Metal material monoaxial performance test clamp

A technology for testing fixtures and metal materials, which is applied in the field of uniaxial performance test fixtures for metal materials, can solve the problems of not being able to increase the loading rate range, reduce the transmission stiffness of the whole machine, etc., and achieve the benefits of system control and measurement of geometric quantities, The mechanical transmission is stable and reliable, and the effect of increasing the load loading rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

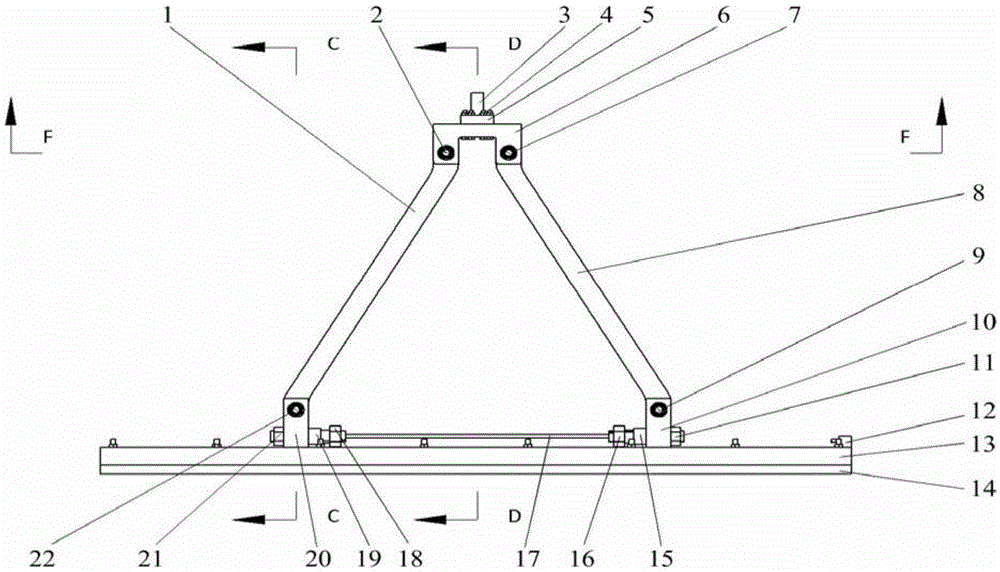

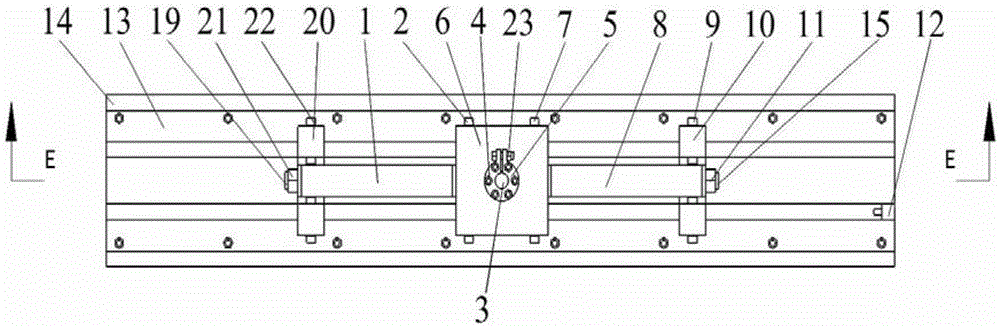

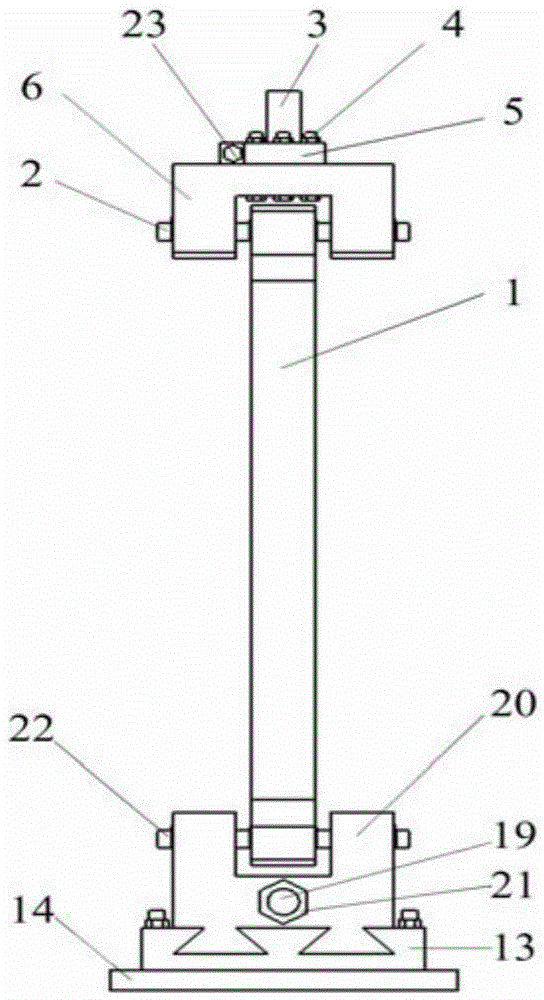

[0029] A specific embodiment of the present invention is structured as Figure 1 to Figure 8 As shown, the metal material uniaxial performance test fixture mainly includes three parts: a loading device, a transfer device and a clamping device.

[0030] The loading device is composed of a loading shaft 3 , a connecting plate 5 and a connecting bracket 6 arranged sequentially from top to bottom. One end of the loading shaft 3 is fixed on the connecting plate 5 through a locking bolt and nut combination 23, and the other end is connected with the external load, and the load or displacement applied by the external load is transmitted to the entire performance test fixture. The connecting plate 5 utilizes six sets of The fixed bolt and nut combinati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com