Pipe supply method and pipe supply device for charge pipes in integrated circuit packaging equipment

A technology for integrated circuits and packaging equipment, which is applied in the field of a pipe supply method and a pipe supply device for a material pipe in an integrated circuit packaging equipment, can solve the problem of difficulty in adapting to different product pipe entry methods, error-prone, and manual pipe arrangement cannot keep up with the speed. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

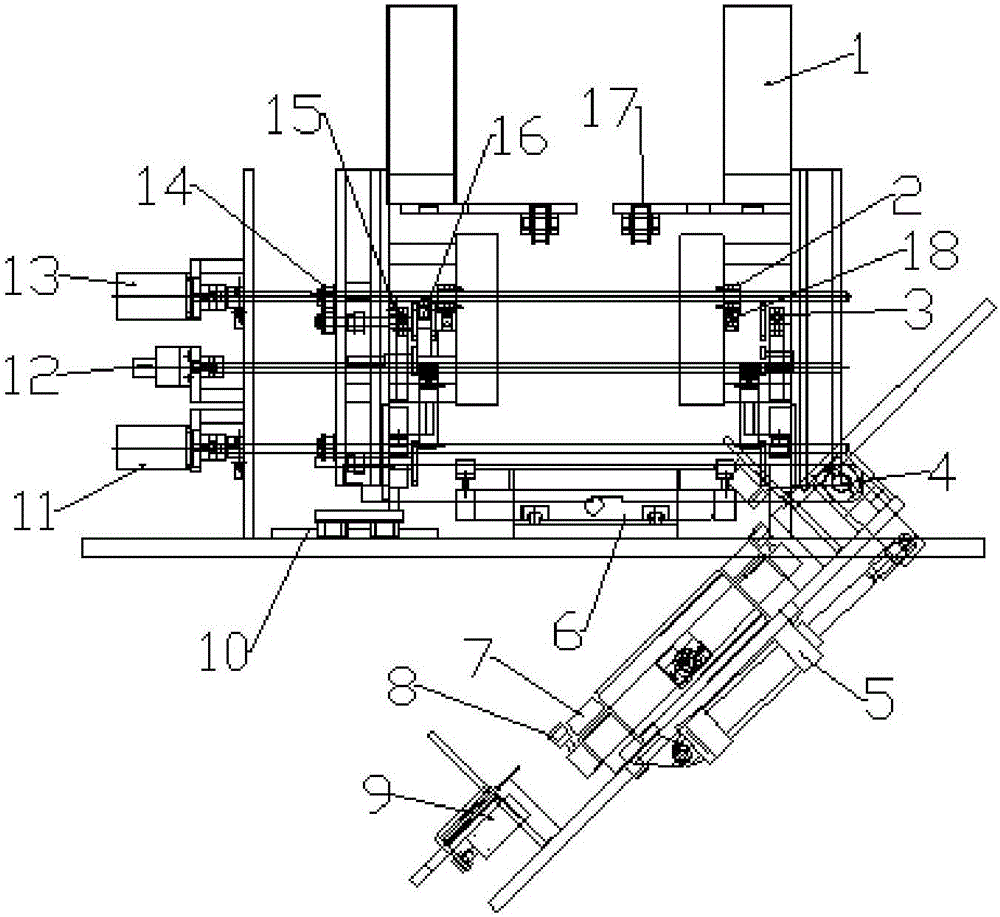

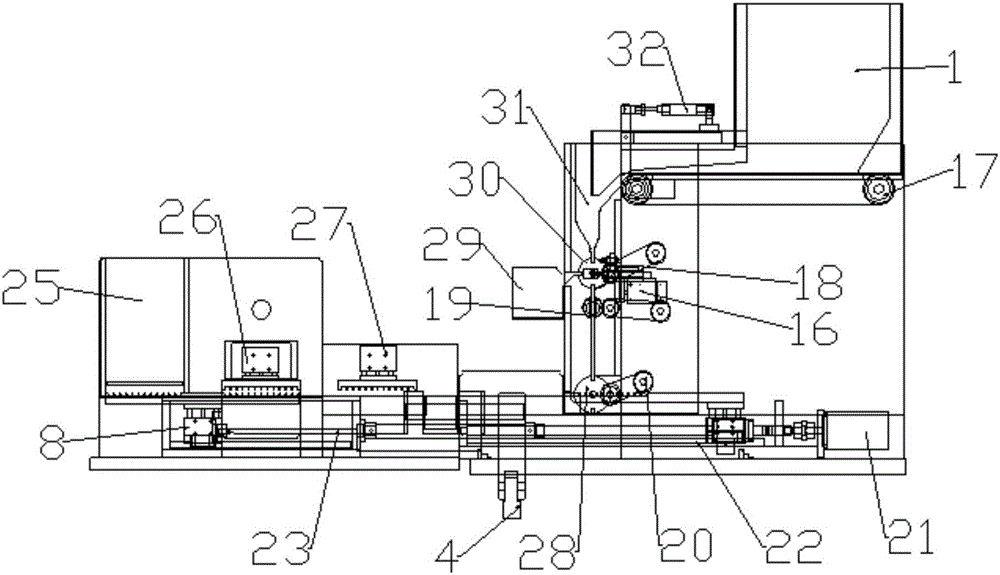

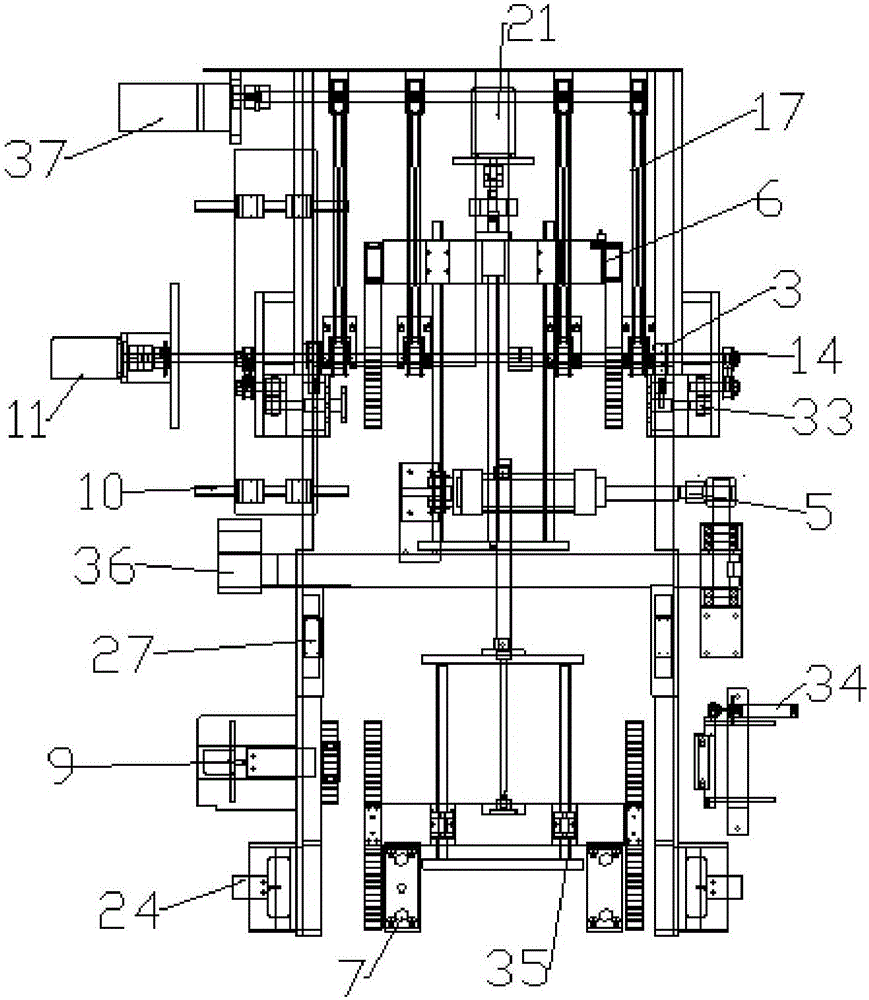

[0021] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0022] Figure 1-Figure 3 The markings in the center include: material tube placement groove 1, material tube detection sensor 2, material tube finishing cylinder 3, material tube swing mechanism 4, material tube swing cylinder 5, material tube transmission mechanism 6, material receiving jacking cylinder 7, material tube transmission Lifting cylinder 8, material tube propulsion cylinder 9, material tube length adjustment guide rail 10, material tube discharge motor 11, material tube turning cylinder 12, material tube sorting motor 13, belt transmission mechanism 14, rubber stopper detection sensor 15, material tube direction detection Cylinder 16, material tube finishing belt 17, material tube push-out cylinder without rubber plug 18, material tube turning mechanism 19, transmission belt 20, material tube transmission motor 21, material tube t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com