Pipe-supplying method and pipe-supplying apparatus for material pipes for integrated circuit packaging equipment

A technology for integrated circuits and packaging equipment, which is applied in the field of tube supply methods and tube supply devices in integrated circuit packaging equipment, and can solve problems such as error-prone, high labor costs, and manual tube arrangement that cannot keep up with the speed, and achieve Fast piping speed, manpower saving and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] A pipe supply method for a material pipe in integrated circuit packaging equipment, comprising the following steps:

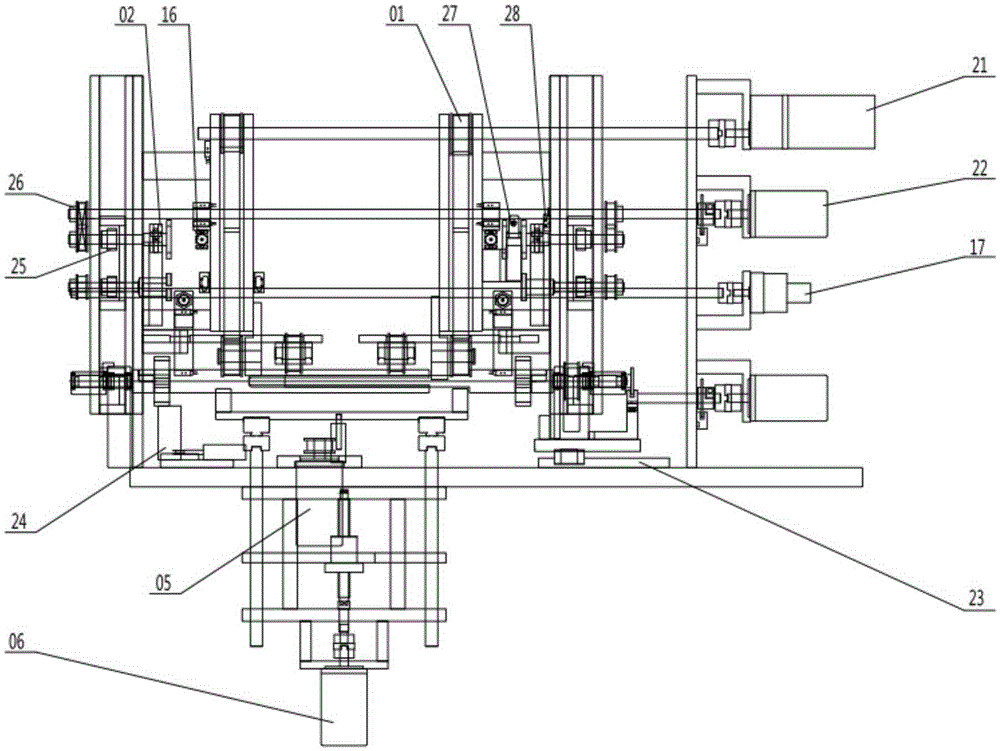

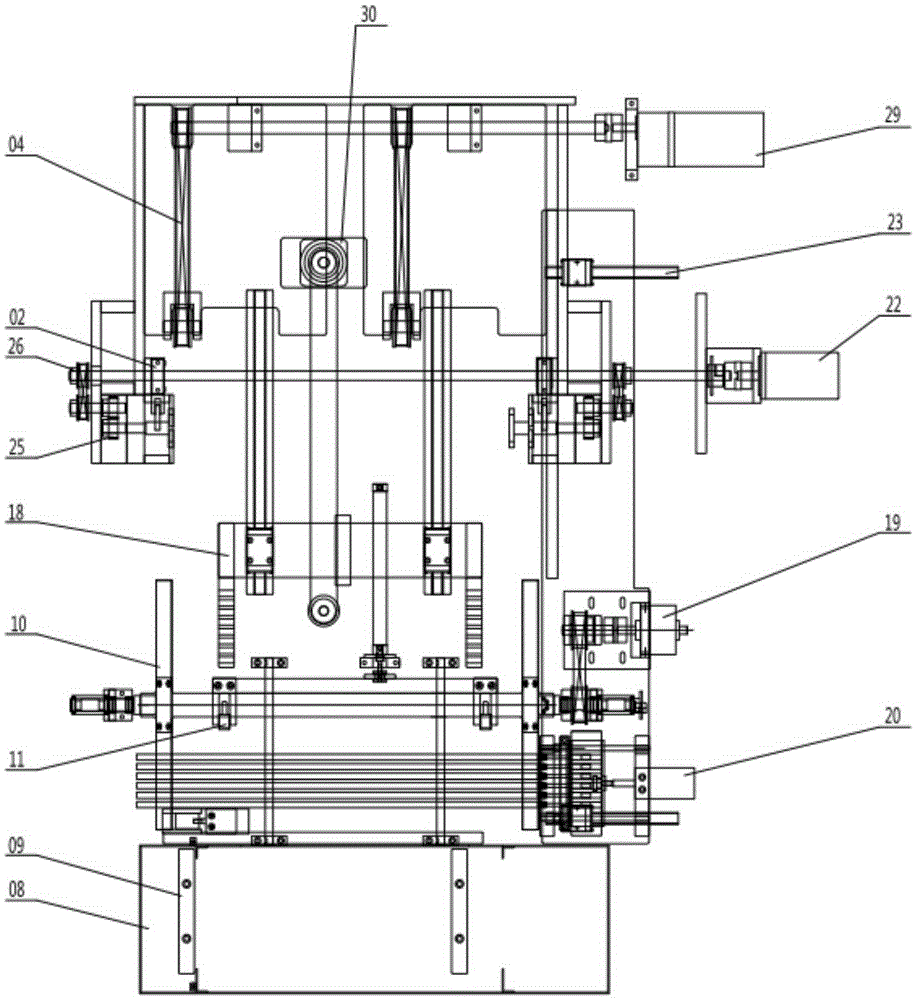

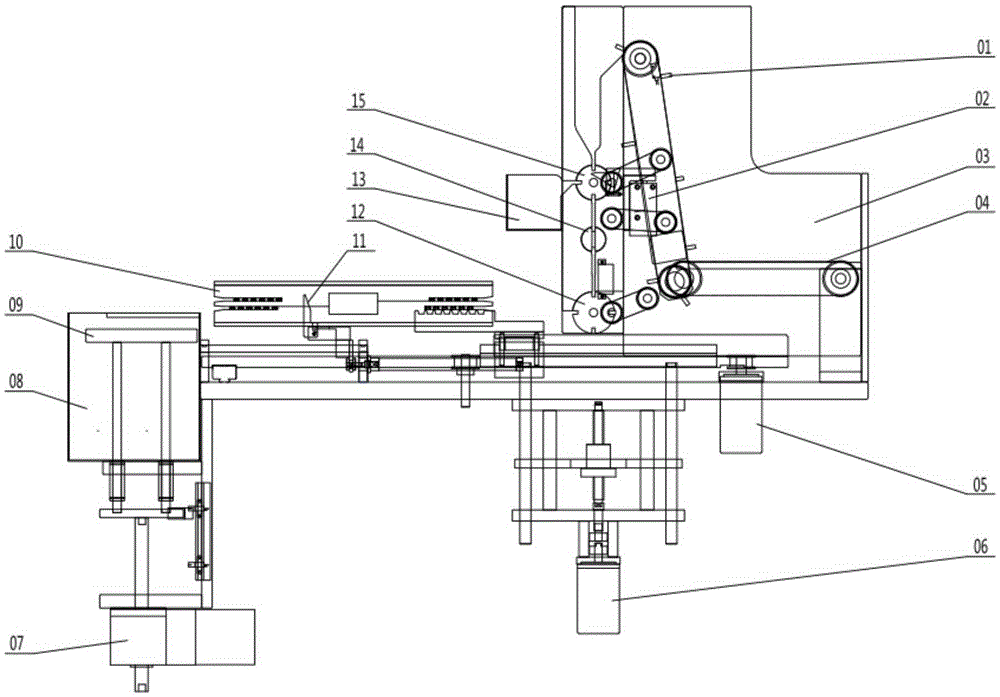

[0032] 1) Put batches of material tubes into the material tube placement tank 03, and move them back and forth by the material tube horizontal finishing belt 04, and the sorted material tubes are carried upward by the material tube upper and lower conveying belt 01, and fall to the material tube direction detection turntable In the material tube groove of 15, if it cannot fall and the material tube is piled up, then the material tube is knocked upward by the cylinder 02 to make it fall, and in the material tube direction detection turntable 15, the rubber plug is used to detect the cylinder 28 and the material tube. The tube direction detection cylinder 27 detects the presence or absence of a rubber plug and the direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com