An excavating device adapted to the narrow working face of railway tunnels

A technology for excavating devices and working surfaces, which is applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of difficulty in guaranteeing operation quality, poor handling environment, and low operation efficiency, and achieves the goal of reducing labor intensity and improving excavation efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 11

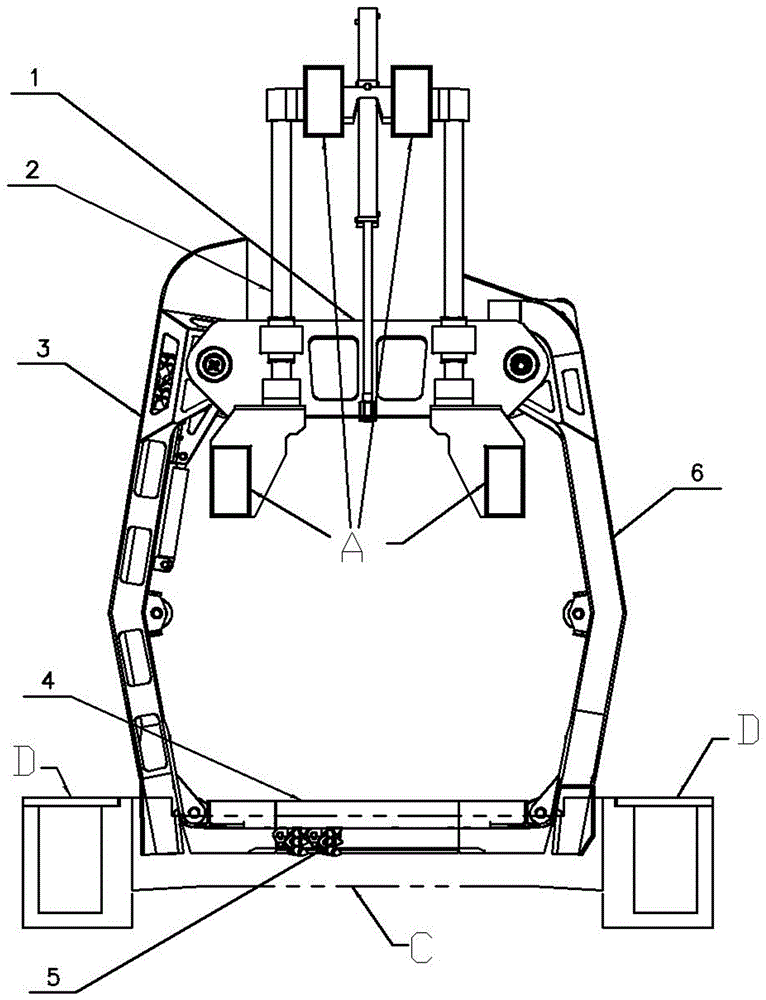

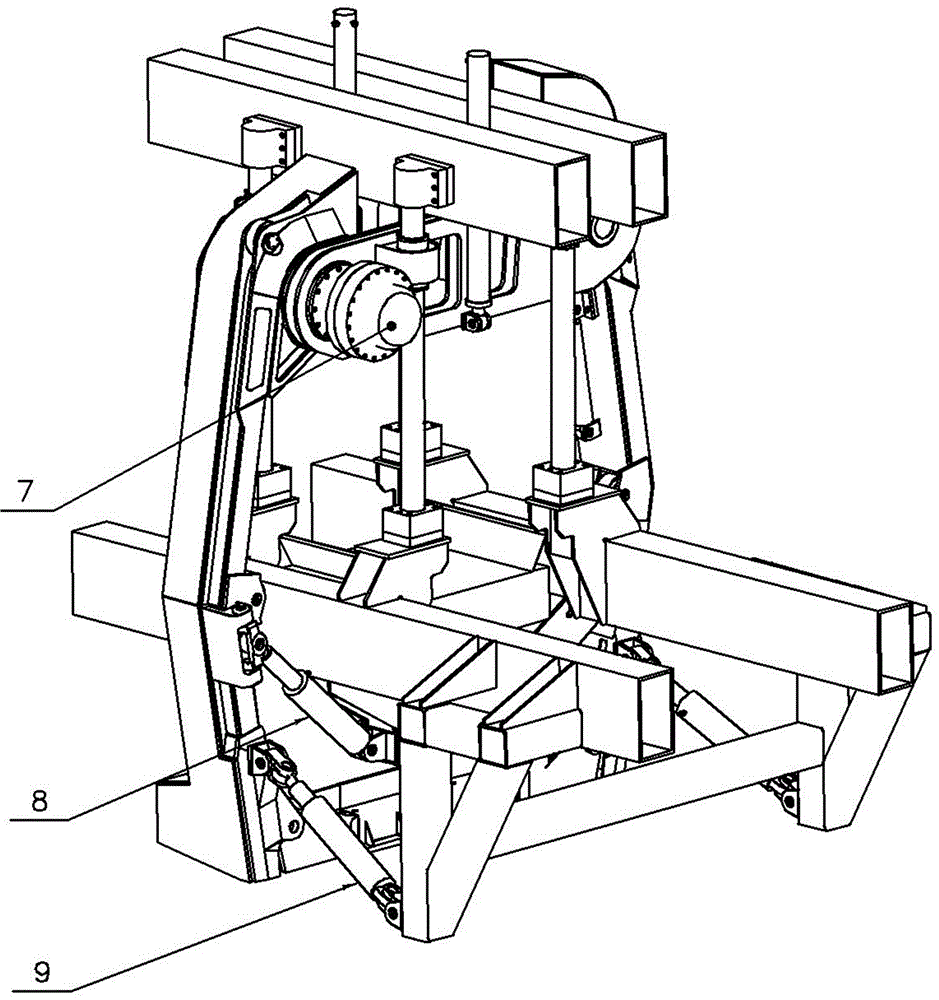

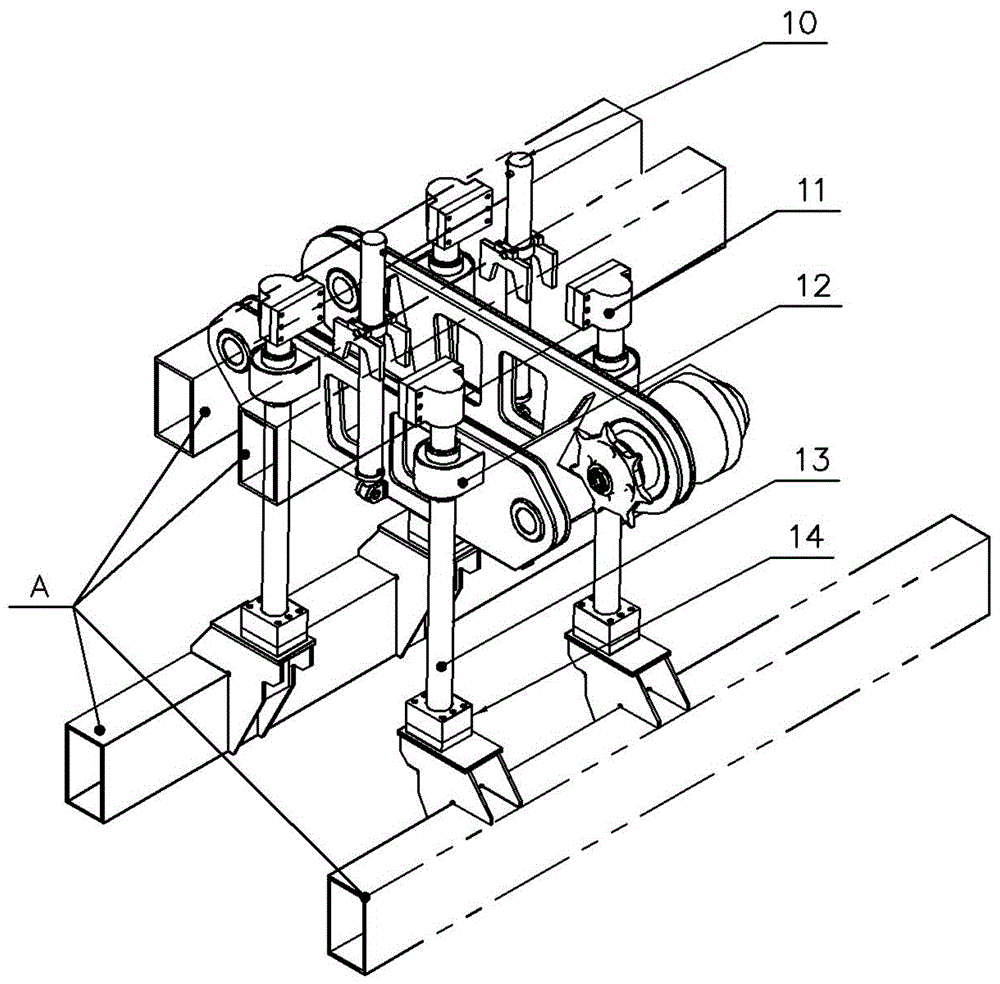

[0059] Example 1.1 Figure 1-Figure 2 It is a schematic diagram of the front structure and an axonometric view of a preferred embodiment of an excavating device adapted to the narrow working face of a railway tunnel according to the present invention. In this embodiment, an excavating device adapted to the narrow working face of a railway tunnel includes a sliding A column mechanism 2, the sliding column mechanism 2 is connected to the support beam 1, one end of the support beam 1 is connected to the ascending guide groove 6, the other end of the support beam 1 is connected to the descending guide groove 3, and the bottom ends of the ascending guide groove 6 and the descending guide groove 3 are formed by The bottom beam 4 is connected together, the ascending guide chute 6 and the descending guide trough 3 and the interior of the bottom beam 4 are equipped with an annular excavating chain 5, and the upper part of the descending guide trough 3 is also equipped with a chain tensi...

Embodiment 12

[0077] Embodiment 1.2: An excavating device suitable for operation on narrow working faces of railway tunnels. It is the same as Embodiment 1.1, except that the angle between the endless chain excavating mechanism and the cross-section of the ballast bed is 1° during operation.

Embodiment 13

[0078] Embodiment 1.3: An excavating device suitable for operation on a narrow working face of a railway tunnel. It is the same as Embodiment 1.1, except that the angle between the endless chain excavating mechanism and the cross-section of the ballast bed is 0° during operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com