Spark detection device with self-cleaning function

A detection device and self-cleaning technology, applied in cleaning methods and appliances, fiber processing safety devices, cleaning methods using gas flow, etc., can solve problems such as difficult to get guarantees, fires, etc., to achieve accurate detection results and prevent fires , Improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

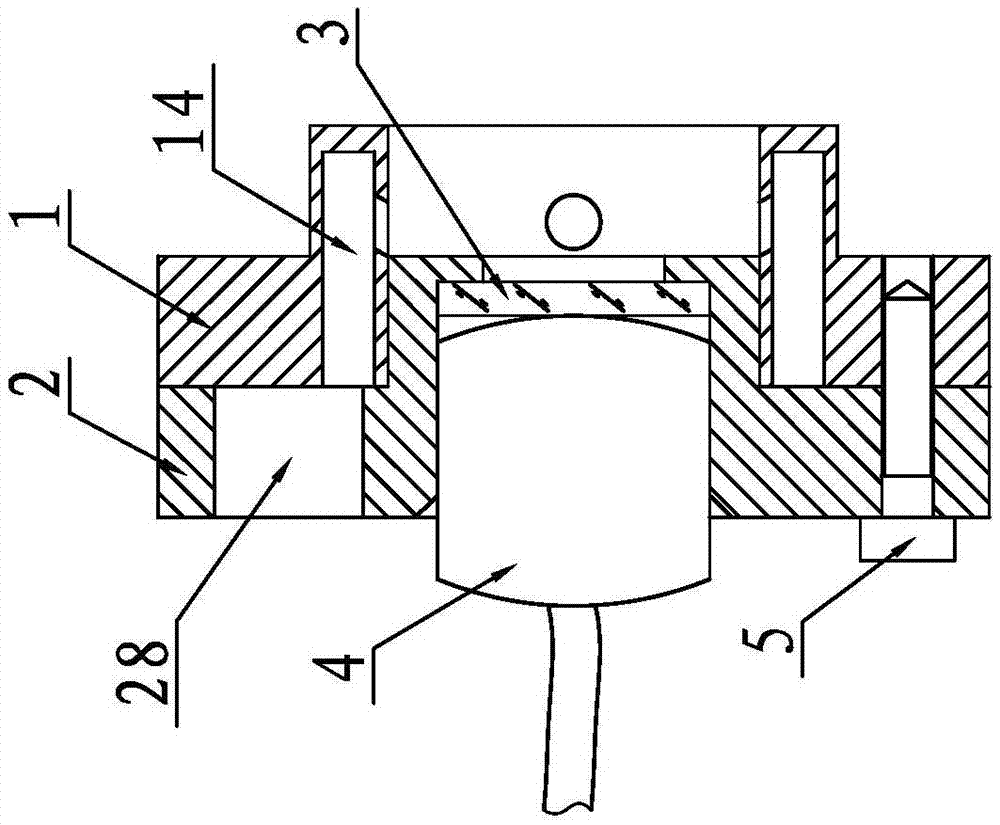

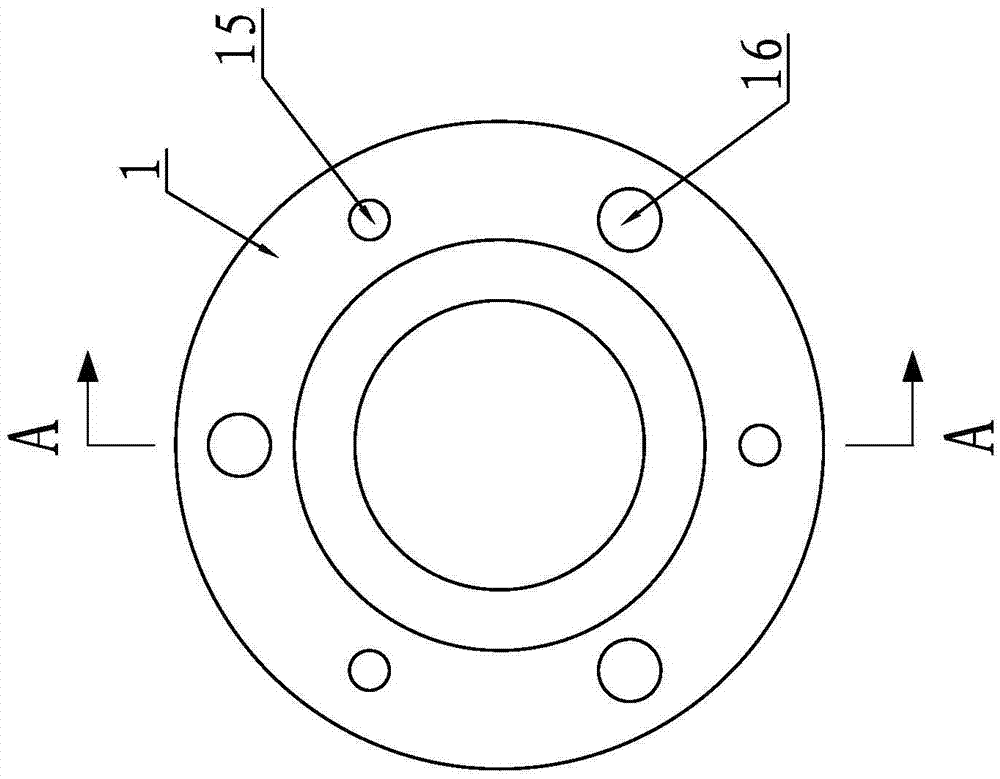

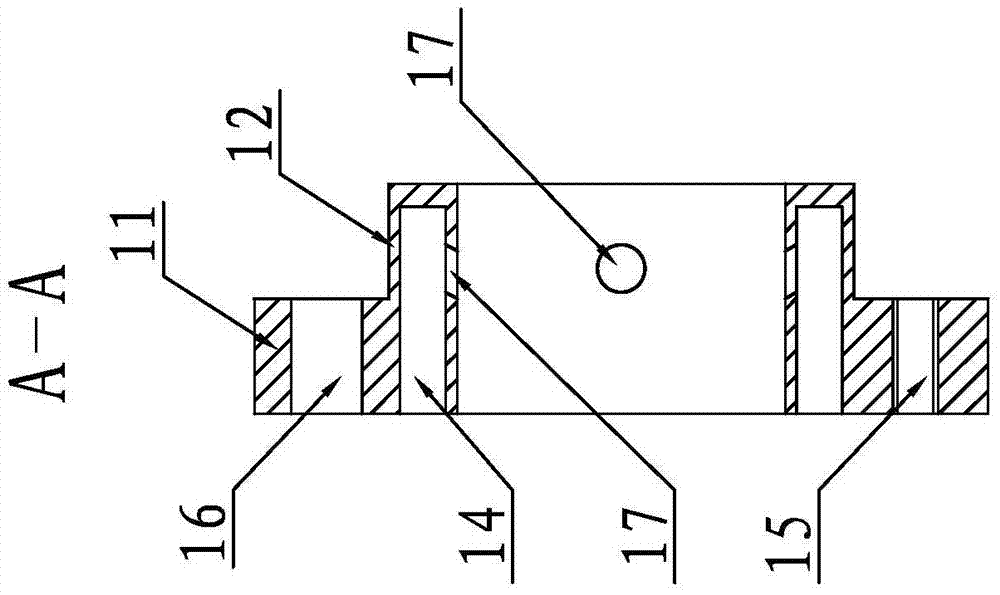

[0024] A spark detection device with self-cleaning function, such as Figure 1 to Figure 7 As shown, it includes an airway seat 1, a sensor mounting seat 2, a probe lens 3 and a sensor 4. Both the airway seat 1 and the sensor mounting seat 2 have a stepped sleeve structure, and the airway seat 1 includes an airway connecting flange 11 , installation shoulder 12, positioning center hole 13, annular air passage 14, connecting screw hole 15, connecting through hole 16 and self-cleaning air hole 17, air passage connecting flange 11 and installation shoulder 12 are coaxially arranged, wherein, positioning The central hole 13 and the annular air channel 14 are arranged on the combination of the air channel connecting flange 11 and the mounting shoulder 12 from the outside to the inside, and there are three equally spaced apart on the air channel connecting flange 11 of the air channel seat 1 . Connect the screw hole 15 and three connecting through holes 16, the self-cleaning air hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com