An auxiliary equipment for overhead pipeline welding

A technology for overhead pipelines and auxiliary equipment, applied in welding/cutting auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of unusable machinery, large labor consumption, large risk factor, etc., and achieve high positioning and centering accuracy , High safety, precise welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

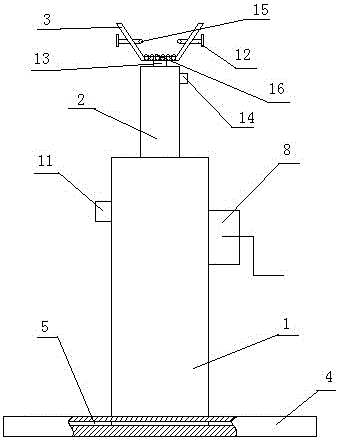

[0012] Below in conjunction with accompanying drawing, the present invention is further described:

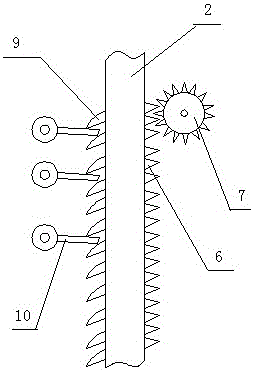

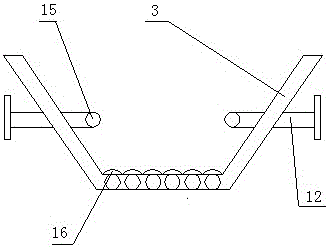

[0013] As shown in the drawings, an auxiliary equipment for overhead pipeline welding is characterized in that the equipment is composed of a rough positioning mechanism, a safety mechanism, a fine-tuning mechanism and a laser centering mechanism. The rough positioning mechanism is composed of a support rod 1, a lifting rod 2. The fixed claw 3 and the fixed base 4 are composed. The lower end of the support rod 1 is connected with the fixed base 4. The fixed base 4 is provided with a slideway 5. The lower end of the support rod 1 slides left and right in the slideway 5 to realize the left and right of the overhead pipeline. Coarse positioning, the inside of the support rod 1 is provided with an upper and lower sliding pipe with an open upper end, and the sliding pipe is provided with a lifting rod 2. One side of the lifting rod 2 located inside the sliding pipe is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com