Heat-insulation type aluminum alloy door window

A technology of aluminum alloy doors and windows and engaging parts, which is applied in the installation of windows/doors, window/door frames, and window glass, etc., can solve the problems of loose aluminum alloy doors and windows, complicated installation, and difficulty in achieving tight fit of parts. Achieve the effect of avoiding the difficulty of fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

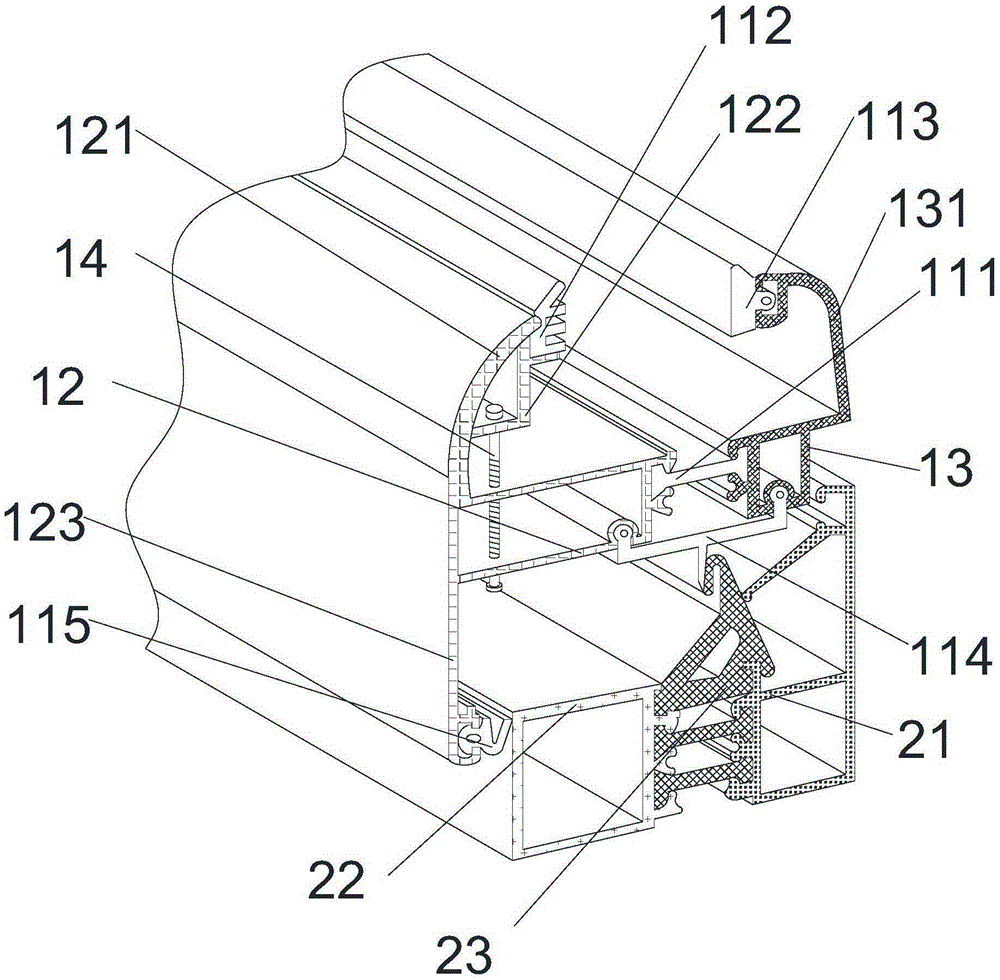

[0022] refer to figure 1 As shown, a heat-insulating aluminum alloy door and window proposed by the present invention includes an opening fan and a frame body, and the opening fan is rotatably mounted on the frame body.

[0023] The opening fan is composed of the first rubber strip group, the inner fan 12 of the opening fan, the outer fan 13 of the opening fan and the pull rod 14;

[0024] The first rubber strip group includes a connecting strip 111, a first compression strip 112, a second compression strip 113, a first sealing strip 114 and a second sealing strip 115; From the beginning, the inner leaf 12 of the opening fan and the outer leaf 13 of the opening fan are both provided with a first card slot adapted to the first protrusion, and are installed on opposite sides of the connecting bar 111 through the first protrusion.

[0025] The inner fan 12 of the opening fan is equipped with a first arc-shaped plate 121 on one side away from the frame body, and the first arc-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com