Tension tester

A tester and tension technology, applied to instruments, using stable tension/pressure to test the strength of materials, measuring devices, etc., can solve the problems of inapplicable results, convenience needs to be further improved, etc., to achieve short measurement preparation time and improve safety Good reliability and visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

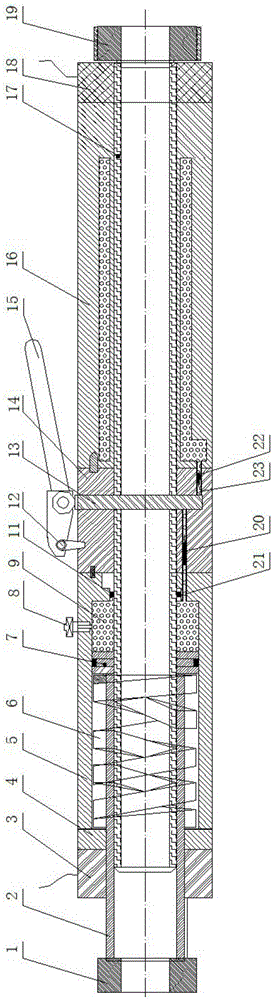

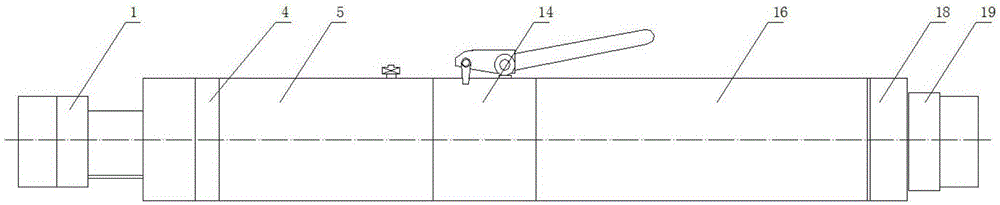

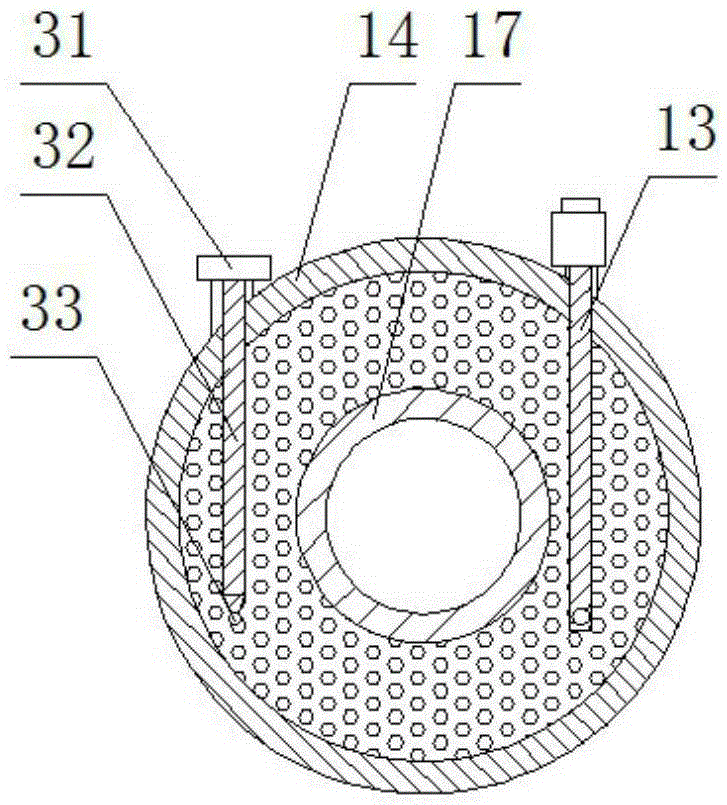

[0040] A tensile tester, comprising an annular inner casing 17, a pressurized hydraulic cylinder 14, an oil cylinder chamber 5, an oil storage chamber 16, a pressure detector 18, a displacement detector 3, and two cable end safety lock caps 1, 19. The middle part of the inner casing is hollow, which is used to wear the cable to be tested, and seal the cable inside the casing to ensure safety. The pressurized hydraulic cylinder is installed in the middle of the outer edge of the shell, and the oil storage chamber and the oil cylinder chamber are coaxially installed on both sides of the pressurized hydraulic cylinder, and the adjacent cavities are sealed as required. 1. The pressure oil between the cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com