Sewage treatment system with integral ceramic membrane filters

A sewage treatment system and ceramic membrane technology, which is applied in the field of sanitation special vehicles, can solve the problems of not being able to fully exert the maximum efficiency of the filter, low sewage treatment efficiency, and high maintenance costs, so as to reduce the time for adding water and discharging sewage in the return journey, and improve The effect of single cleaning operation time, reducing purchase and use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

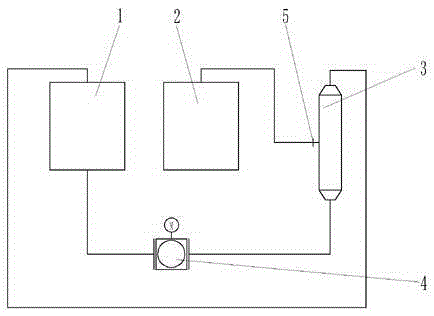

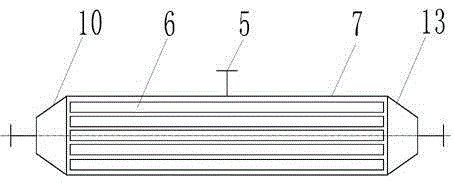

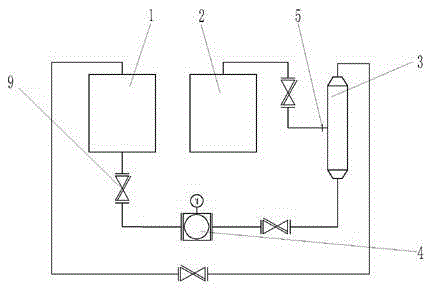

[0044] A sewage treatment system with an integral ceramic membrane filter, such as figure 1 , the sewage tank 1 is connected to the water pump 4 through the pipeline, the water pump 4 is connected to the sewage inlet of one or more integral ceramic membrane filters 3 through the pipeline, and the sewage outlet of the integral ceramic membrane filter 3 is connected to the sewage tank through the pipeline 1 connection, the clean water outlet 5 of the integral ceramic membrane filter 3 is connected with the clean water tank 2 through a pipeline, refer to figure 2 The ceramic membrane filter 3 is that the ceramic membrane tube 6 is arranged in the sealed housing 7, and the ceramic membrane tube 6 can be arranged horizontally, obliquely, shaped or vertically in the sealed housing 7 according to the needs, and the two ends of the sealed housing 7 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com