Stainless steel tool surface treatment method

A surface treatment, stainless steel technology, used in manufacturing tools, other manufacturing equipment/tools, grinders, etc., can solve the problems of complex structure of polishing equipment and slow polishing rate, achieve polishing and transmission automation, reduce workload, and increase polishing effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

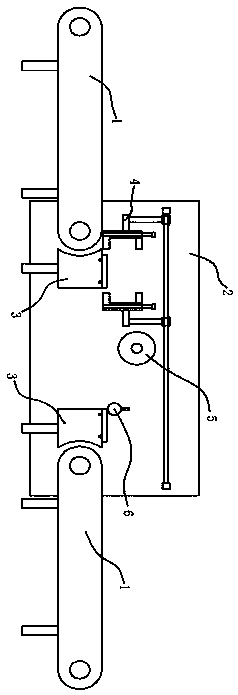

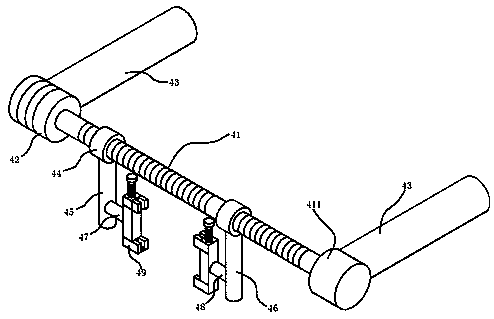

[0030] refer to Figure 1-6 , a method for surface treatment of stainless steel knives, comprising two conveyor belts 1, an operation box 2 is arranged between the two conveyor belts 1, and two turning structures 3 are symmetrically arranged in the operation box 2, and the operation box A clamping structure 4 is provided on the side plate of the operation box 2, and a polishing structure 5 is symmetrically provided on the two side plates of the operation box 2, and a pushing structure 6 is provided on one side of the polishing structure 5.

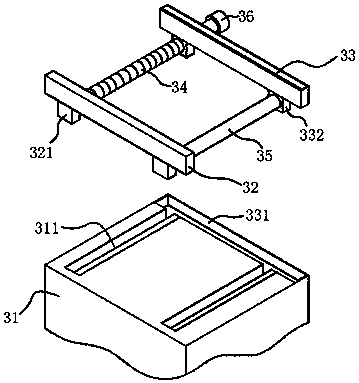

[0031] Refer to attached Figure 1-2 The overturning structure 3 includes an overturning platform 31, one side of the overturning platform 31 is fixedly connected to a limit plate 32, and the other side is slidably connected to a first electric telescopic plate 33, and the first electric telescopic plate 33 can be retracted to a concave position. slot 331.

[0032] The bottom of the limiting plate 32 is fixedly connected to a plurality o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com