Energy-saving eco-friendly novel automobile and motorcycle internal decorating material and manufacturing method thereof

A technology for interior materials and vehicles, applied in vehicle components, superstructure sub-assemblies, layered products, etc., can solve the problems of non-recyclability and odor of interior materials, and achieve the effect of excellent high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

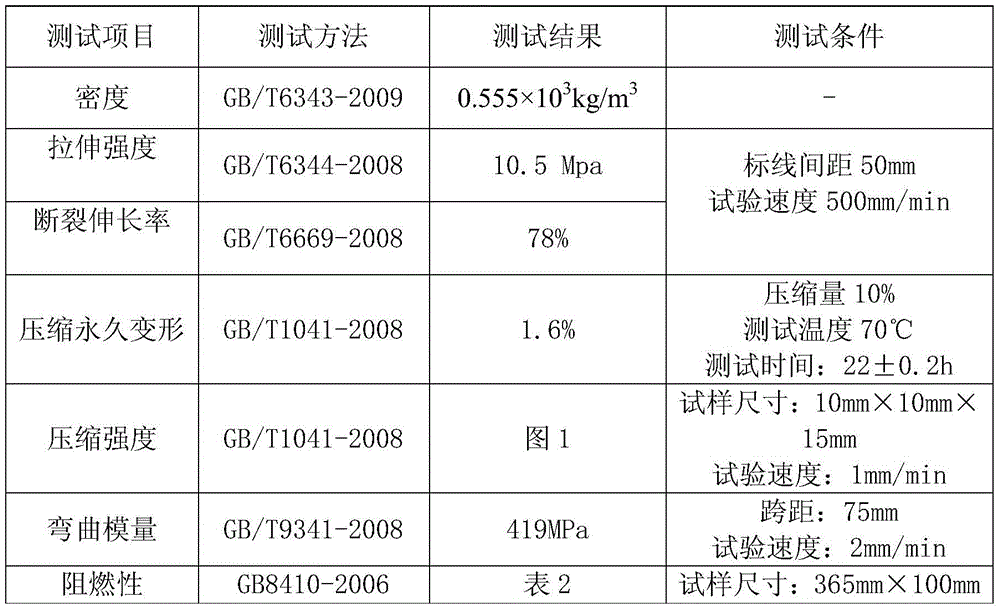

[0026] A vehicle interior material, which consists of the following components: A-5-10 parts of flame-retardant polypropylene, 80-90 parts of high-melt strength polypropylene, C-glass fiber reinforced polypropylene or calcium carbonate polypropylene 10- 30 parts, 3-5 parts of D-foaming agent, calculated in parts by weight. The glass fiber of the glass fiber polypropylene is 5wt%-30wt%, and the calcium carbonate of the calcium carbonate polypropylene is 5wt%-30wt%.

[0027] The preparation method comprises the following steps:

[0028] (1) Put the A-flame retardant polypropylene into the A extruder and extrude through mixing and plasticizing. The high melt strength polypropylene and foaming agent are mixed in proportion and then put into the hopper of the B extruder for mixing and plasticizing. Extrude, put C into the hopper of C extruder and extrude through kneading and plasticizing;

[0029] (2) Divide B extruded material and C extruded material obtained in step (1) into do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com