Burden distribution device of disc filter and method thereof

A disc filter and cloth device technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of unstable feeding, vacuum leakage of the filter, low liquid level, etc., to avoid a large amount of leakage, Easy-to-promote, simple-structured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

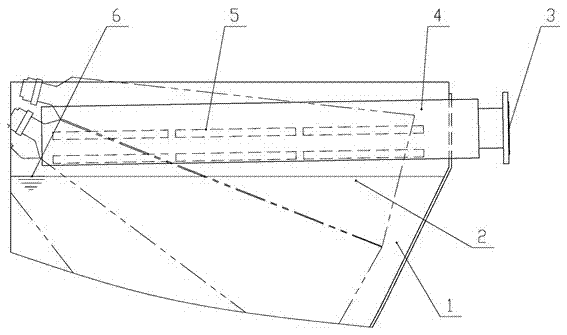

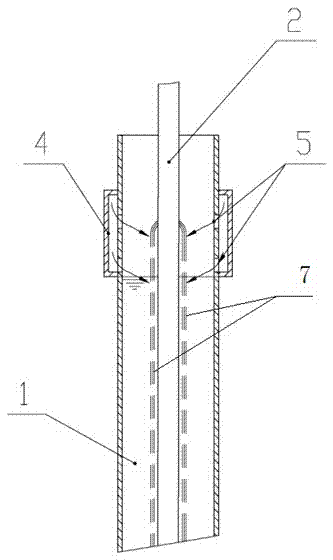

[0016] Such as figure 1 , 2 As shown, a distributing device of a disc filter is located at the feeding part of the tank body 1 of the disc filter, including: a distributing trough 5, a collecting box 4, a flange feeding port 3, and a fan-shaped plate 2. The flange feed inlet 3 on the tank body 1 communicates with several collection boxes 4 on the tank body 1, and the collection boxes 4 and the corresponding parts on the surface of the fan-shaped plate 2 are evenly distributed with distribution grooves 5.

[0017] A distributing method for a disc filter, the steps are as follows:

[0018] 1. Install a collection box 4 with the function of distributing material on the feeding part of the slurry tank body 1 of the disc filter;

[0019] 2. The feed slurry first enters the collection box 4 through the flange feed port 3, and when the slurry fills the collection box 4, the liquid slurry flows out through a number of evenly distributed distribution grooves 5 in the collection box 4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap