Plunger pump with grease stored inside

An oil column and plug pump technology, applied in the field of internally stored butter plunger pumps, can solve the problems of affecting work progress, increasing the manufacturing cost of plunger pumps, and cumbersome ways of adding butter, etc., achieving low manufacturing costs, simple structure, and improved efficiency. The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

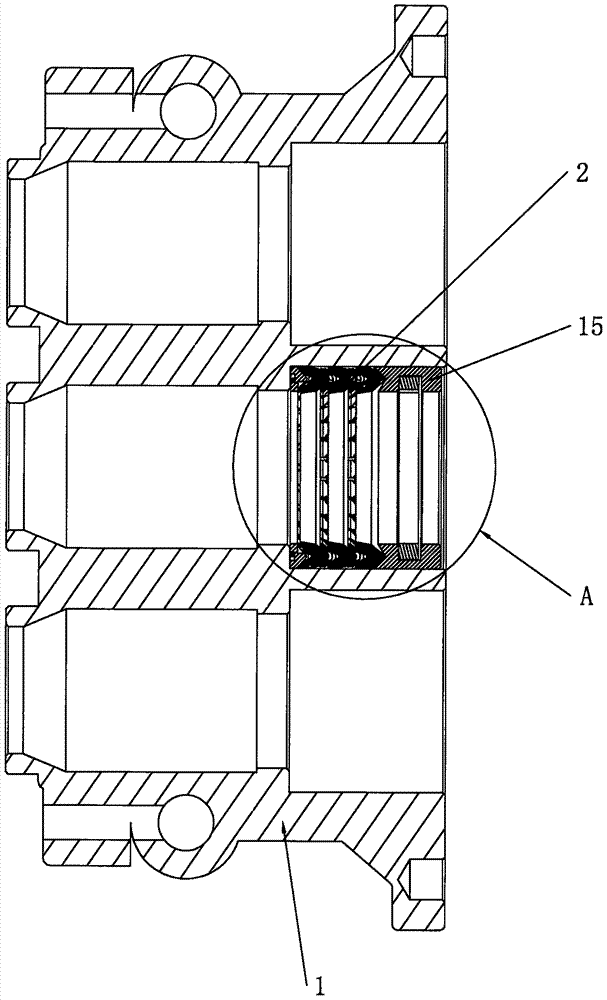

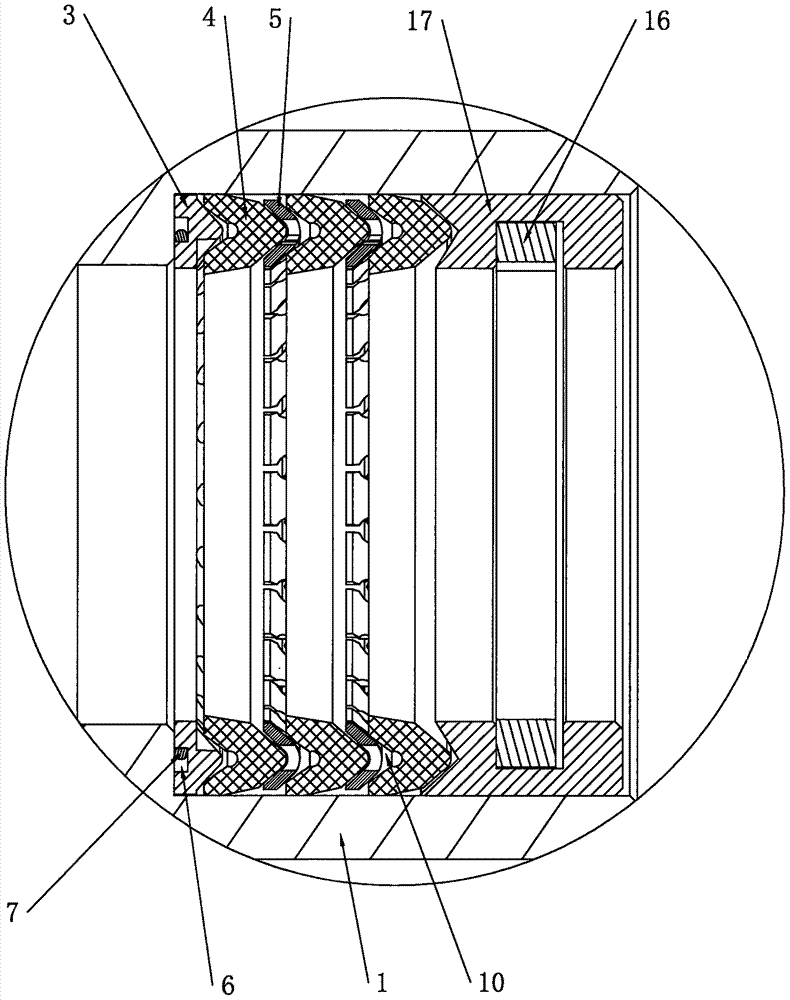

[0025] Implementation mode one: if Figures 1 to 5 As shown, the plunger pump for storing butter in the present invention includes a cylinder body 1 and a plunger arranged in the cylinder body 1. An oil storage sealing mechanism 2 is installed on the above-mentioned plunger, and the oil storage sealing mechanism 2 is connected with the plunger and the piston. Cylinder body 1 is sealed and fit; the function of the above-mentioned oil storage sealing mechanism 2 is mainly reflected in two aspects, one is the sealing function to prevent the working water from entering the plunger mechanism of the plunger pump, the other is the function of storing butter, and The storage of butter allows the plunger of the plunger pump to operate continuously, eliminating the trouble of adding butter later and improving work efficiency.

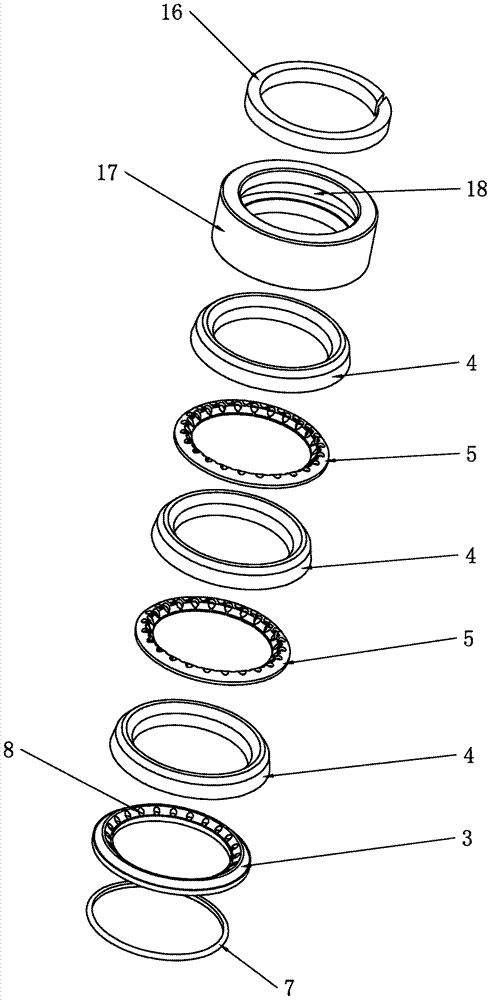

[0026] The above-mentioned oil storage sealing mechanism 2 is composed of a base ring 3, an oil seal ring 4 and a gasket 5. The above-mentioned base ring 3 is in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com