Single-frame cold rolling force model and front sliding model debugging method

A technology of cold rolling and rolling force, which is applied in the field of single-stand cold rolling rolling force model and forward slip model debugging, and can solve the problems of cumbersome calculation process and long calculation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to enable those skilled in the technical field to which the application belongs to understand the application more clearly, the technical solutions of the application will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

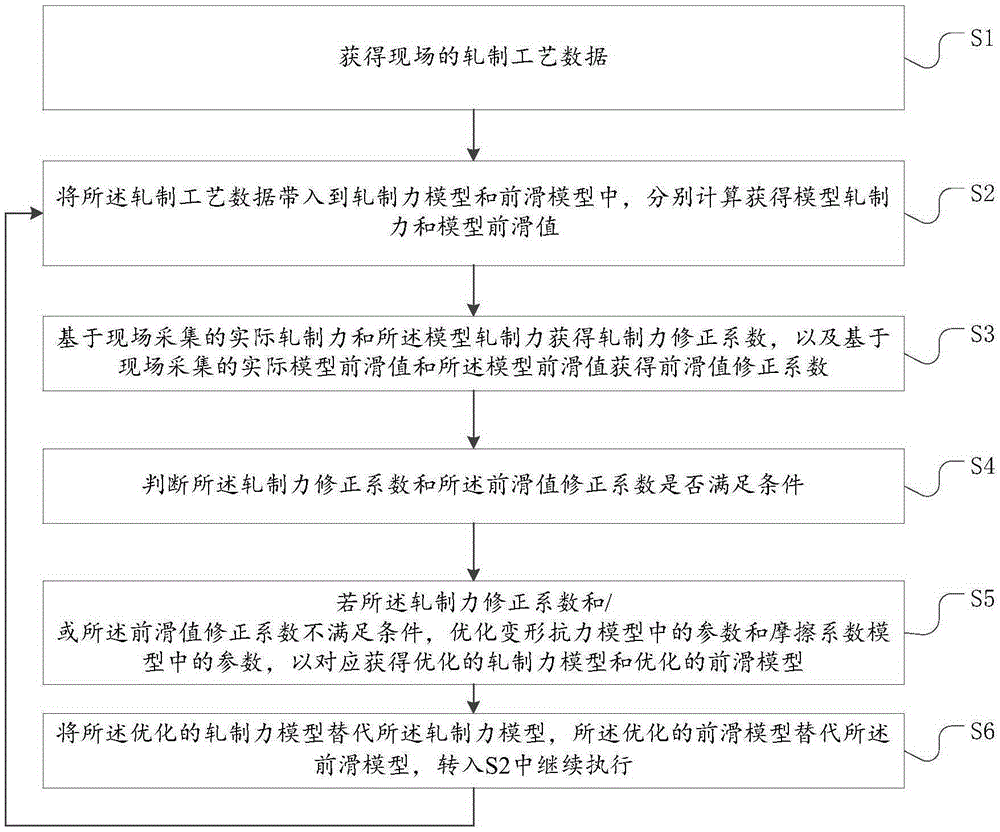

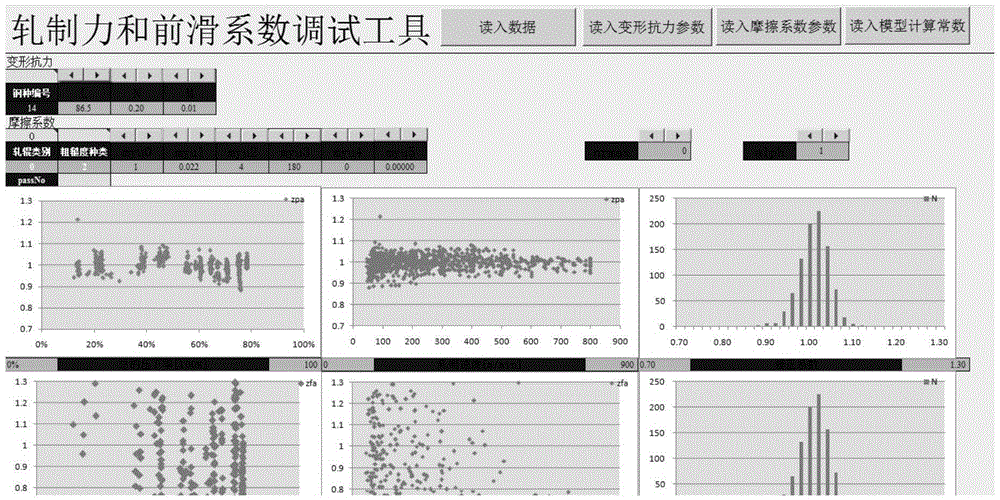

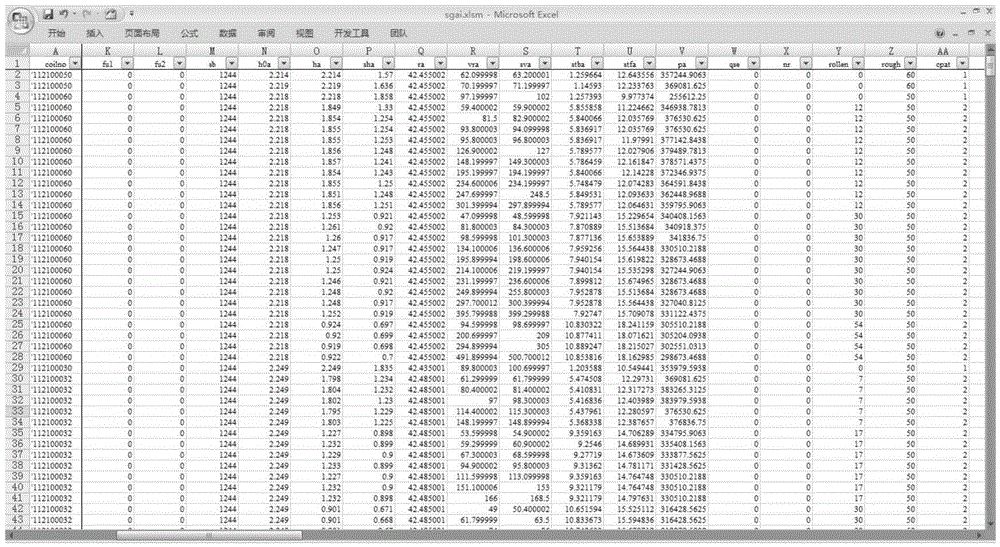

[0047] The purpose of the present invention is to establish a single-stand cold rolling rolling force model and forward sliding model debugging method, according to the actual data under normal working conditions, by adjusting the parameters of the deformation resistance model and the parameters of the friction coefficient model, the deformation resistance calculation can be improved Accuracy and calculation accuracy of friction coefficient, thereby improving the calculation accuracy of rolling force and forward slip setting. In addition, according to the idea, the present invention can establish a set of devices that can calculate quickly with parameter optimization and graphically displ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com