Automatic pipe billet polishing machine

A polishing machine and tube blank technology, applied in the field of mechanical processing, can solve the problems of waste of resources, low labor efficiency, and tube blank throwing, etc., and achieve the effects of saving labor, solving a large amount of grinding work, and improving labor productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

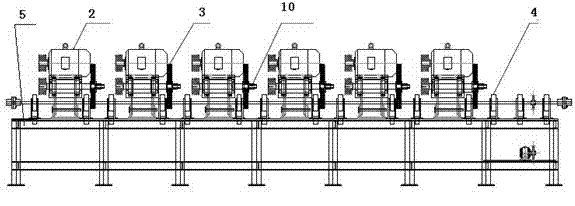

[0013] The overall structure of the automatic tube blank polishing machine in the embodiment of the present invention is as attached figure 1 As shown, it mainly includes a bracket 5 and a number of polishing machines fixed on the bracket 5 and conveying rollers 4. It is characterized in that the polishing machine includes a throwing disc free swing device and a pressure balance device 7.

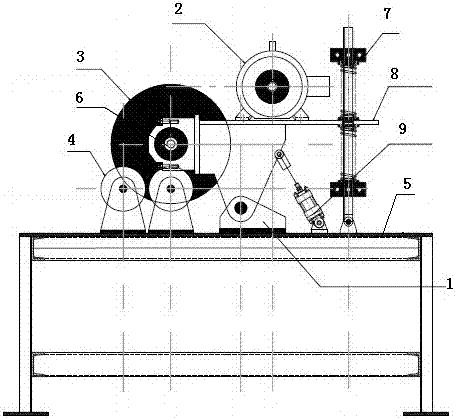

[0014] The throwing plate free swing device is attached figure 2 As shown, it mainly includes an inverted triangular throwing plate and a front and rear swing base 1 fixed on the bracket 5. The lower end of the inverted triangle throwing plate is movably connected with the front and rear swinging base 1; There is a pneumatic booster system9.

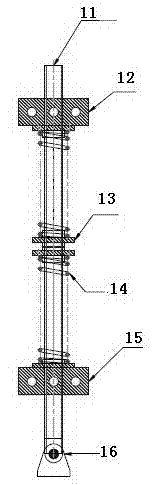

[0015] Pressure balance device 7 as attached image 3 As shown, it mainly includes a fixed base 16 fixed on the support 5 and an adjusting screw 11, the fixed base 16 is movably connected with the lower end of the adjusting screw 11; The bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com