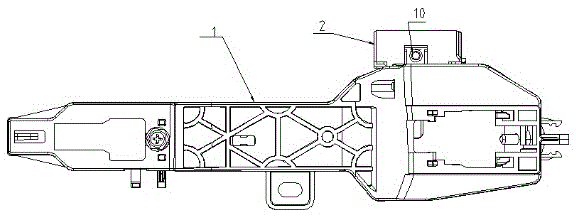

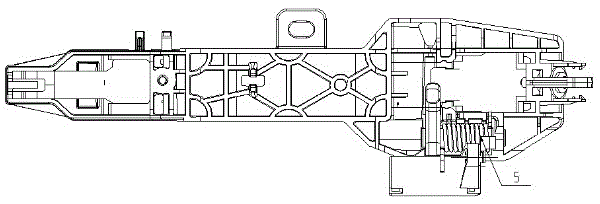

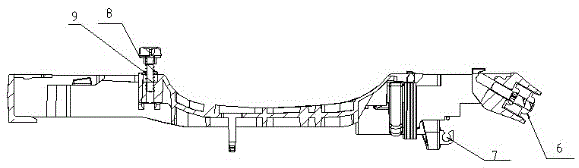

Front door outwards-opening handle support assembly

A technology for door opening handle and bracket assembly, which is applied in the field of auto parts and equipment, can solve the problems that the surface of the bracket body is easy to cause wear, abnormal noise, and the design quality affects the appearance of the car body, etc., and achieves improved appearance quality, simple structure, and fixed high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0017] Specific implementation method: during installation, the bracket body 1 is fixed by the bracket fixing screw 8, and the bracket fixing screw bushing 9 is installed under the bracket fixing screw 8 to prevent the bracket fixing screw from loosening, and then the handle cover fixing screw 6 is installed Strong, by pulling the torsion spring 5, driving the rotating shaft 4, dialing the control lever 7, and pulling the handle, the present invention installs the bracket fixing screw 8 in the bracket body 1 for fixing the bracket body 1, avoiding the scattering of the bracket body 1, The setting of the felt pad 11 effectively plays the role of shockproof and liner. The present invention is simple in structure, easy to use, high in fixing strength, good in effect, good in stability, and improves the appearance quality of the vehicle.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com