A stamping and compacting machine for floor foundation

A technology of tamping machine and stamping mechanism, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of high noise on the job site, adverse effects of buildings, etc., and achieve flexible use, good construction environment, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

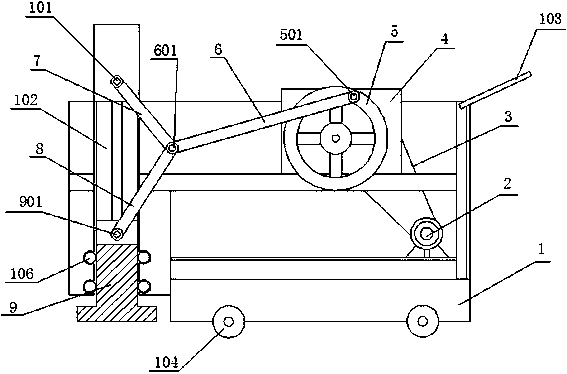

[0017] A stamping and compacting machine for floor foundations, comprising a frame 1, a power mechanism with a flywheel 5 and a booster stamping mechanism, the power mechanism and the booster stamping mechanism are both arranged on the frame 1, and the booster stamping mechanism includes a continuous Rod 6, toggle lever I7, toggle lever II8 and ram body 9, the ram body 9 is located in the slideway 102 vertically arranged inside the frame 1, and the inner wall of the slideway 102 is provided for guiding the rambody 9 to slide up and down along the slideway 102 The guide wheel 106 of the connecting rod 6, one end of the toggle lever I7 and the toggle lever II8 are hinged together through the pin II601, and the other end of the connecting rod 6 is hinged on the pin I501 on the outer edge of the flywheel 5, and the toggle lever I7 The other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com