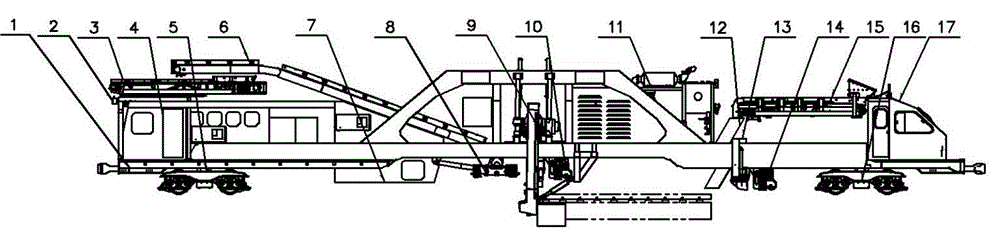

Railway ballast processor suitable for narrow operation face

A technology of working surface and processing machine, which is applied to roads, tracks, ballast layers, etc., and can solve problems such as difficulty in guaranteeing operation quality, low operation efficiency, and poor working environment for ballast processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

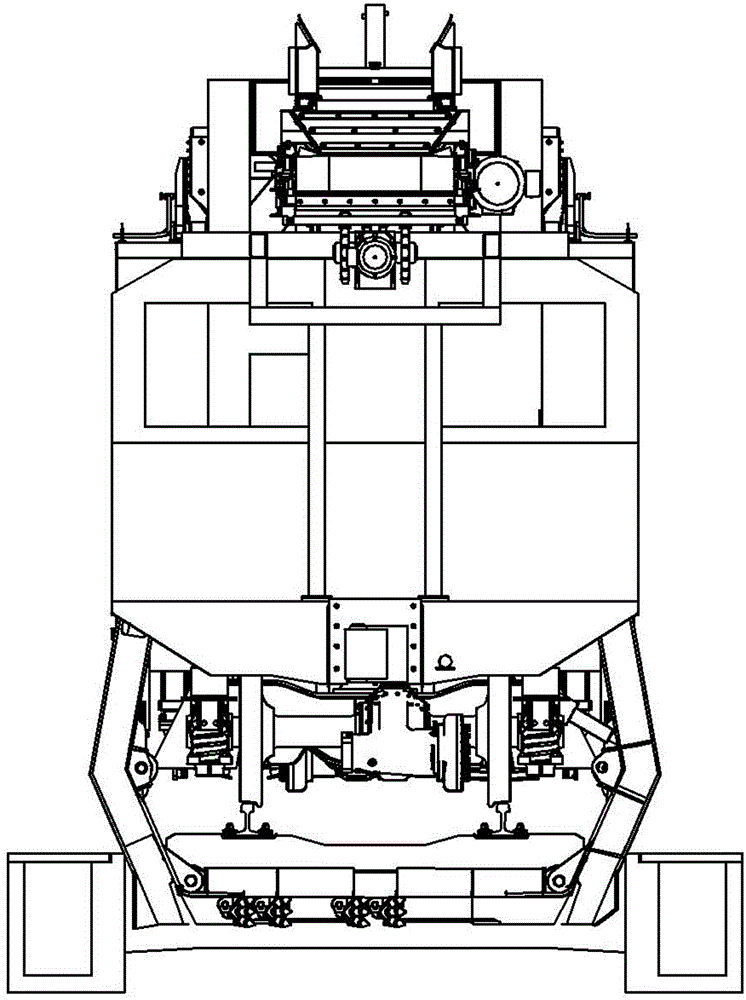

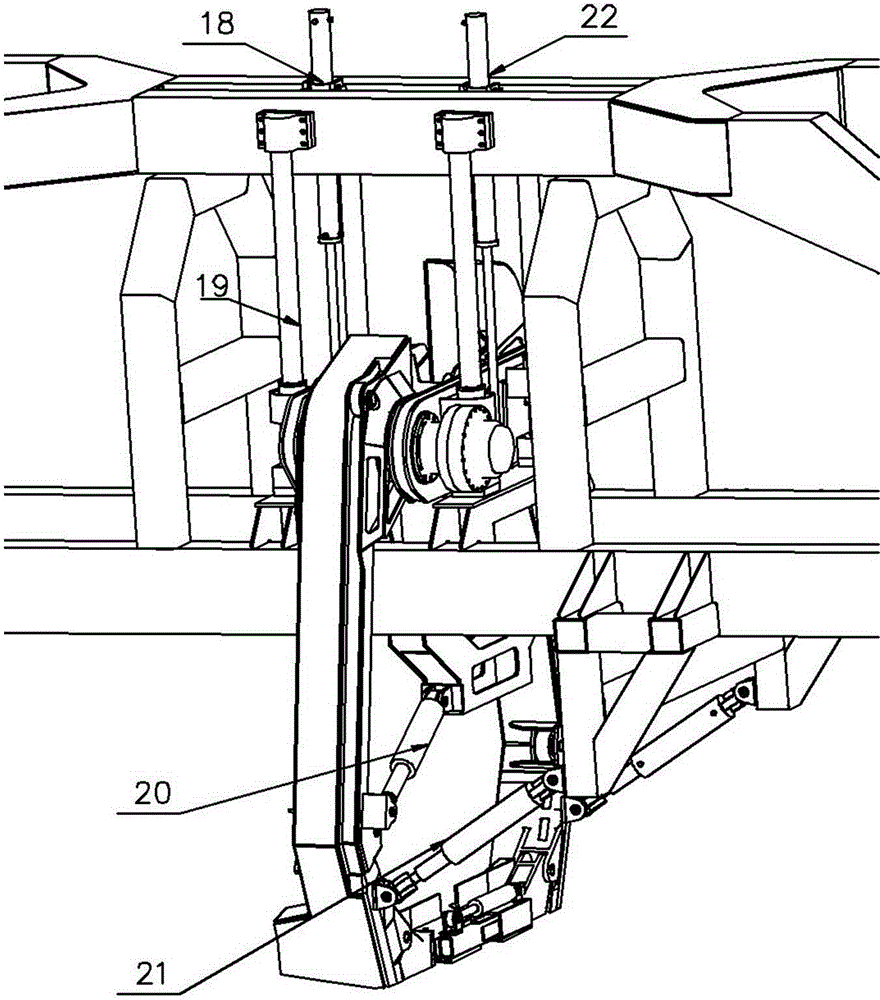

Method used

Image

Examples

Embodiment 12

[0179] Example 1.2 , a ballast processor suitable for narrow working surfaces, the same as embodiment 1.1, the difference is: the size of the included angle I is 8°.

Embodiment 13

[0180] Example 1.3 , a ballast processor suitable for narrow working surfaces, the same as embodiment 1.1, the difference is: the size of the included angle I is 10°.

Embodiment 14

[0181] Example 1.4 , a ballast processor suitable for narrow working surfaces, the same as embodiment 1.1, the difference is: the size of the included angle I is 12°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com