A method of precisely controlling the color of bamboo

A bamboo material and color technology, applied in wood treatment, wood processing equipment, wood treatment details, etc., can solve the problems of difficult precise control of steam pressure, bamboo color difference, high cost, etc., to achieve easy product quality assurance, easy temperature control, and easy color difference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Establish a three-dimensional sample library for bamboo heat treatment

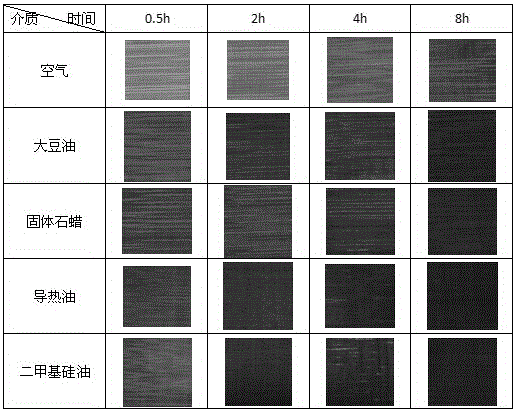

[0023] The colors of moso bamboo slices after being treated for 0.5, 2, 4, and 8 hours in 200°C air, soybean oil, solid paraffin, heat transfer oil, and simethicone oil are shown in figure 1 . This table can be regarded as one layer of the sample library, and then more layers are built under the same conditions as the table at other temperatures, finally forming a three-dimensional library.

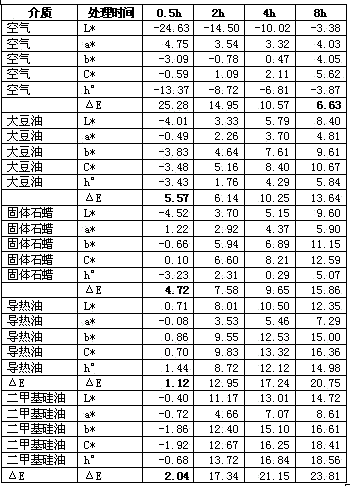

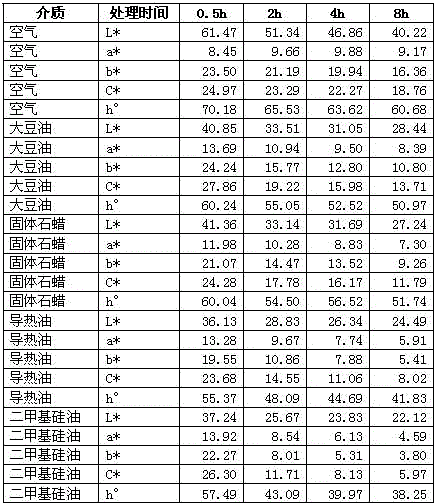

[0024] 2) Convert sample library to color library

[0025] Use a colorimeter to measure the CIEL*a*b* chromaticity of the sample, the test conditions are: D65 light source 10°observation angle, the test index is lightness index L*, red-green axis chromaticity index a*, yellow-blue axis chromaticity index b *, saturation C*, hue h°, transform the three-dimensional sample library obtained in step 1) into a color library.

[0026]

[0027] 3) Primary selection of heat treatment scheme

[0028] Take the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com