Robot system and method for picking workpiece

A robot system and robot technology, applied in the direction of robots, conveyor objects, general control systems, etc., can solve the problems of reduced workpiece conveying efficiency and longer robot movement distance, and achieve the effect of efficient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, embodiments of the robot system and the workpiece picking method disclosed in the present application will be described in detail with reference to the drawings. In addition, this invention is not limited to embodiment shown below.

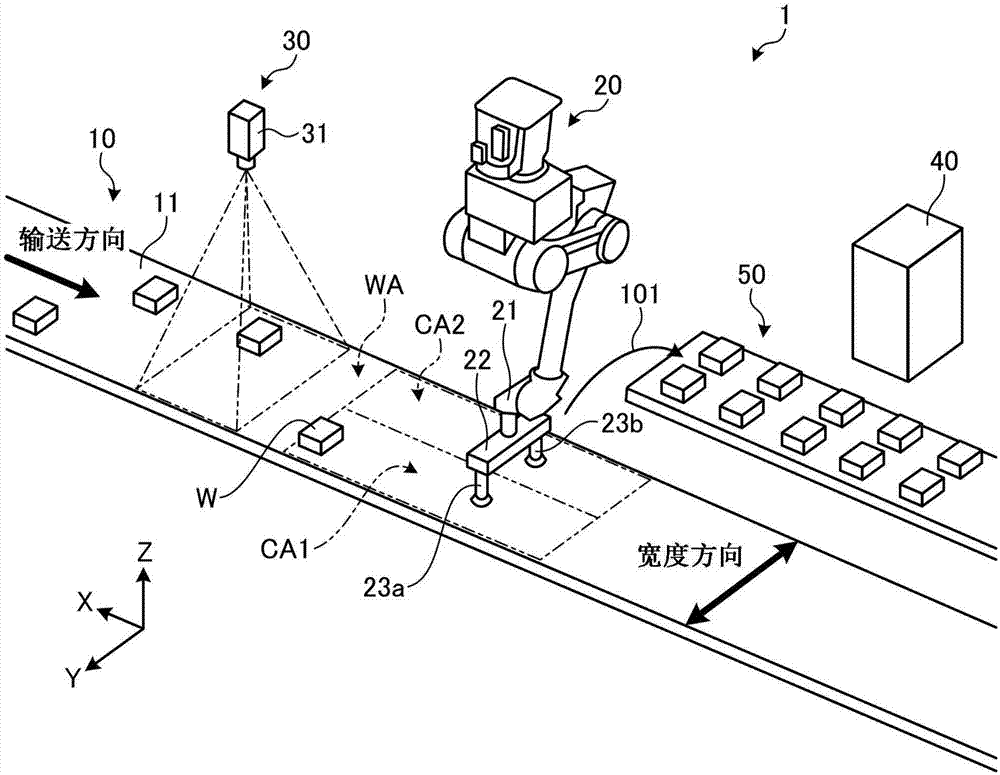

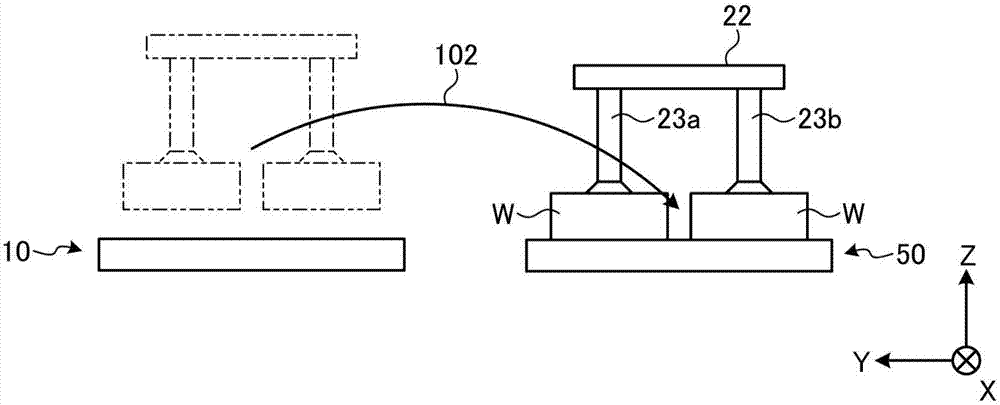

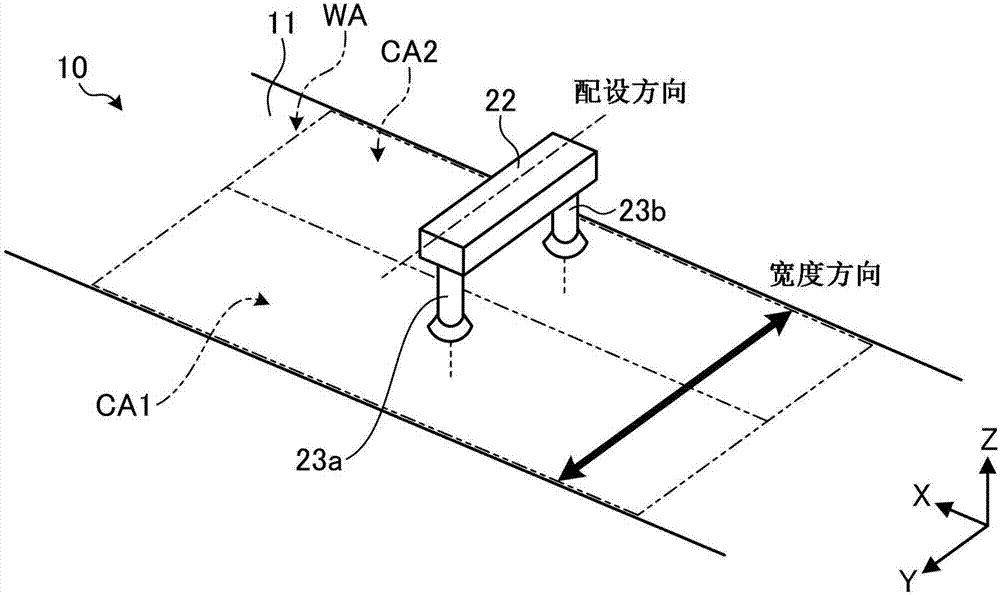

[0028] First, use Figure 1A ~ Figure 1C The outline of the robot system 1 according to the embodiment will be described. Figure 1A It is a perspective schematic diagram which shows the arrangement|positioning structure of the robot system 1 of embodiment. Figure 1B is a schematic diagram showing one transfer operation. Figure 1C is a schematic diagram showing the arrangement relationship between the robot hand in the basic posture and the divided regions.

[0029] In addition, in Figure 1A In FIG. 2 , in order to make the description easier to understand, the figure shows a three-dimensional orthogonal coordinate system including the Z-axis whose vertical direction is positive. This orthogonal coordinate system may also...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap