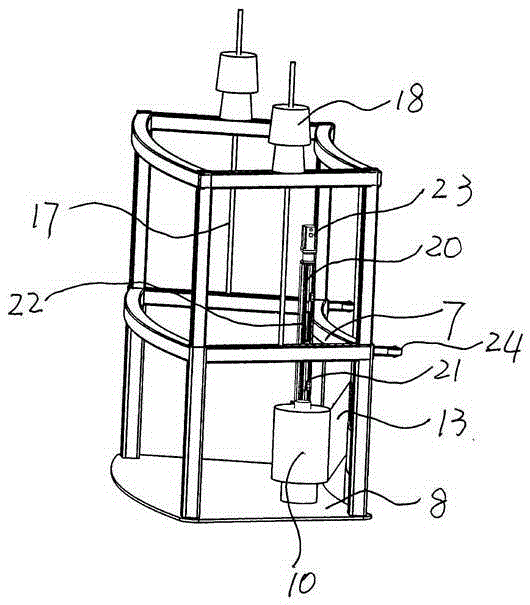

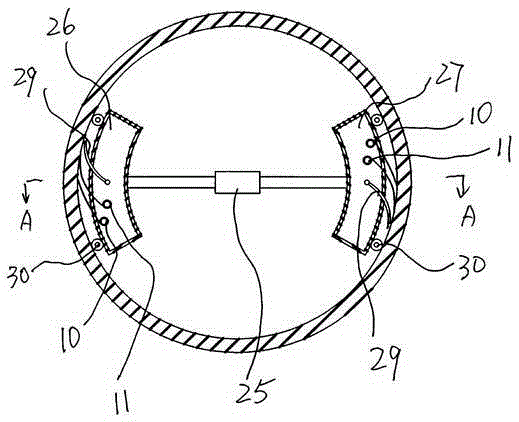

[0031] The structure and working principle of a fiberglass chimney assembly and seam winding device provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] Such as figure 1 , 2 As shown, it is a structural schematic diagram of a fiberglass chimney assembly butt joint outer wall winding device provided by the present invention. Its structure includes a surrounding track 2 arranged on the outside of the lower section of the glass fiber reinforced plastic cylinder 1, and a trolley composed of upper and lower frames 4 and 5 connected by connecting rods 3 on the track; on the above-mentioned trolley (preferably The lower frame body 5 that constitutes the trolley is provided with a resin fiber yarn mechanism 6, and the upper frame body 4 is composed of a fan-shaped frame 9 composed of upper and lower fan-shaped plates 7, 8 corresponding to the arc shape of the outer surface of the glass fiber reinforced pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com