An electric kettle body automatic polishing feeding device

An automatic polishing and feeding device technology, which is applied in the direction of grinding drive device, surface polishing machine tool, grinding/polishing equipment, etc., to achieve the effect of simple structure, reduced labor intensity and good product consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

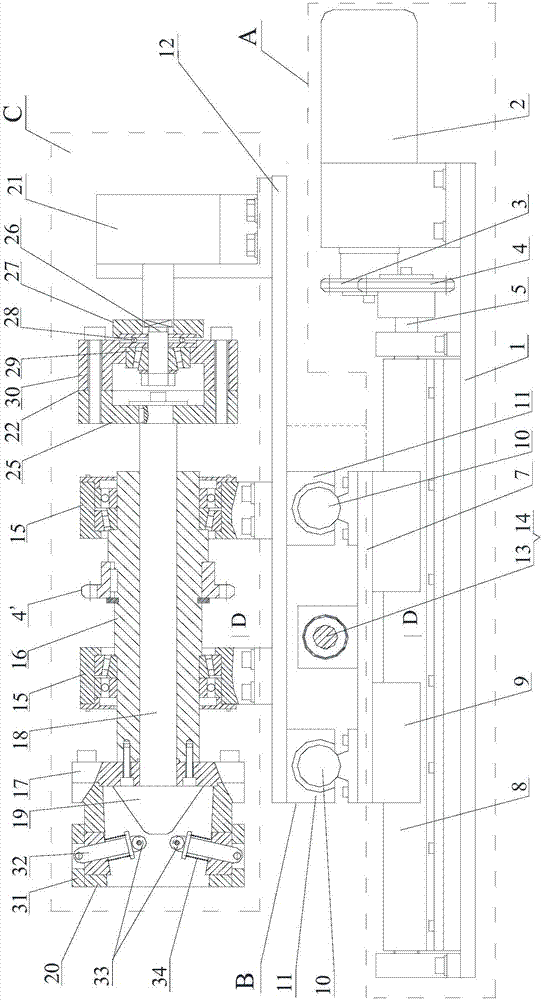

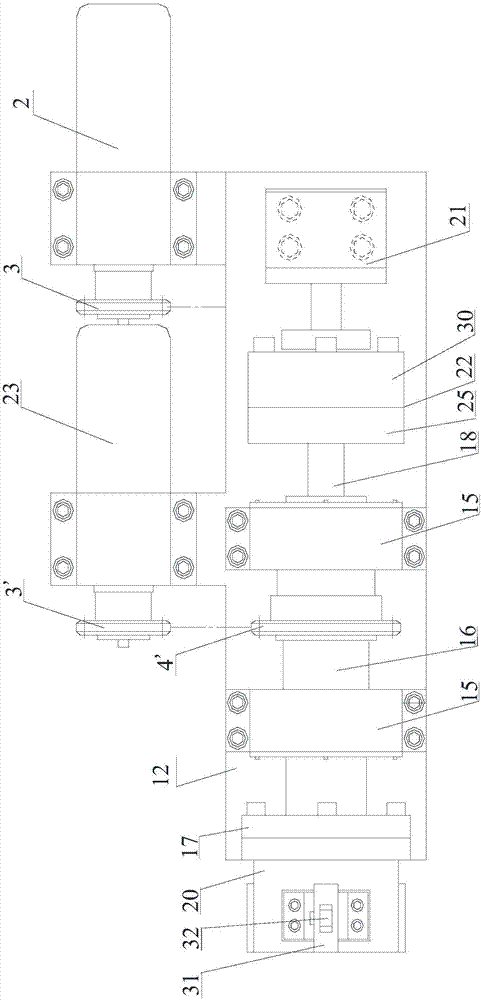

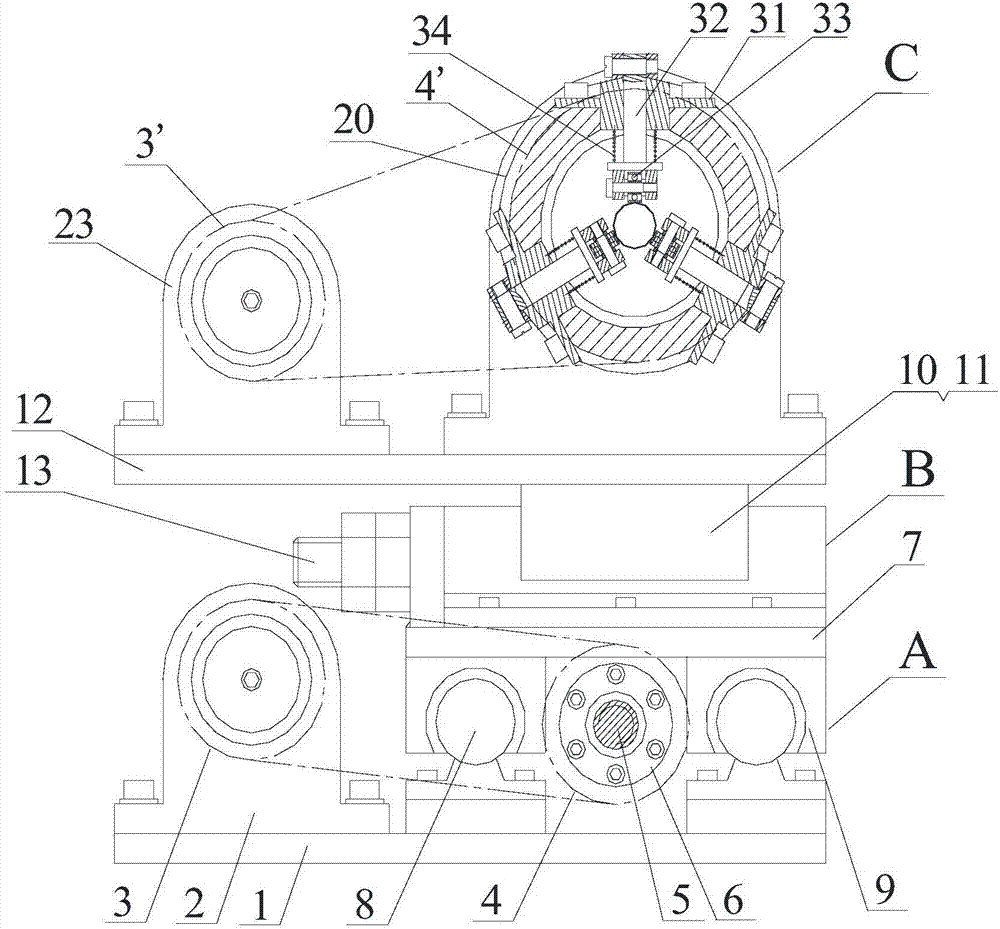

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] An electric kettle body automatic polishing feeding device, such as figure 1 , figure 2 , image 3 and Figure 4 As shown: the device is composed of a longitudinal feed mechanism A, a lateral feed adaptive mechanism B, and a clamping and rotating mechanism C.

[0028] The longitudinal feed mechanism A of the present invention comprises a longitudinal feed motor 2 mounted on the device base 1 and a first driving sprocket 3 driven by the longitudinal feed motor 2, and the first driving sprocket 3 is driven by a transmission chain and a first driving sprocket. A driven sprocket 4 is connected to a lead screw drive pair 5 installed on the side, and a lead screw nut 6 on the lead screw drive pair 5 is connected and fixed with two longitudinal linear guide rails 8 and four longitudinal linear slide blocks 9 In the fixed plate 7, four lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com