A trailer combined hanging basket structure and construction method

A combined tow-hoisting and suspension technology, applied in the erection/assembly of bridges, bridges, buildings, etc., can solve problems such as increasing the difficulty of construction and potential safety hazards, inability to apply cross-river bridge engineering, and difficulty in installing steel webs, etc. Achieve the effect of improving stability and safety, reasonable force, improving accuracy and fine-tuning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

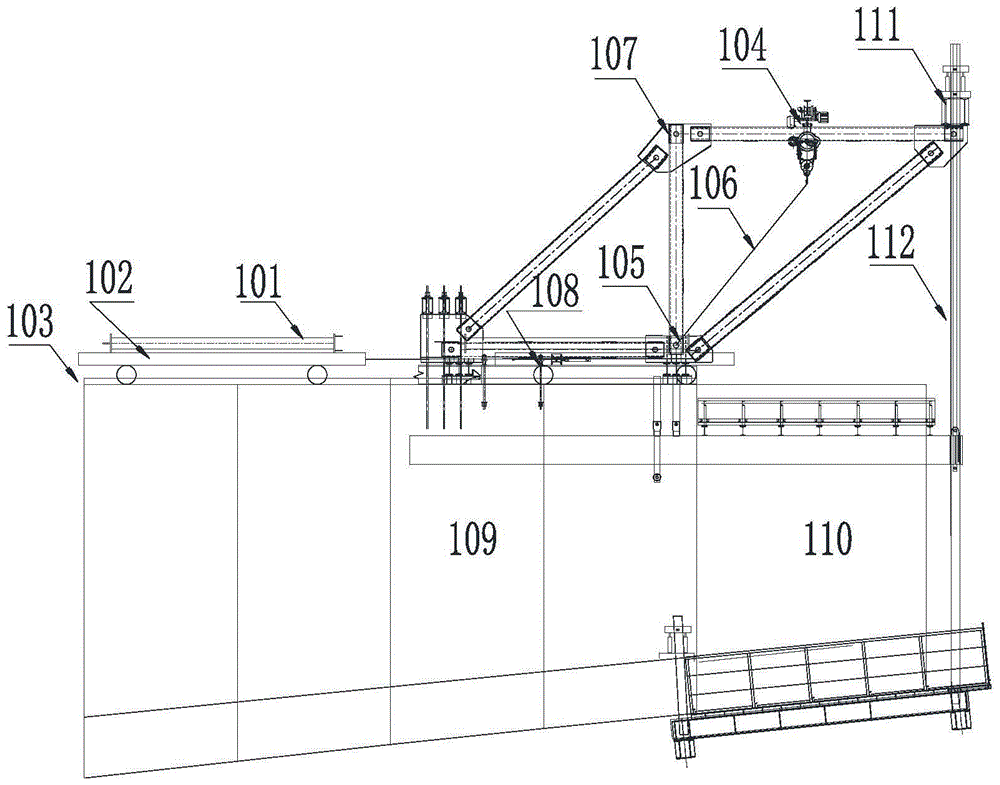

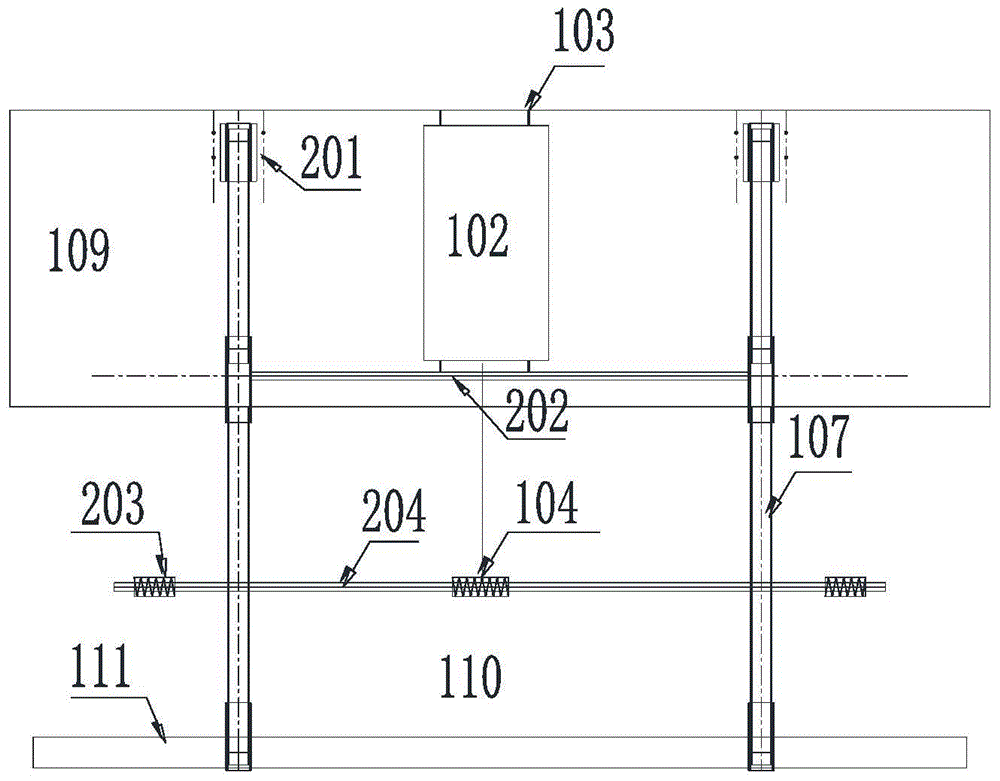

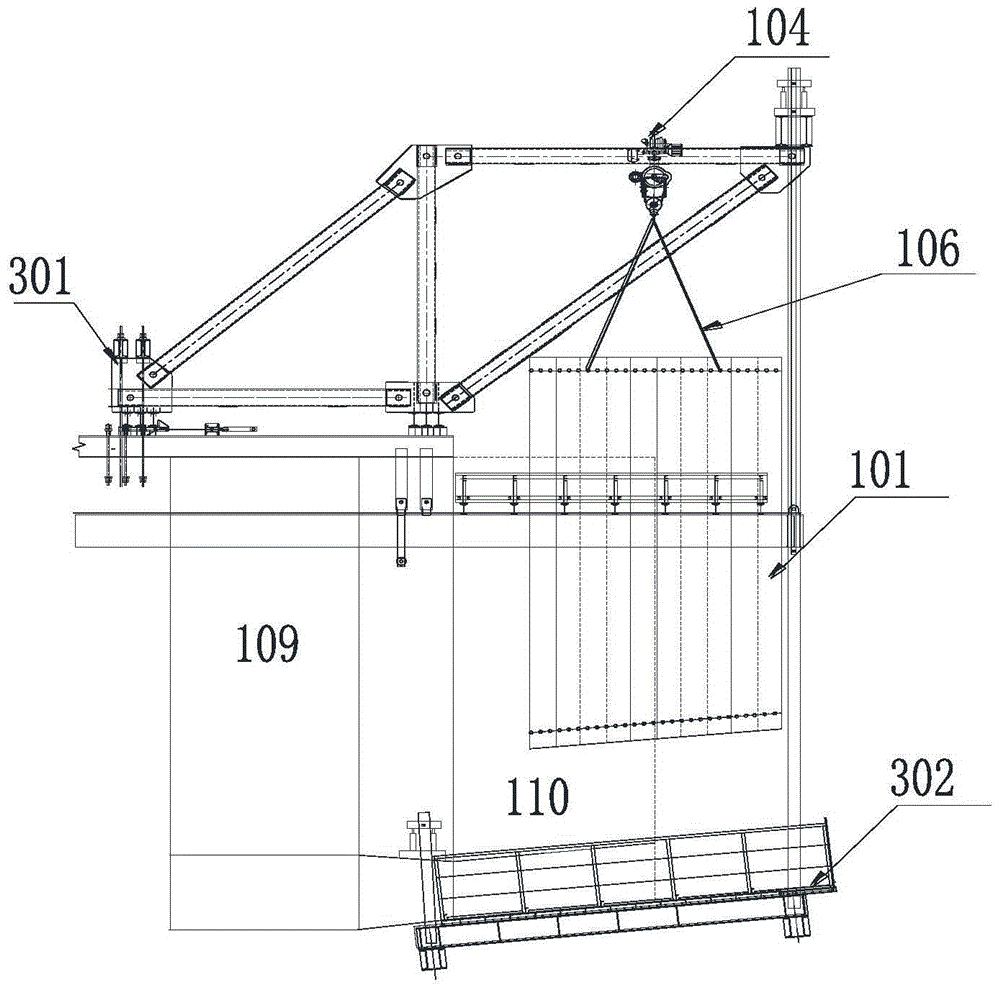

[0042] The invention mainly consists of a transport system, a hoisting system, and a hanging basket system. The transportation system is installed on the poured beam section and connected with the hoisting system, which can realize the bridge deck hauling of the corrugated steel web; The guide beam is transferred to the main truss of the hanging basket, and the hoisting and installation of the steel web is completed through three steel wire ropes and three electric hoists installed on the horizontal load-bearing guide beam; the hanging basket system is anchored to the poured beam section 109, and the The function is to bear all construction loads and complete the cantilever pouring construction process of the beam section 110 to be poured.

[0043] combine figure 1 , figure 2As shown, the transportation system includes a pallet tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com