Method for reducing CO<2> flooding minimum miscible pressure

A carbon dioxide, miscible pressure technology, applied in earthwork drilling, production fluids, wellbore/well components, etc., can solve problems such as the impact of oil displacement effect, and achieve the effect of low cost and low consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

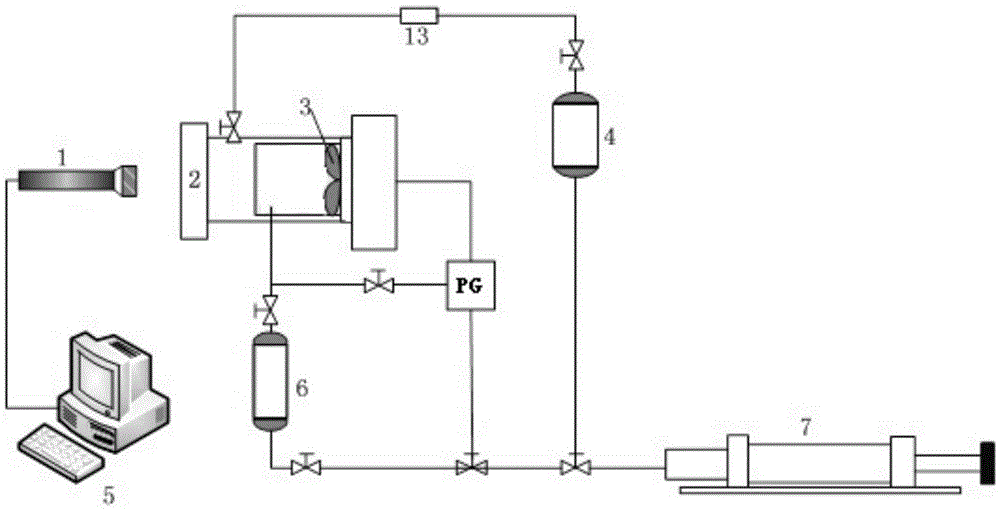

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a method for reducing the minimum miscible pressure of carbon dioxide flooding, the method is to 2 During miscible flooding, the mixed reducer I was dissolved in CO 2 in, with CO 2 At the same time, it is injected into the formation and mixed with the crude oil in the formation.

[0029] Wherein, the demixing agent I is a mixture of propanol, butanol and ethylenediamine, and the volume ratio of propanol, butanol and ethylenediamine in the mixture is 4:5:1. The injection volume of downmixing agent is CO 2 3.0% of mass.

[0030] The crude oil is Shengli crude oil, and the temperature of the crude oil is 60°C.

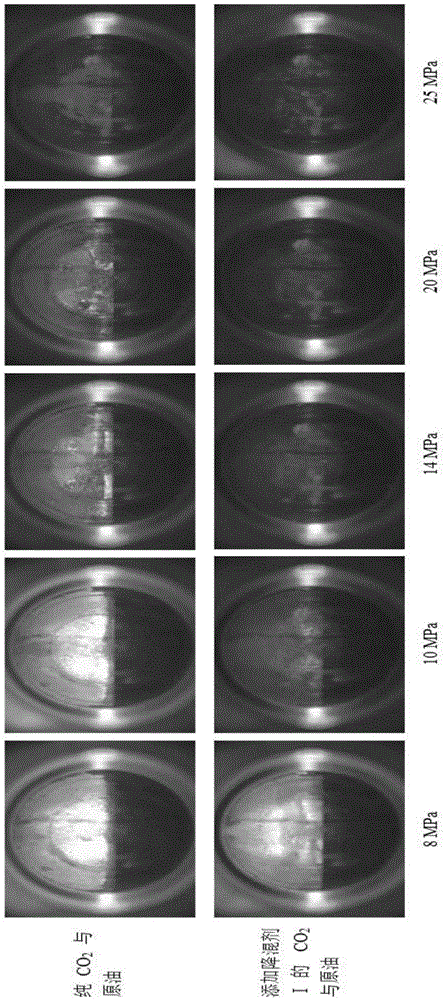

[0031] The method of reducing the minimum miscibility pressure of carbon dioxide flooding in this example is experimentally verified by observing the CO 2 State of crude oil and CO with demixing agent Ⅰ 2 The change trend of the state of crude oil and the pressure with the pressure, to prove that the addition of demixing agent Ⅰ can r...

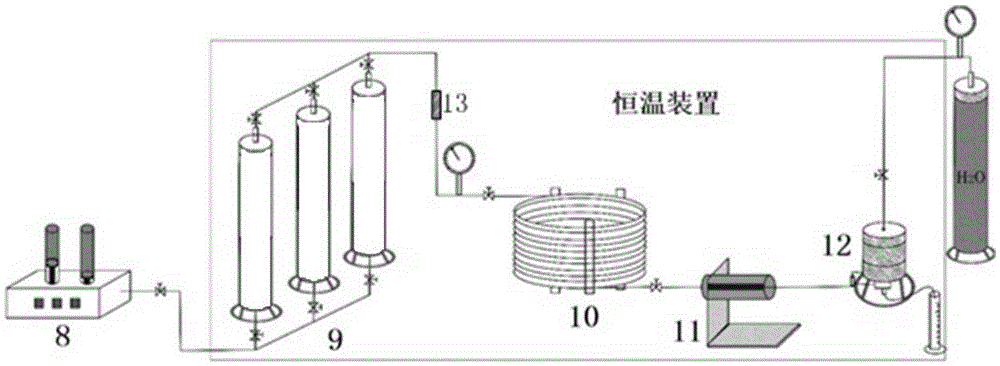

Embodiment 2

[0045] This embodiment provides a method for reducing the minimum miscible pressure of carbon dioxide flooding, the method is to 2 During miscible flooding, the mixed reducer II was dissolved in CO 2 in, with CO 2 At the same time, it is injected into the formation and mixed with the crude oil in the formation.

[0046] Wherein, the demixing agent II is a mixture of methanol and ethylene glycol, and the volume ratio of methanol and ethylene glycol in the mixture is 7:3. The injection volume of downmixing agent is CO 2 3.0% of mass.

[0047] The crude oil is Jidong crude oil, and the temperature of the crude oil is 80°C.

[0048] Experimental verification is carried out on the method of reducing the minimum miscible pressure of carbon dioxide flooding in this embodiment:

[0049] Use a 5mL syringe to measure 5mL of Jidong crude oil at a temperature of 80°C, and inject it into the micro-injection pump of the high-pressure interfacial tensiometer, and set the temperature of ...

Embodiment 3

[0057] This embodiment provides a method for reducing the minimum miscible pressure of carbon dioxide flooding, the method is to 2 During miscible flooding, dissolve the mixed reducer III in CO 2 in, with CO 2 At the same time, it is injected into the formation and mixed with the crude oil in the formation.

[0058] Wherein, the demixing agent III is a mixture of ethanol, butanol and ethylenediamine, and the volume ratio of ethanol, butanol and ethylenediamine in the mixture is 5:3:2. The injection volume of downmixing agent is CO 2 4.0% of mass.

[0059] The crude oil is Jidong crude oil, and the temperature of the crude oil is 70°C.

[0060] The method of reducing the minimum miscible pressure of carbon dioxide flooding in this example is experimentally verified, and the CO 2 Oil displacement minimum miscible pressure and CO 2 The minimum miscibility pressure of oil displacement, thus proving that the addition of demixing agent can reduce CO 2 Oil displacement minimum...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap