Novel environment-friendly geotextile material having soil fixation, water seepage and load bearing functions as well as preparation method of geotextile material

A technology of geotechnical materials and color masterbatches, applied in soil protection, chemical instruments and methods, infrastructure engineering, etc., can solve the problems of inability to waterproof, long construction period, large investment, etc., and achieve the effect of excellent high and low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

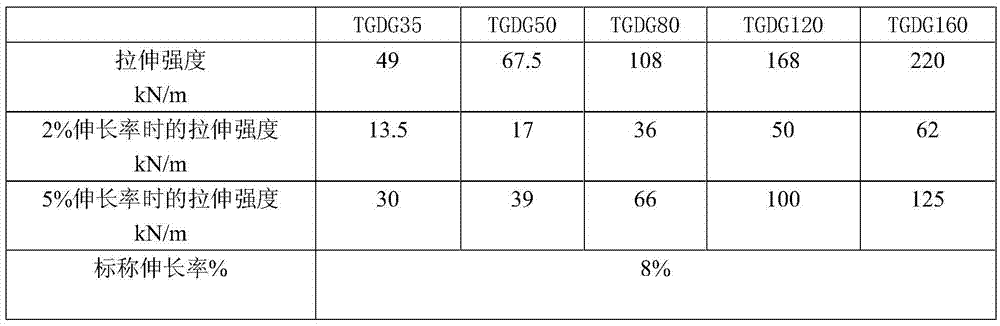

Image

Examples

Embodiment 1

[0022] A geotechnical material, its composition in parts by weight is: 5-20 parts of A-random polypropylene, 80-90 parts of B, 10-30 parts of C, and 2-10 parts of D-color masterbatch. B is glass fiber modified polypropylene or carbon fiber modified polypropylene, and C is low pressure polyethylene. In the glass fiber modified polypropylene, the glass fiber is 10-30%, and the carbon fiber in the carbon fiber modified polypropylene is 10-30%. The preparation method is as follows:

[0023] (1) Add D to A, mix well, and put it into the A extruder for kneading and plasticizing; B is put into the hopper of the B extruder for kneading and plasticizing; C is put into the hopper of the C extruder for kneading and plasticizing Extrusion; extrusion processing temperature is controlled at 160-280°C;

[0024] (2) Divide B extruded material and C extruded material obtained in step (1) into double-layer complexes of B and C through a distributor, and then enter a stacking machine to superi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com