A thread processing method with large modulus and large lead

A technology of thread processing and large lead, applied in the field of thread processing, can solve the problems of difficult thread processing, long working length, long processing cycle, etc., and achieve the effect of improving processing efficiency, reducing vibration and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

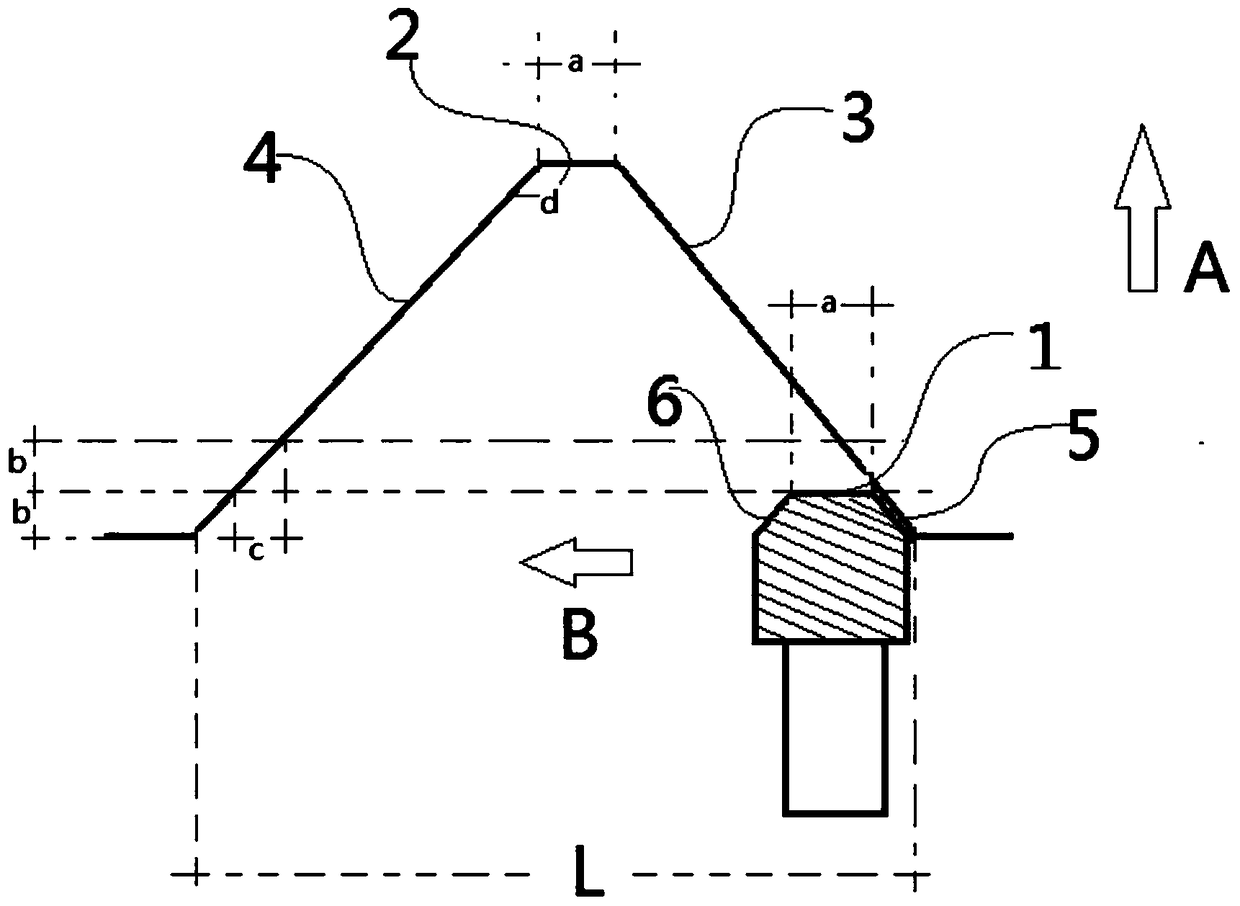

[0030] A thread processing method with large modulus and large lead, cutting the threading tool radially toward the workpiece to form an initial thread groove with a depth b; after the threading tool exits, the initial thread groove with a depth b Move the threading tool in the B direction until the thread opening distance reaches L, and complete the first layer of processing; then move the threading tool in the A direction to the second layer of thread grooves with a cutting depth of b, and move the threading in the A direction Before the knife starts cutting the second layer, move the top of the threading tool to the right side wall of the thread for a horizontal distance c, and then cut. After the threading tool exits, move the threading tool in the direction of B until the distance reaches Complete the processing of the second layer; according to the above method in turn, move the threading tool in the B direction until the distance reaches a, and during the processing of ...

Embodiment 2

[0035]On the basis of Embodiment 1, the others are the same as in Embodiment 1, the threading cutter is moved in the B direction, and the contact point of the threading cutter is softened before moving. The softening treatment is to use neutral oxygen-pyridine to heat to 700-800° C., and rapidly cool to room temperature with water.

Embodiment 3

[0037] On the basis of Embodiment 1, the others are the same as in Embodiment 1. The threading cutter is moved in the direction A, and the contact point 1 of the threading cutter is softened to a depth of 0.1-0.5 before moving. mm. The softening treatment is carried out by heating to 700-800°C with neutral oxygen-flame acetylene, and rapidly cooling to room temperature with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com