Method for measuring the thickness of boiler water pipes

A measurement method and boiler technology, applied in boiler water pipes, components of steam boilers, steam boilers, etc., can solve the problems of reduced boiler operation efficiency and long construction period of boiler water pipes, and achieve the effect of shortening construction period and stable operation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Next, with reference to the accompanying drawings, specific embodiments of the present invention will be described for understanding of the present invention.

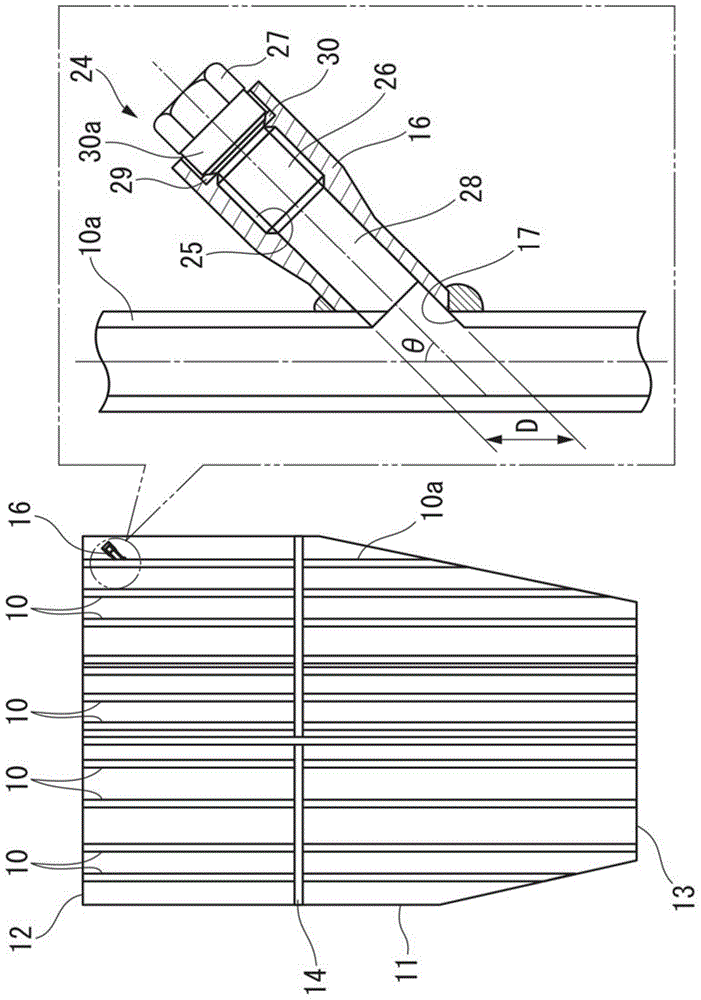

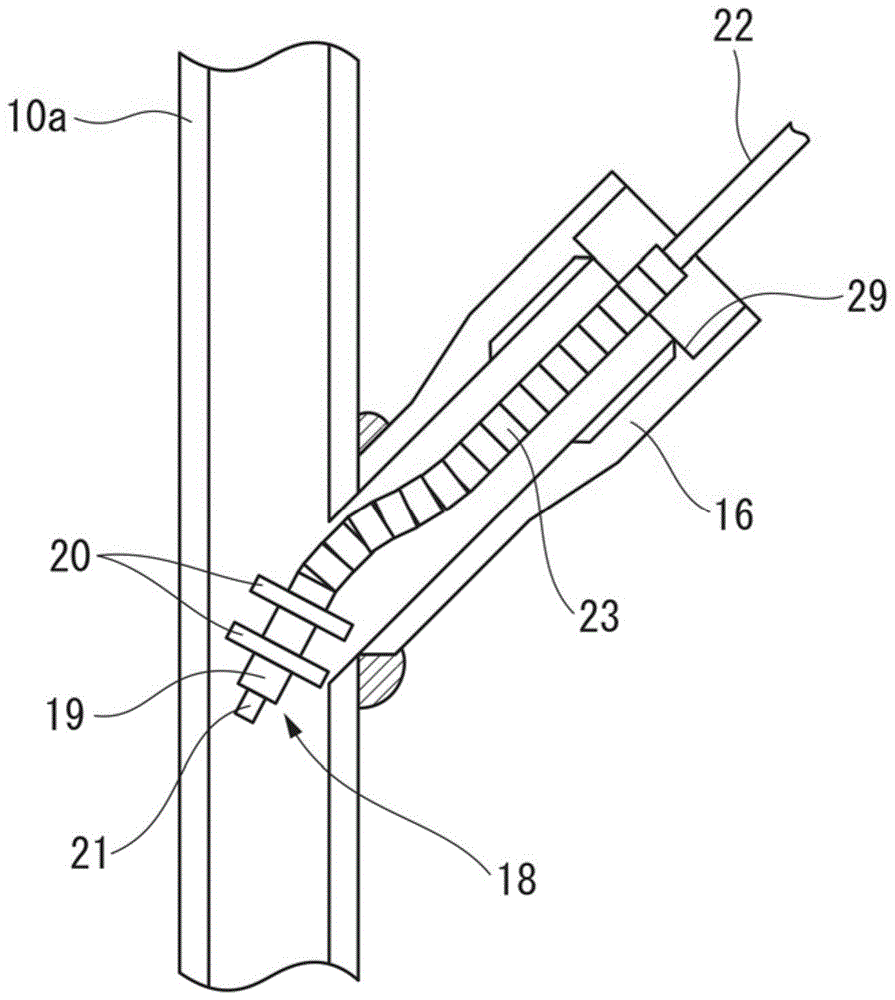

[0026] First, the boiler water pipe 10a in an upright state and other boiler water pipes 10 in an upright state to which the method for measuring the thickness of a boiler water pipe according to an embodiment of the present invention is applied (refer to figure 1 )Be explained.

[0027] A plurality of boiler water tubes 10, 10a are vertically arranged at predetermined intervals in the boiler water tube panel 11, and water passes through the inside thereof. The upper ends of the respective boiler water pipes 10, 10a are suspended from beams of the building, whereby the arrangement of the respective boiler water pipes 10, 10a in the boiler water pipe panel 11 is fixed.

[0028] Moreover, the intermediate part in the longitudinal direction of each boiler water tube 10,10a communicates with the header 14. As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com