Shaft replacing device used for photovoltaic welding strip collecting machine and photovoltaic welding strip collecting machine

A photovoltaic welding ribbon and wire take-up machine technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems affecting production efficiency, machine shutdown, cumbersome operation, etc., to avoid position placement errors, The effect of avoiding machine downtime and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

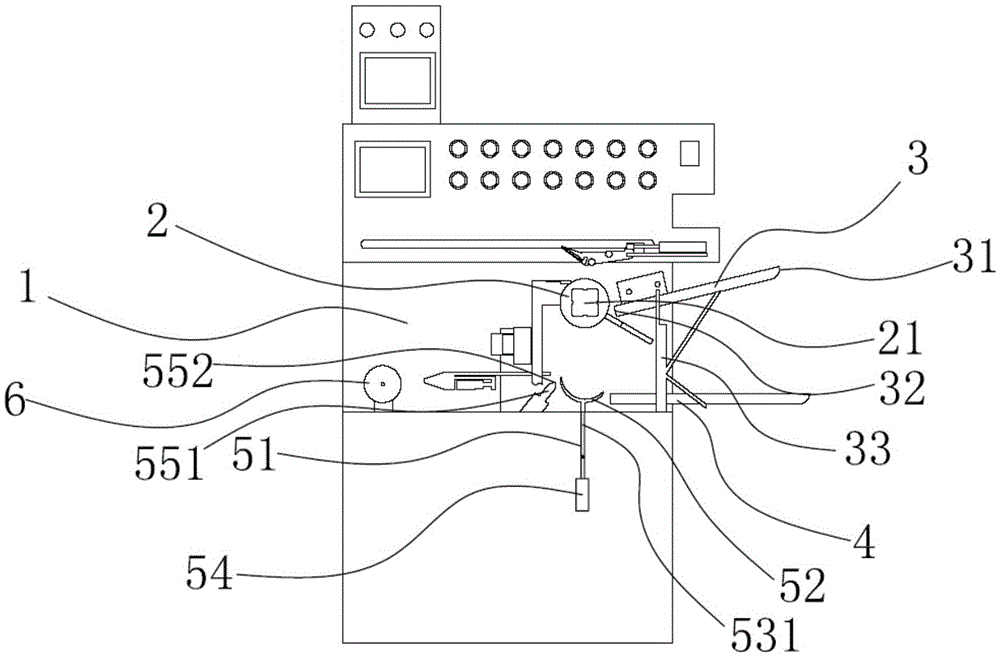

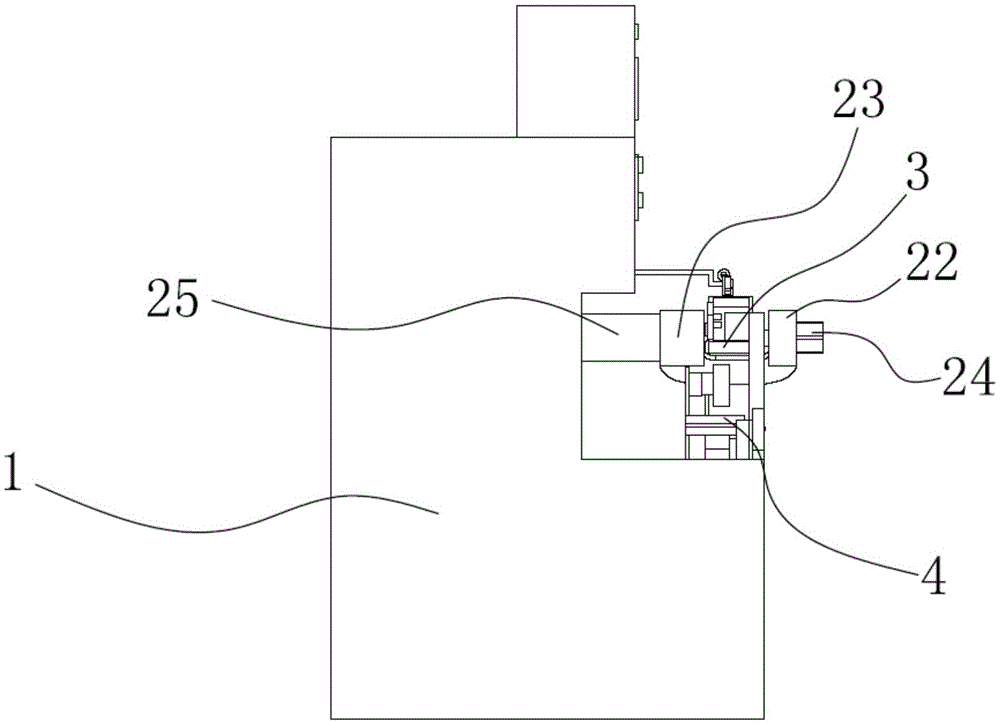

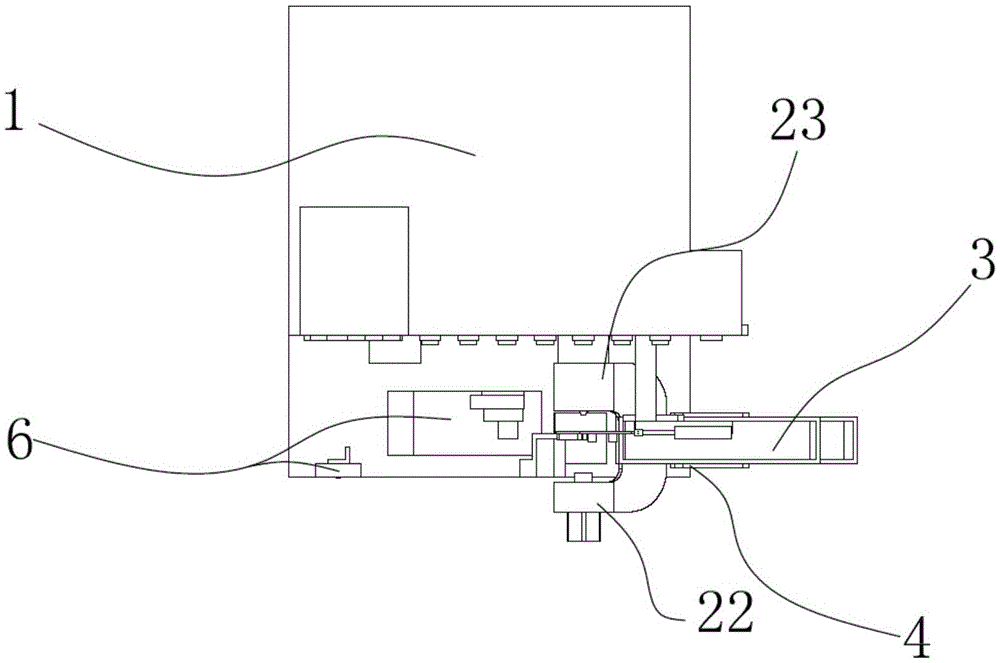

[0046] In order to achieve the purpose of the present invention, as Figure 1-4 As shown, in some embodiments of the shaft changing device applied to the photovoltaic ribbon take-up machine of the present invention, it includes: a clamping and rotating mechanism 2, which is installed on the photovoltaic ribbon take-up machine, and the clamping and rotating mechanism 2. Clamping and circumferential rotation are driven by the first drive unit 21. The clamp rotating mechanism 2 clamps the I-shaped shaft and drives the I-shaped shaft to rotate in the circumferential direction; Arranged obliquely from high to low, the discharge end 32 is connected to the fixture rotation mechanism 2; the discharge mechanism 4 is horizontally arranged and fixed below the feed mechanism 3; the lifting mechanism 5 is driven by the second drive unit 51 Drive to move ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap